Clean synthesis gas and preparation method thereof

A synthesis gas and clean technology, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of secondary pollution, high volatile content of biomass, low energy density, etc., improve utilization rate, and contribute to CO2 reduction row, achieve large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

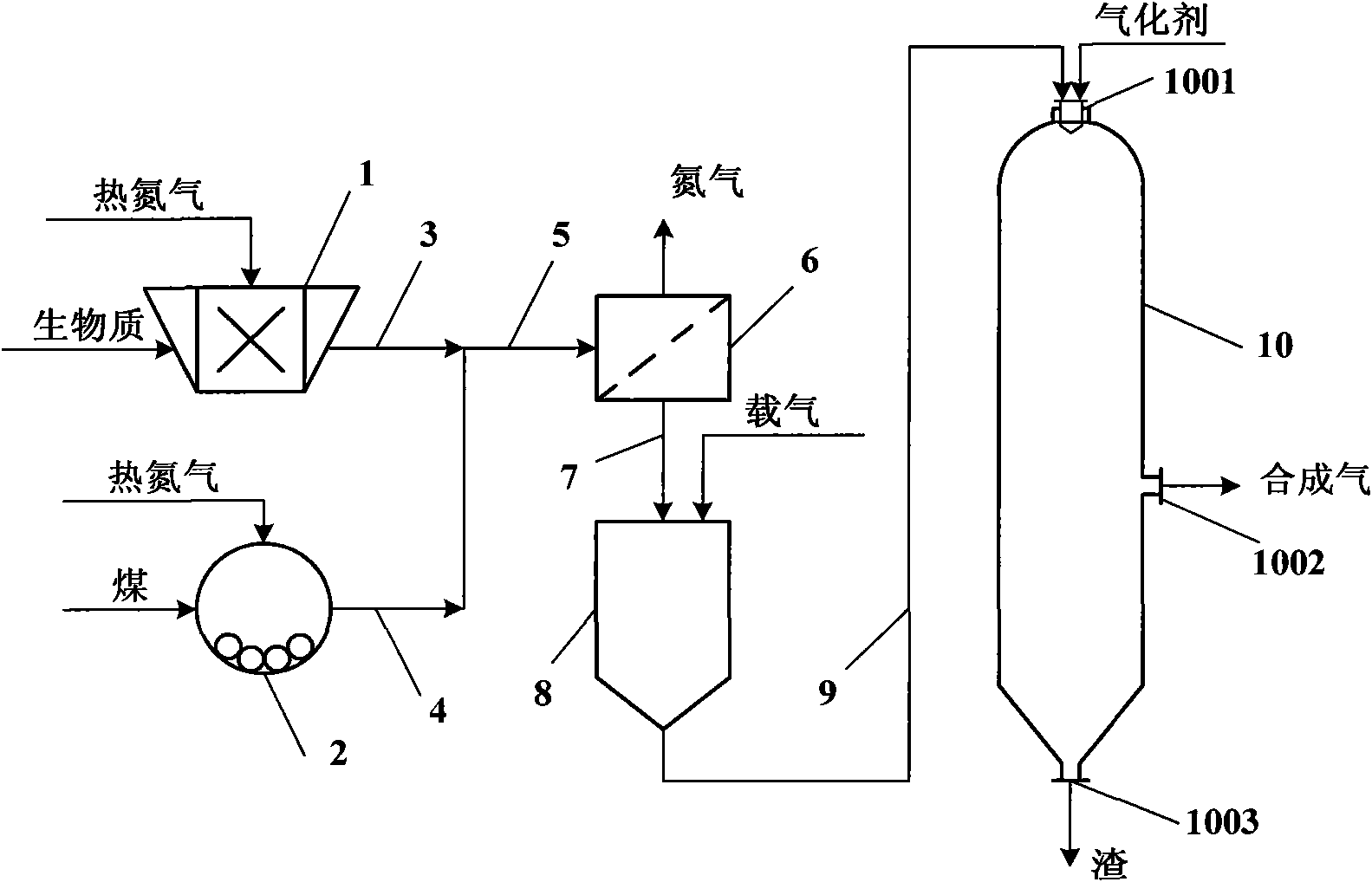

[0031] use figure 1 process. Biomass was pine wood waste from wood processing plants.

[0032] Clean synthesis gas is prepared by:

[0033] 1. Grind the waste pine wood to 2-3 mm in the pulverizer 1, and dry it with nitrogen gas at 150° C. until the water content is 10.0 wt % to obtain dried pine wood chips; grind the coal through the ball mill 2 to an average particle size of 0.1 mm , while drying by 150°C heat-carrying nitrogen to a moisture content of 10.0wt%, to obtain dry coal powder;

[0034] 2. Under the carrying effect of nitrogen, the dried pine wood chips and the dried coal powder are respectively passed through the pipeline 3 and the pipeline 4 to the pipeline 5 to complete uniform mixing to obtain mixed granules, wherein the dried pine wood chips account for 40% of the mass of the mixed granules;

[0035] 3. The gas-solid separation of the mixed particles is realized in the bag filter 6, and the separated nitrogen gas is discharged from the system, and the mixed...

Embodiment 2

[0039] Adopt the same flow process as embodiment 1. The biomass is straw.

[0040] Clean synthesis gas is prepared by:

[0041] 1. The rice straw is pulverized to about 3 mm in the pulverizer 1, and simultaneously dried by 250° C. heat-carrying nitrogen until the water content is 0.0 wt % to obtain dried rice straw particles; Drying at 250°C with heat-carrying nitrogen until the water content is 0.0wt%, to obtain dried coal powder;

[0042] 2. The dried straw granules and the dried pulverized coal are respectively passed through the pipeline 3 and the pipeline 4 to the pipeline 5 under the carrying action of nitrogen to complete the uniform mixing to obtain the mixed granules, wherein the content of the straw granules is 5% of the mixed granule mass;

[0043] 3. The gas-solid separation of the mixed particles is realized in the bag filter 6, and the separated nitrogen gas is discharged from the system, and the mixed particles enter the material tank 8 through the pipeline 7;...

Embodiment 3

[0047] Adopt the same flow process as embodiment 1. Biomass was a mixture of straw and pine wood (1:1 by weight).

[0048] Clean synthesis gas is prepared by:

[0049] 1. Grinding the biomass to 1-2mm in the pulverizer 1, and simultaneously drying it with nitrogen gas at 220°C until the water content is 4.0wt%, to obtain dry biomass particles; grinding the coal through the ball mill 2 to an average particle size of 58 μm , while drying by 220°C heat-carrying nitrogen to a moisture content of 4.0wt%, to obtain dry coal powder;

[0050] 2. The dried biomass granules and the dried coal powder are carried by nitrogen gas respectively through the pipeline 3 and the pipeline 4 to the pipeline 5 to complete the uniform mixing to obtain the mixed granules, wherein the mass of the biomass granules accounts for 0.1% of the mass of the mixed granules. %;

[0051] 3. The gas-solid separation of the mixed particles is realized in the bag filter 6, and the separated nitrogen gas is disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com