Optical fiber perform doper and doping method

A technology of optical fiber preform and heating evaporation, which is applied in the direction of manufacturing tools and glass manufacturing equipment, can solve the problems of large background loss, high cost, complex technology, etc., to ensure consistency and uniformity, prevent condensation and pre-reaction, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

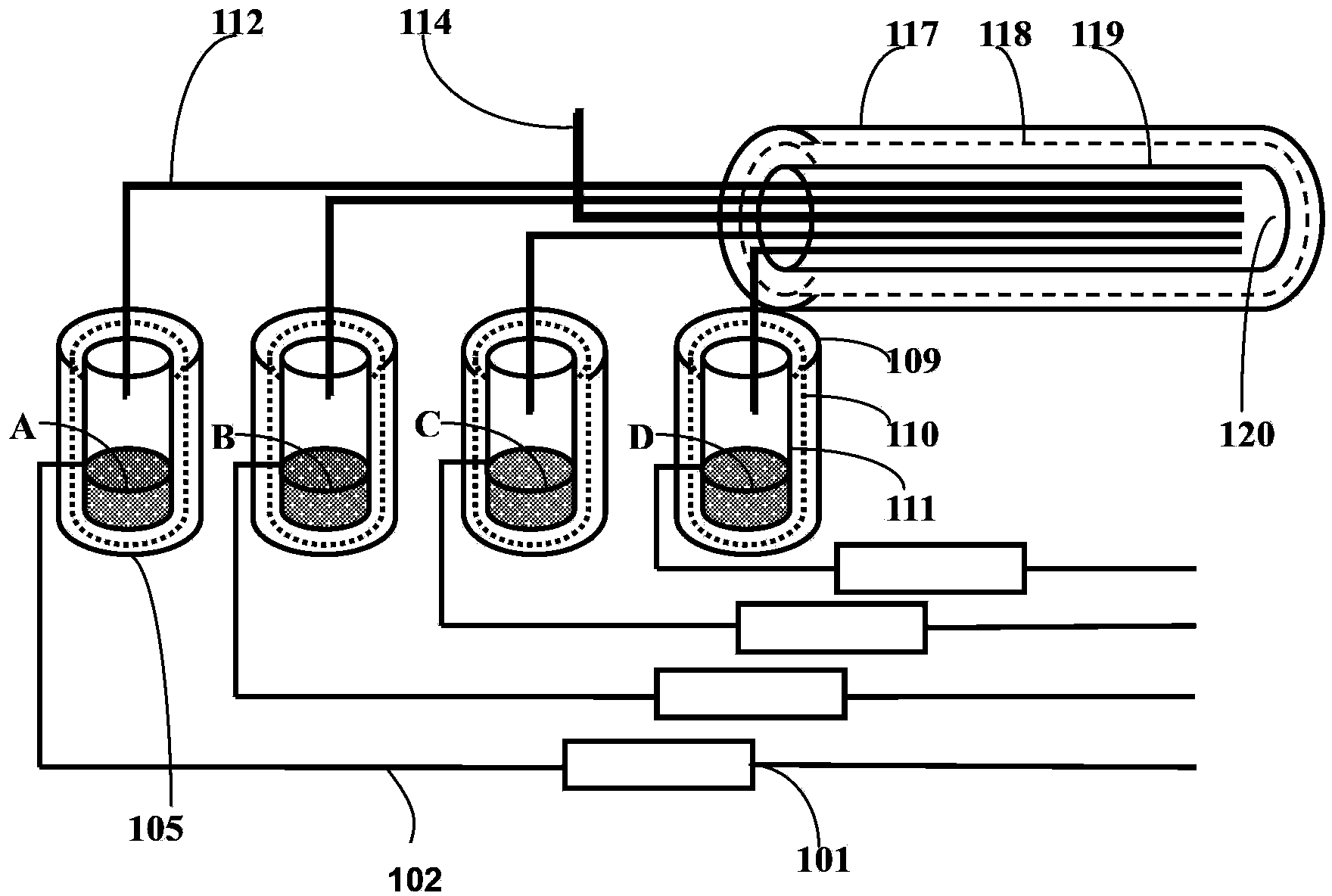

Method used

Image

Examples

example 1

[0064] The preparation of the ytterbium-doped optical fiber preform of example 1 core diameter 2mm

