Heat-resisting and anti-impact PPR (Polypropylene Random) pipe and preparation method thereof

An impact-resistant and heat-resistant technology, which is applied in the field of heat-resistant and impact-resistant PPR pipes and their preparation, can solve the problems of PPR pipe rigidity, tensile strength and heat-resistant performance degradation, and the degradation of PPR pipe impact resistance. Improvement of brittle defects, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

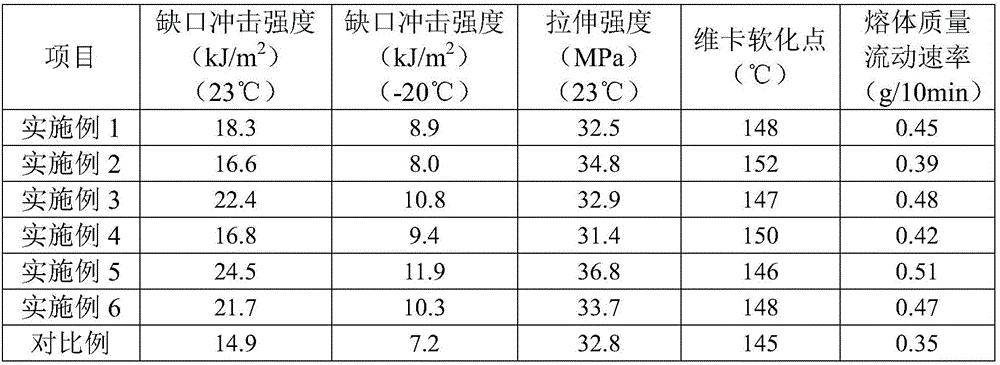

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a preparation method of the above-mentioned heat-resistant and shock-resistant PPR pipe, which includes the following steps:

[0028] In terms of parts by weight, 20-30 parts of hydrotalcite and 10-20 parts of low-molecular-weight polybutene are mixed and stirred for 2-3 minutes at 2500-3000 r / min using a mixer to obtain modified hydrotalcite; wherein, low-molecular-weight The number average molecular weight of polybutene is 2300-2550.

[0029] Mix the modified hydrotalcite with 90-120 parts of random copolymerized polypropylene and 0.8-1.5 parts of antioxidant using a mixer at 450-550r / min for 3-4 minutes to obtain a mixed material; preferably, the mixed material is modified It is prepared by mixing and stirring 90-120 parts of random copolymerized polypropylene, 0.8-1.5 parts of antioxidant and 2.6-3.6 parts of color masterbatch at 450-550 r / min for 3-4 minutes.

[0030] Extrude the mixed material with a twin-scre...

Embodiment 1

[0035] This embodiment provides a heat-resistant and shock-resistant PPR pipe, the preparation method of which is as follows:

[0036] S11. Prepare raw materials in parts by weight: 10kg random copolymer polypropylene, 1kg part of low molecular weight polybutene, 2kg hydrotalcite, 0.08kg antioxidant, 0.26kg color masterbatch; wherein, the number average of low molecular weight polybutene The molecular weight is 2327, and the antioxidant is tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester.

[0037] S12. Mix 2 kg of hydrotalcite and 1 kg of low molecular weight polybutene with a mixer at 2500 r / min for 2.5 minutes to obtain modified hydrotalcite.

[0038] S13. Mix the modified hydrotalcite with 10 kg of random copolymerized polypropylene, 0.26 kg of color masterbatch, and 0.08 kg of antioxidant using a mixer at 400 r / min for 3 minutes to obtain a mixed material.

[0039] S14. Extrude the mixed material with a twin-screw extruder and cool it to obta...

Embodiment 2

[0041] This embodiment provides a heat-resistant and shock-resistant PPR pipe, the preparation method of which is as follows:

[0042] S21. Raw materials are prepared in parts by weight: 11kg of random copolymerized polypropylene, 1kg of low molecular weight polybutene, 3kg of hydrotalcite, 0.12kg of antioxidant, 0.28kg of color masterbatch; wherein, the number average of low molecular weight polybutene The molecular weight is 2440, and the antioxidant is tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester.

[0043] S22. Mix 3 kg of hydrotalcite and 1 kg of low molecular weight polybutene with a mixer at 2700 r / min for 3 minutes to obtain modified hydrotalcite.

[0044] S23. Mix the modified hydrotalcite with 11 kg of random copolymerized polypropylene, 0.28 kg of color masterbatch, and 0.12 kg of antioxidant using a mixer at 500 r / min for 3 minutes to obtain a mixed material.

[0045] S24. Extrude the mixed material with a twin-screw extruder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com