Multifunctional catalysis composition

A composition and oxide technology, applied in catalytic cracking, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of high gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

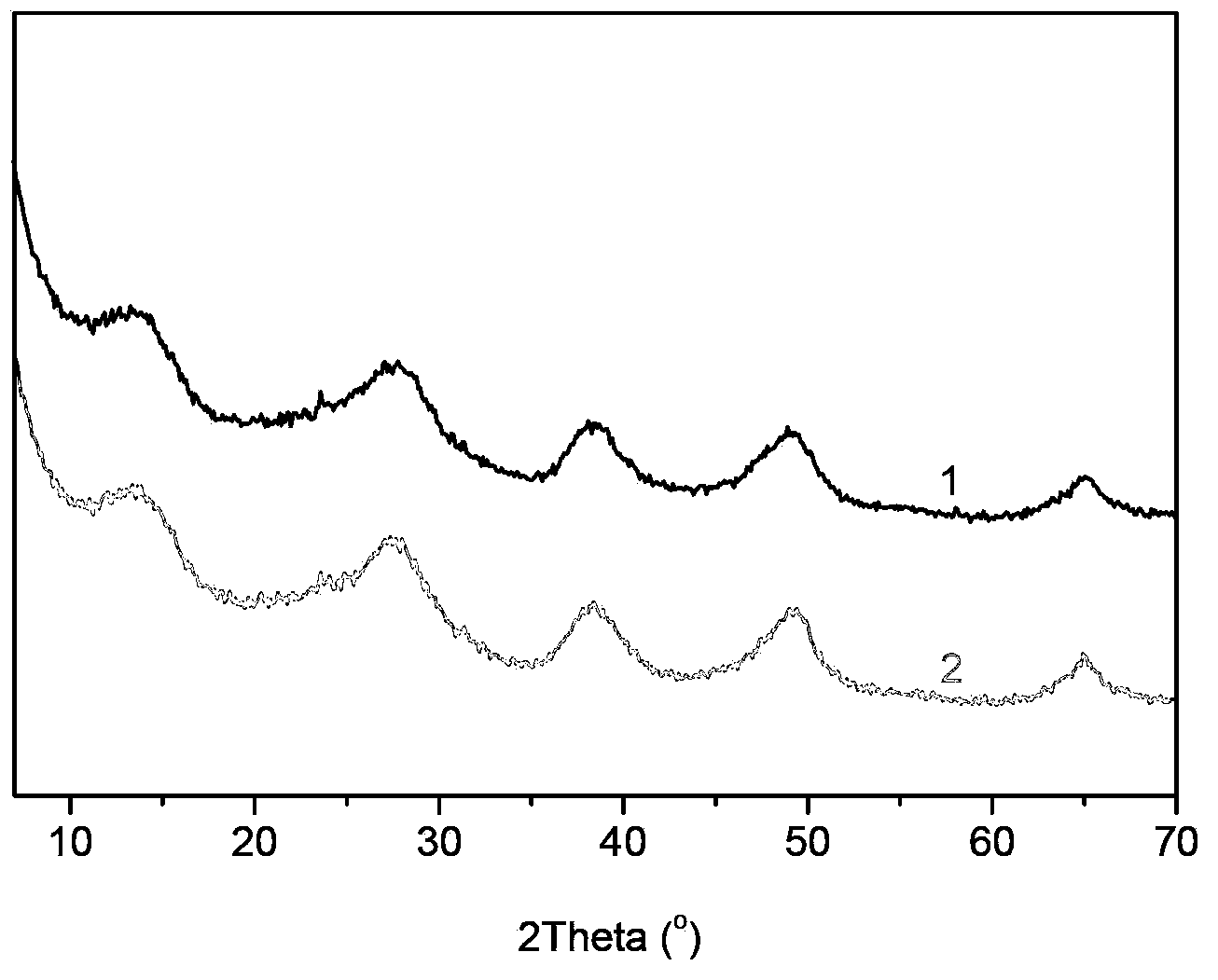

[0043] In the preparation process of the mesoporous silicon-aluminum material of the present invention, the aluminum source can be various aluminum sources conventionally used in the preparation process of the mesoporous silicon-aluminum material, for example, it can be selected from aluminum nitrate, aluminum sulfate or aluminum chloride. one or more of .