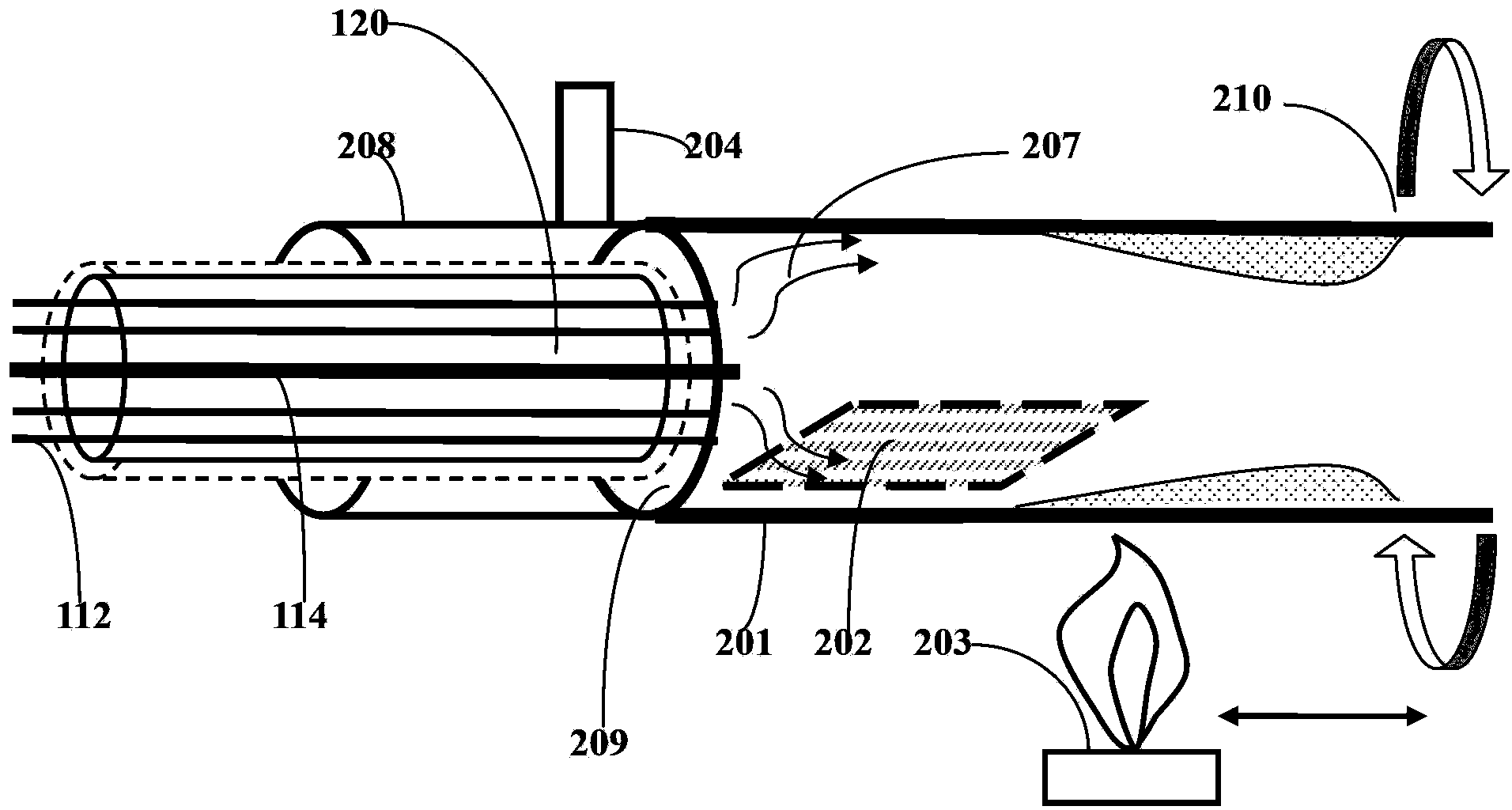

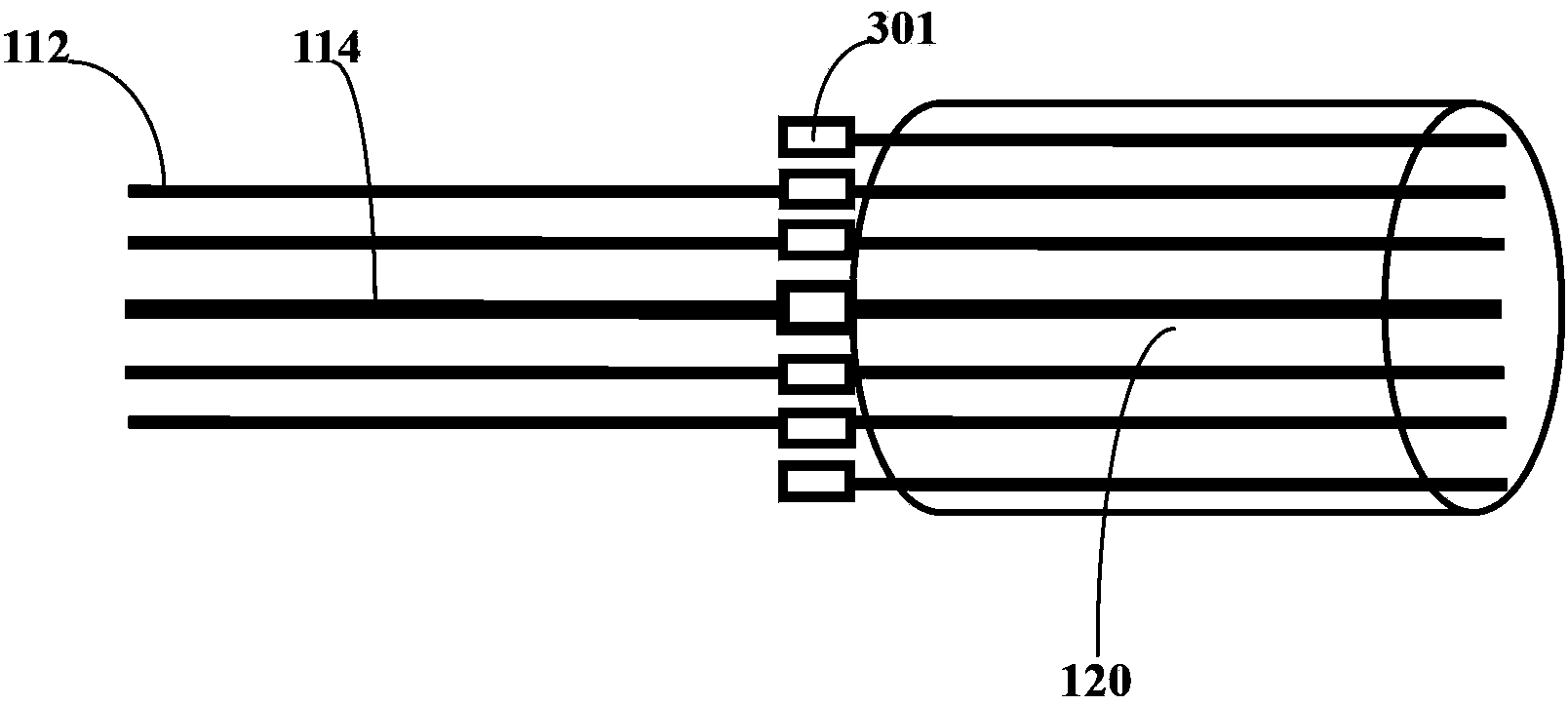

[0065] First the polishing dry gas SF 6 and Cl 2 Pass into the quartz deposition tube 201, adjust the temperature of the heating torch 203 to polish and dry the deposition tube 201; then the substrate deposition gas SiCl 4 , O 2 , SF 6 , He is passed into the quartz deposition tube 201 from the conduit interface 204, and the temperature of the heating torch 203 is set between 1350-1850°C. In this embodiment, the temperature of the heating torch 203 is selected to be adjusted at 1550°C, and 6 layers of SiO are deposited. 2 The powder layer is used as the cladding part of the optical fiber preform, deposited for 1.5 hours; then the matrix is deposited with gas SiCl 4 , O 2 , SF 6 , He, POCl 3 While passing into the quartz deposition tube 201 from the conduit interface 204, adjust the temperature of the heating evaporation tank 105 to be 210° C., the flow rate of the carr...

example 2

[0071] The preparation of the ytterbium-doped optical fiber preform of example 2 core diameter 4mm

[0072] First the polishing dry gas SF 6 and Cl 2 Pass into the quartz deposition tube 201, adjust the temperature of the heating torch 203 to polish and dry the deposition tube 201; then the substrate deposition gas SiCl 4 , SF 6 , O 2 , He, Cl 2 , POCl 3 Pass it into the quartz deposition tube 201, set the temperature of the heating torch 203 between 1450-1750°C, and adjust the temperature of the heating torch 203 at 