Automatic garbage screening, guiding and compartmenting pyrolysis device

A technology of automatic screening and garbage, applied in lighting and heating equipment, combustion method, combustion type, etc., can solve the problems of high cost, dioxin organic garbage blocking, high power of induced draft fan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

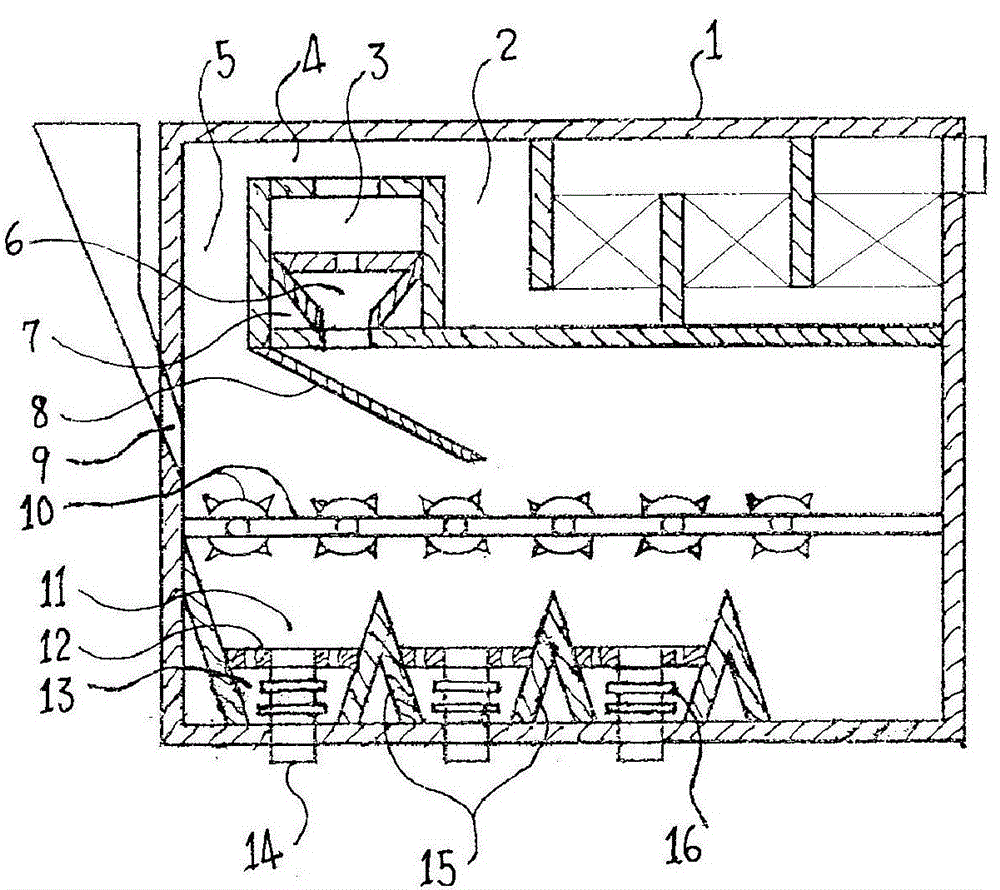

[0025] Such as figure 1 As shown, the garbage automatic sieving guide chamber pyrolysis device of the present invention includes a cavity 1 with a garbage inlet 9, and the garbage inlet 9 is arranged on the left side wall of the cavity 1 (facing the figure 1), under the side of the garbage inlet 9, a screening mechanism 10 is provided to make the garbage move horizontally, screen and pyrolyze (when the garbage inlet 9 is set at the top wall of the cavity near the side wall, the screening mechanism 10 can be set at the garbage inlet 9), the sieving mechanism 10 is connected with the hot air conveying mechanism, the sieving mechanism 10 has six sieve rollers arranged at intervals in the transverse direction and moves in the same direction, and a solid-phase pyrolysis chamber 15 is provided under the sieving mechanism 10, where A gas phase pyrolysis chamber 3 and a wet gas channel 5 are arranged above the screening mechanism 10 , and a downwardly protruding guide compartment 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com