Catalytic pyrolysis gasification method of urban garbage

A municipal waste, pyrolysis gasification technology, applied in gasification process, fixed bed gasification, granular/powdered fuel gasification, etc., can solve the problems of equipment corrosion, catalyst loss, etc., achieve low corrosion, reduce gas The effect of melting temperature and avoiding melting and slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

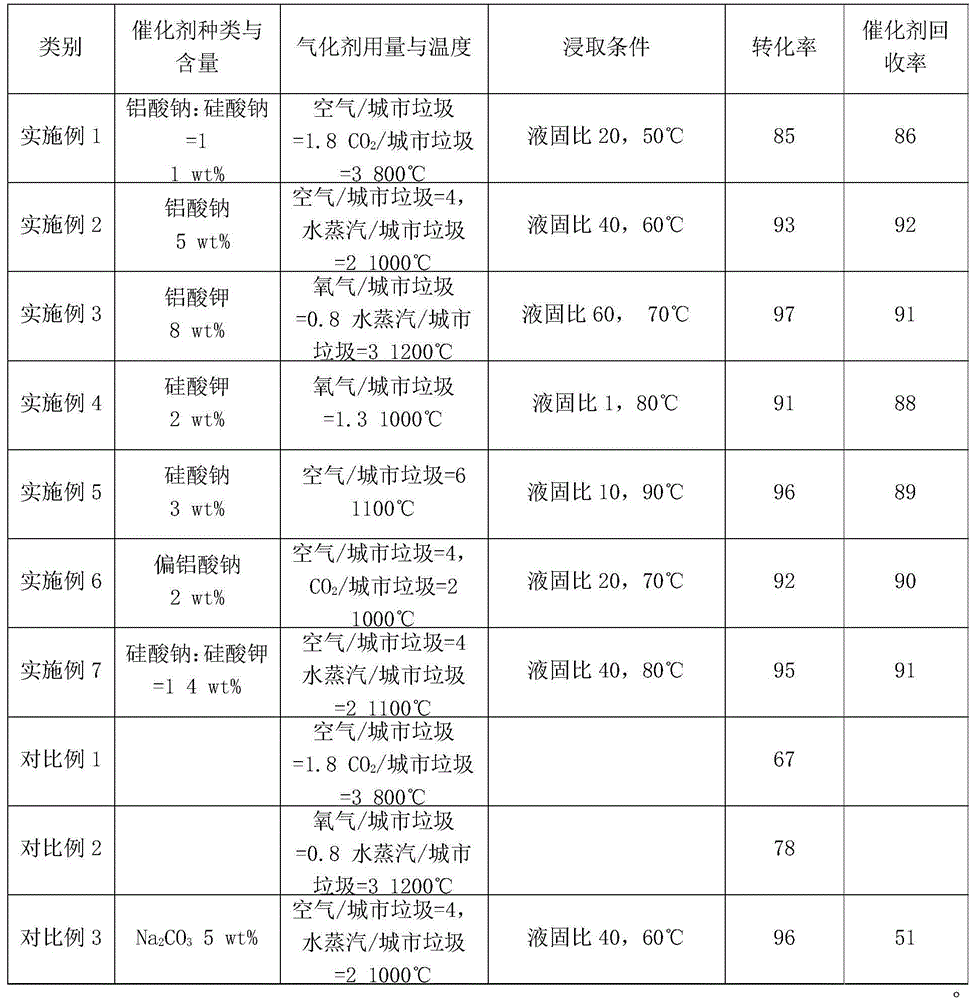

Examples

Embodiment 1

[0031] Embodiment 1: In this embodiment, municipal waste is used as a sample, sodium aluminate and sodium silicate are used as catalysts, and a fixed-bed gasifier is used to load the catalyst on the municipal waste through a solution impregnation method. The main components of the waste are shown in Table 1.

[0032] Table 1. Main components of garbage

[0033] waste paper plastic timber clothes food residue other 15.3% 21.1% 7.3% 8.1% 41.2% 7%

[0034] The catalyst loading steps are as follows:

[0035] 1) The mass ratio of sodium aluminate to sodium silicate is 1, the mass ratio of water to sodium aluminate is 40, the mass ratio of water to sodium silicate is 40, and the mixture is stirred at 60°C until completely dissolved;

[0036] 2) The mass of the alkali metal element Na is 1wt% of the mass of urban waste, and the pulverized urban waste is added to the solution, stirred and kept at temperature until a slurry-like substance is formed;

...

Embodiment 2

[0039] Example 2: In this example, municipal waste was used as a sample, sodium aluminate was used as a catalyst, and sodium aluminate was loaded onto municipal waste through a mechanical mixing method using a fluidized bed gasifier. The main components of the waste are shown in Table 1.

[0040] The catalyst loading steps are as follows:

[0041] The mass of the alkali metal element Na is 5wt% of the mass of the urban waste. The sodium aluminate and the urban waste are mixed and put into a vibrating pulverizer, and taken out after grinding for 5 minutes to obtain the catalyst-loaded urban waste prepared by the mechanical mixing method.

[0042] Take municipal waste loaded with sodium aluminate and add it to a fluidized bed gasifier for gasification. The mass of alkali metal element Na is 5wt% of the mass of municipal waste, the pressure is 3MP, the gasification temperature is 1000°C, and the gasification agent is air and water. Steam, air / municipal waste mass ratio is 4, wate...

Embodiment 3

[0043] Embodiment 3: In this embodiment, municipal waste is used as a sample, potassium aluminate is used as a catalyst, and an entrained bed gasifier is used to load potassium aluminate onto municipal waste by spraying. The main components of the waste are shown in Table 1.

[0044] The catalyst loading steps are as follows:

[0045] 1) The mass of the alkali metal element K is 8wt% of the mass of urban waste, and the catalyst solution is prepared with a mass ratio of water to potassium aluminate of 20, and heated to 80°C;

[0046] 2) Spray the prepared solution on the municipal waste in the form of spray, and dry at 80° C. for 12 hours to obtain the catalyst-loaded municipal waste.

[0047]Take the municipal waste loaded with potassium aluminate and put it into an entrained bed gasifier for gasification. The load of alkali metal K is 8wt%, the pressure is 5MP, the gasification temperature is 1200°C, the gasification agent is oxygen and water vapor, and the oxygen / The mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com