[0044] In the preparation process of the mesoporous silica-alumina material of the present invention, the silicon source can be various silica-alumina conventionally used in the preparation process of the mesoporous silica-alumina material, such as silica gel, water glass, sodium silicate, tetraethyl At least one of silicon, silicon oxide, silica sol and silica gel.

[0045] In the preparation process of the mesoporous silica-alumina material of the present invention, the alkaline solution can be various conventional alkaline solutions, for example, it can be one of ammonia water, potassium hydroxide solution, sodium metaa...

Embodiment approach

[0051] The preparation method of described catalytic composition provided by the present invention, a kind of preferred embodiment, comprises the following steps:

[0052] (1) Mix and beat the non-ion-exchanged mesoporous silica-alumina material with water to obtain a slurry, and then contact the obtained slurry with an inorganic acid at room temperature to 100°C for at least 0.2 hours to obtain a sodium oxide content of not more than 0.2% by weight A mesoporous silica-alumina material, wherein the weight ratio of the non-ion-exchanged mesoporous silica-alumina material, water and inorganic acid is 1:5-30:0.03-0.3;

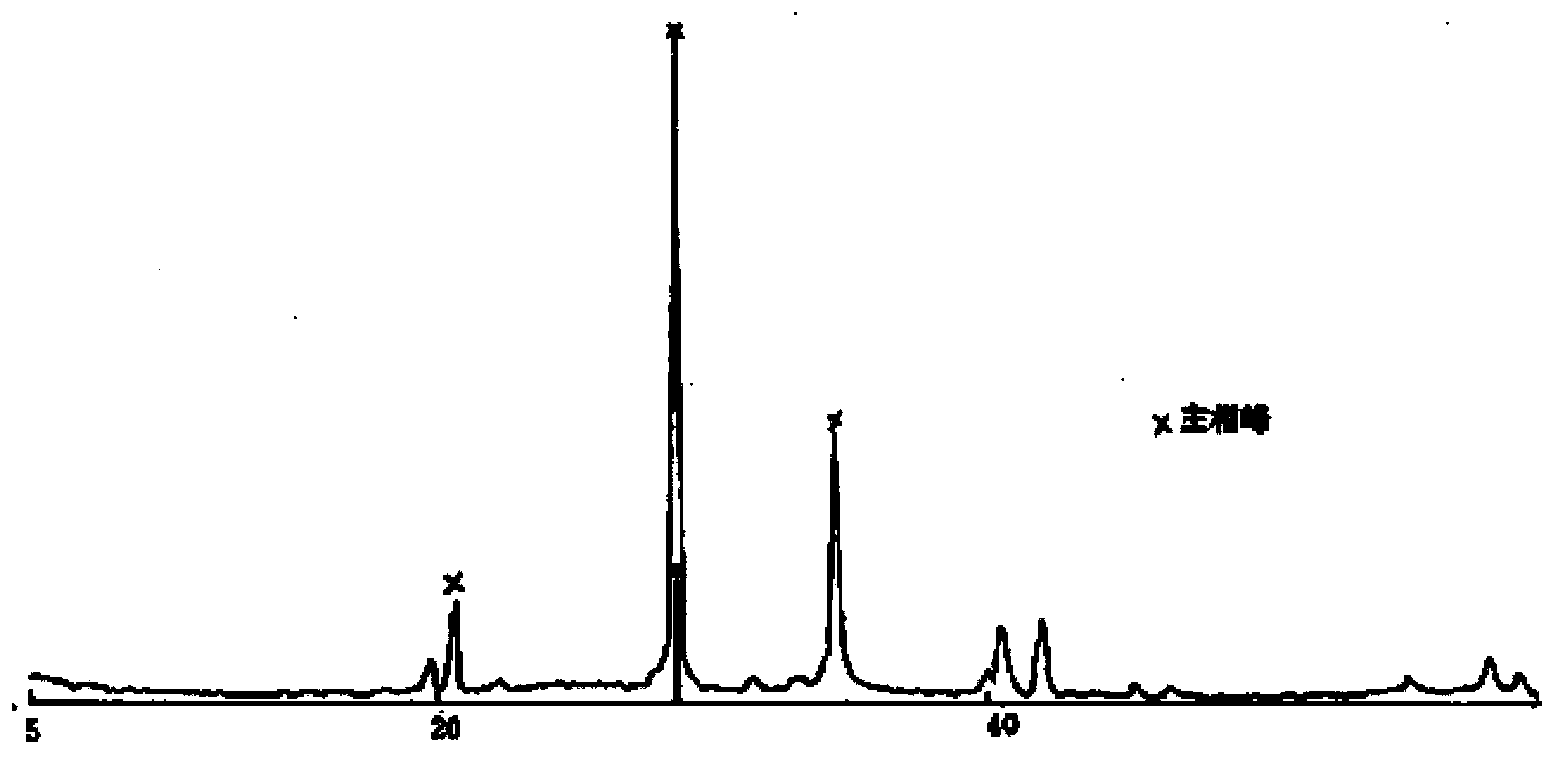

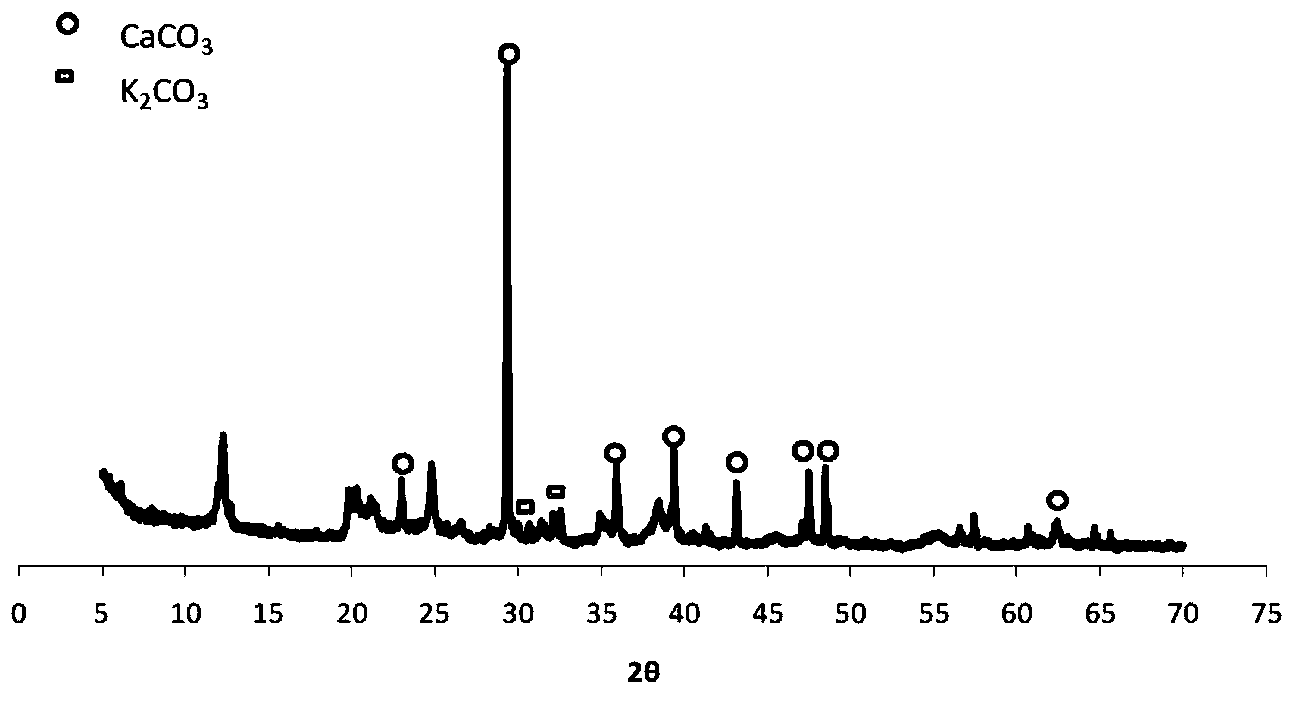

[0053] (2) Mix and beat potassium-containing compounds, alkaline earth metal compounds and silicon-aluminum components, then dry them into dry materials, and then roast them at 800°C~1150°C, preferably 900°C~1100°C for 1~10 hours, and then get Potassium-containing gasification active components; wherein the molar ratio of alkaline earth metal compounds calculated ...

preparation Embodiment 1

[0068] The mesoporous material SA-2 was prepared according to the preparation method of the mesoporous material in Example 2 published by CN1565733A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com