Grain stillage treatment system

A technology for processing system and distiller's grains, which is applied in the direction of special dry distillation, gasification process, petroleum industry, etc., can solve the problems such as not suitable for drying treatment of large quantities of distiller's grains, high load of purification device, and large dust content of flue gas, etc., and achieves improvement Energy efficiency, reduced operating load, and low gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Taking Sichuan Luzhou Laojiao distiller's grains as the raw material as the processing object:

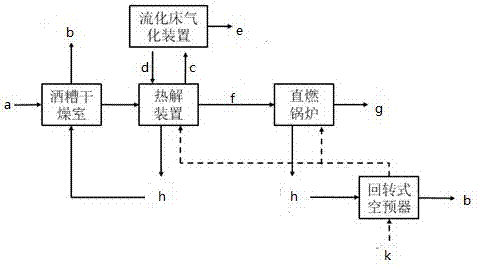

[0056] Connect the outlet of the distiller's grains drying chamber to the inlet of the pyrolysis device; the pyrolysis carbon outlet of the pyrolysis device is connected to the fluidized bed device, and the gas inlet port of the pyrolysis device is connected to the gas outlet of the fluidized bed device Connection, the oil and gas outlet of the pyrolysis device is connected to the air inlet of the direct-fired boiler, the flue gas outlet of the pyrolysis device is connected to the return pipe at the bottom of the distiller's grain drying room floor, the flue gas outlet of the direct-fired boiler is connected to the rotary The air preheater is connected; the high temperature air out of the rotary air preheater is respectively connected with the air inlet of the pyrolysis device and the air inlet of the direct-fired boiler.

[0057] A: Distiller's grains feeding and drying: Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com