Catalyst for preparation of natural gas from coal and preparation method thereof

A coal-to-natural gas and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve accelerated process, unsatisfactory surface wetting of coal particles, Catalyst components cannot be effectively dispersed to achieve the effect of lowering the gasification temperature, satisfying clean and efficient utilization, and accelerating the pace of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 1.0g PEG and 2.3g KHP, dissolve in 30mL deionized water, stir to dissolve completely, add 3.0g bituminous coal, heat and stir at 50°C until mixed, transfer to oven for drying, grind and sieve, mark as Sample1, and set aside.

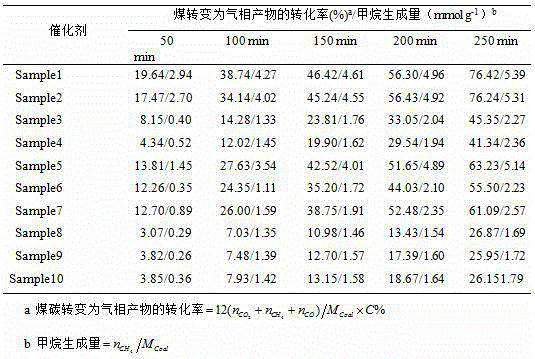

[0017] The change curve of the carbon conversion rate on the catalyst with time and the cumulative precipitation of CH4 are shown in Table 1, respectively.

Embodiment 2

[0019] Weigh 1.0g of PEG, 0.2g of SDBS and 2.3g of KHP, dissolve them in 30mL of deionized water, stir to dissolve completely, add 3.0g of bituminous coal, heat and stir at 50°C until evenly mixed, transfer to an oven for drying, grind and sieve, marked as Sample2, spare.

[0020] The change curve of the carbon conversion rate on the catalyst with time and the cumulative precipitation of CH4 are shown in Table 1, respectively.

Embodiment 3

[0022] Weigh 5.0g of PEG and 2.3g of KHP, dissolve in 30mL of deionized water, stir to dissolve completely, add 3.0g of bituminous coal, heat and stir at 50°C until evenly mixed, transfer to an oven for drying, grind and sieve, mark as Sample3, and set aside.

[0023] The change curve of the carbon conversion rate on the catalyst with time and the cumulative precipitation of CH4 are shown in Table 1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com