Heavy oil upgrading method capable of preparing methane

A processing method, methane production technology, applied in the direction of chemical instruments and methods, only multi-stage series refining and cracking process treatment, hydrocarbons, etc., can solve problems such as tail combustion safety issues, maintain self-heating balance, reduce carbon The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

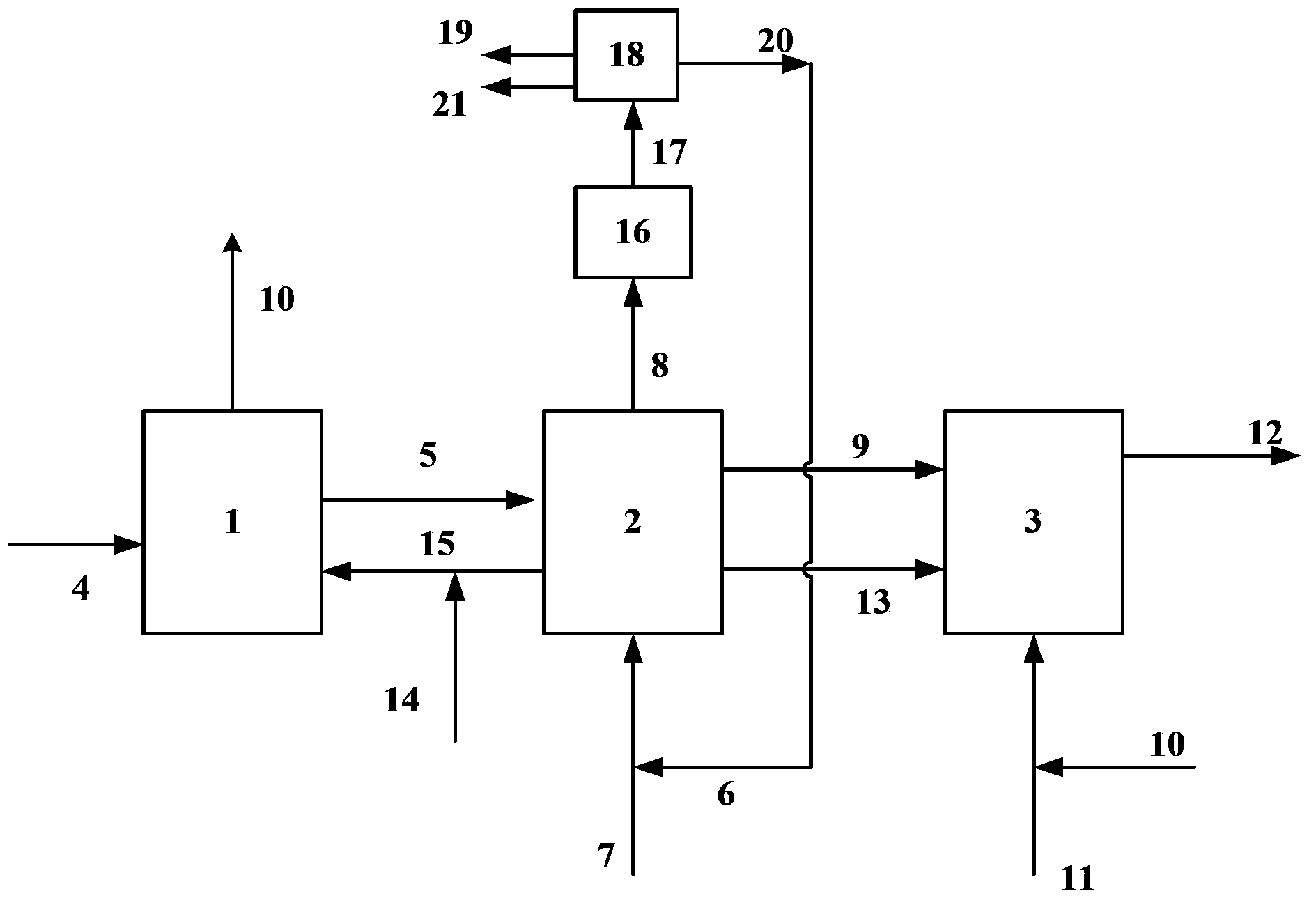

Method used

Image

Examples

Embodiment 1

[0049] The catalytic cracking catalyst with the trade name of CRC-1 was mechanically mixed with the gasification catalyst GC-3 at a mass ratio of 1:1, with a residual carbon value of 15.10% by weight, a metal content of 50 μg / g, and a sulfur content of 1.12% (by mass) The contact cracking reaction of heavy oil occurs in the contact cracking unit, and the process conditions of the contact cracking reaction are: cracking temperature 460°C, space velocity 10h -1 , the agent-oil ratio is 10, the water-oil ratio is 0.1, and the coke content of the resulting spent agent is 1.8% by weight.

[0050] The raw agent enters the fluidized bed gasifier after being stripped. The gas linear velocity of the gasifier is 0.25m / s, the gasification temperature is 620°C, and the pressure is 1.2Mpa. Water vapor is fed in as the gasification agent, and gasification and methanation reactions occur. After gas-solid separation in the gasifier, a semi-regenerated contact agent and gasification gas conta...

Embodiment 2

[0053] The catalytic cracking catalyst whose trade name is CRC-1 is mechanically mixed with the gasification catalyst GC-1, the mass ratio of the two is 3:7, and then the carbon residue value is 18.10% by weight, the metal is 200 μg / g, and the sulfur content is 1.12% (mass) heavy oil undergoes a contact cracking reaction in the contact cracking unit, and the process conditions of the contact cracking reaction are: cracking temperature 500°C, space velocity 20h -1 , the agent-oil ratio is 7, the water-oil ratio is 0.2, and the coke content of the resulting spent agent is 2.5% by weight.

[0054] The raw agent enters the fluidized bed gasifier after being stripped. The linear velocity of the gas in the gasifier is 0.12m / s, the gasification temperature is 520°C, and the pressure is 5Mpa. Water vapor is introduced as a gasification agent, and gasification and methanation reactions occur. After the gas-solid separation in the gasifier, a semi-regenerated contact agent and gasifica...

Embodiment 3

[0057] The silicon-aluminum material MFC-1 and heavy oil with a residual carbon value of 35.0% by weight, a metal content of 425 μg / g, and a sulfur content of 3.12% (mass) undergo a contact cracking reaction in a contact cracking unit. The process conditions for the contact cracking reaction are: cracking temperature 520℃, space velocity 50h -1 , the agent-to-oil ratio is 20, the water-to-oil ratio is 0.5, and the coke content of the resulting spent agent is 2.8% by weight.

[0058] The raw agent enters the fluidized bed gasifier after being stripped. The linear velocity of the gas in the gasifier is 0.4m / s, the gasification temperature is 650°C, and the pressure is 9Mpa. Water vapor is introduced as a gasification agent, and gasification and methanation reactions occur. After gas-solid separation in the gasifier, a semi-regenerated agent and gasification gas with a carbon content of 0.92% by weight are obtained. After the gasification gas is dehydrated, CH 4 The molar conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com