1600°C in this embodiment, and deposit 8 layers of SiO 2 The powder layer is used as the cladding part of the optical fiber preform, deposited for 2 hours; then the matrix is deposited with gas SiCl 4 、GeCl 4 , SF 6 , O 2 , He, POCl 3While passing through the quartz deposition tube 201, set the temperature of the two heating evaporation tanks 105 at 200°C and 220°C respectively, and adjust the flow rate of the flow controller of the corresponding air i...

example 3

[0079] Preparation of ytterbium-doped optical fiber preform with core diameter 7mm of example 3

[0080] First the polishing, drying gas SF 6 and Cl 2 Pass into the quartz deposition tube 201, adjust the temperature of the heating torch 203 to polish and dry the deposition tube 201; then the substrate deposition gas SiCl 4 , SF 6 , O 2 , He, Cl 2 、BBr 3 Pass it into the quartz deposition tube 201, set the temperature of the heating torch 203 between 1550-1850°C, and adjust the temperature of the heating torch 203 at 1650°C in this embodiment, and deposit 6 layers of SiO 2 The powder layer is used as the cladding part of the optical fiber preform, deposited for 1.5 hours; then the matrix is deposited with gas SiCl 4 、GeCl 4 , SF 6 , O 2 , He is passed into the quartz deposition tube 201, and the temperatures of the two heating evaporation tanks 105 are respectively set at 100°C and 210°C, and the flow rate of the flow controller of the corresponding air inlet conduit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com