Waste oil treatment device and method thereof

A technology of oil treatment and oil cavity, which is applied in separation method, grease/oily substance/suspton removal device, water/sewage treatment, etc. It can solve problems such as unfavorable sustainable development, failure to absorb oil film, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

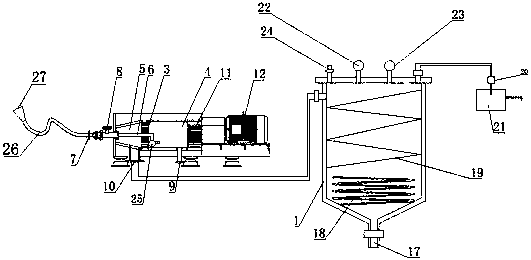

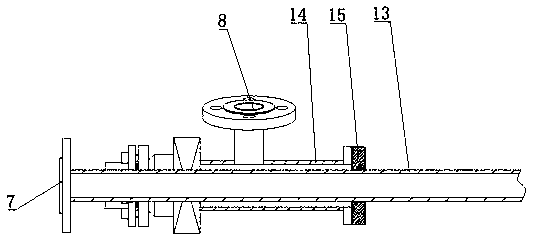

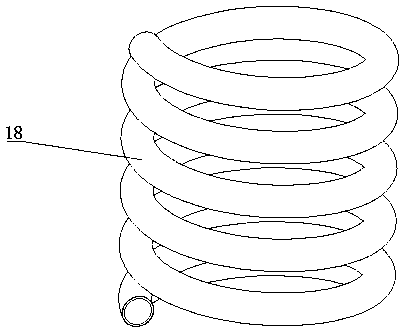

[0024] Example: such as Figure 1-4 As shown, a waste oil treatment device includes a separation chamber and a distillation chamber 1, the separation chamber is connected with a feed port 7, a water outlet 8, a slag outlet 9 and an oil outlet 10, and the distillation chamber 1 is provided with Oil inlet, the oil outlet 10 communicates with the oil inlet, such as figure 1 As shown, the waste oil entering the distillation chamber 1 is separated from most of the slag and water through the separation chamber in advance, which can effectively reduce the waste residue in the distillation chamber 1, greatly prolong the opening frequency of the waste outlet 17 of the distillation chamber 1, and improve The production efficiency is improved, and the slag discharge in the separation chamber is carried out at room temperature, which can effectively reduce the probability of safety accidents. Such as figure 1 As shown, the middle part of the separation chamber is provided with a partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com