Treatment method for waste circuit board pyrolysis recovery

The technology of a waste circuit board and a treatment method, which is applied in the treatment field of waste circuit board pyrolysis recovery, can solve problems such as environmental pollution, and achieve the effects of improving metal recovery rate, avoiding dioxin production, and reducing processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

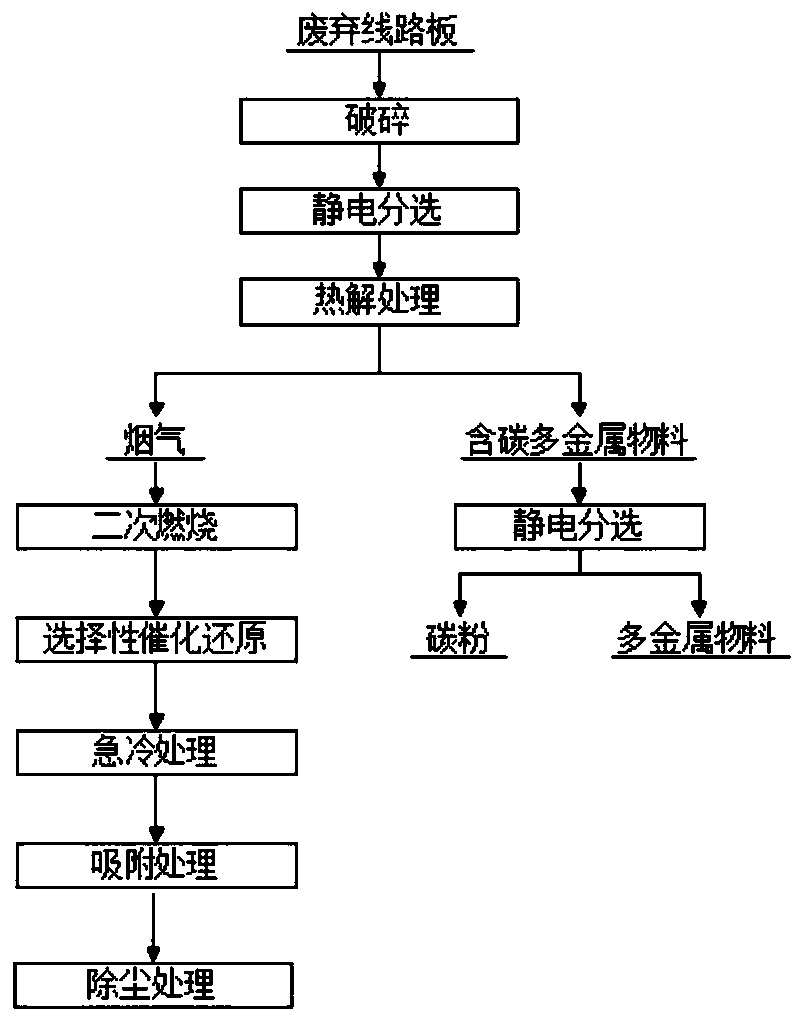

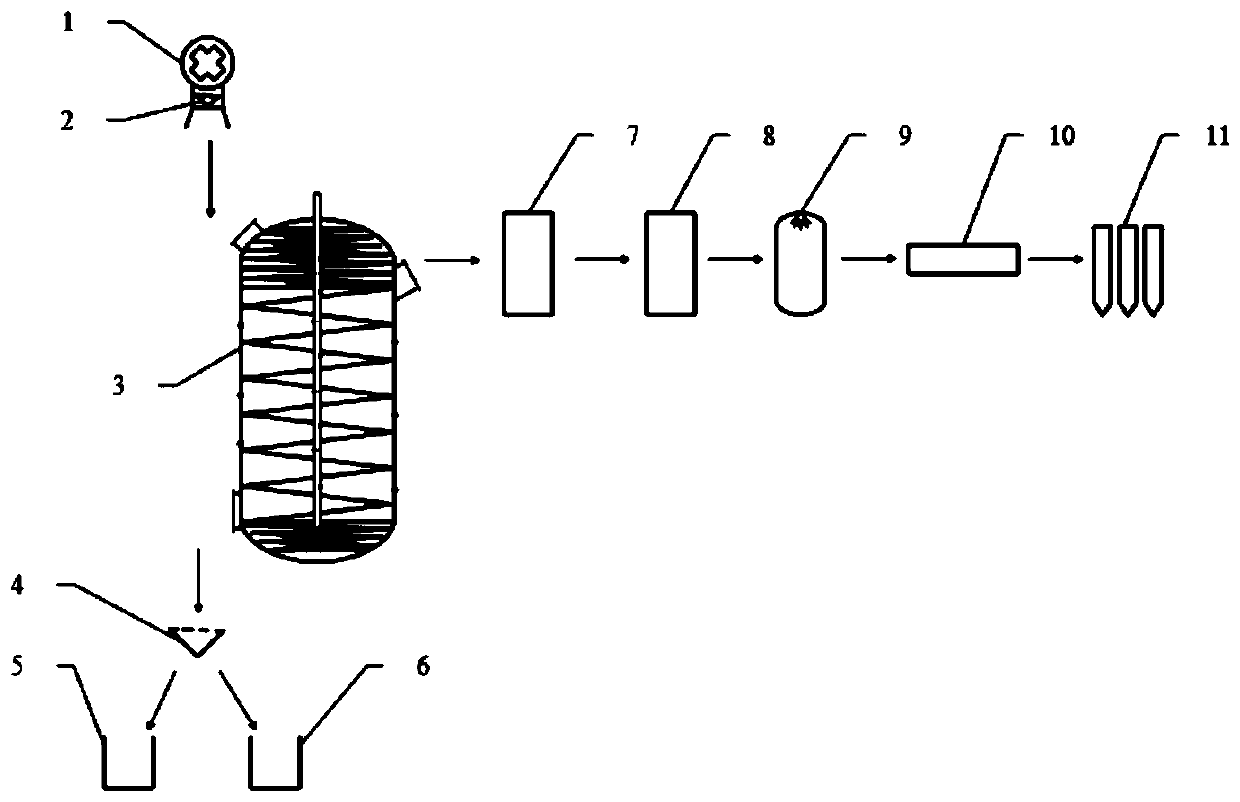

[0043] A treatment method for waste circuit board pyrolysis recovery of the present invention, such as figure 1 and 2 shown, including the following steps:

[0044] (1) Use the first rotary hammer crusher 1 to crush the entire waste circuit board into small pieces with a diameter of 1-2mm, and then use the first high-voltage electrostatic metal separator 2 to carry out electrostatic separation, so that the waste The total content of resin and glass fiber in the circuit board is reduced from 60% to 80% to 20% to 30%, and metal-containing concentrates and small plastic plates are obtained;

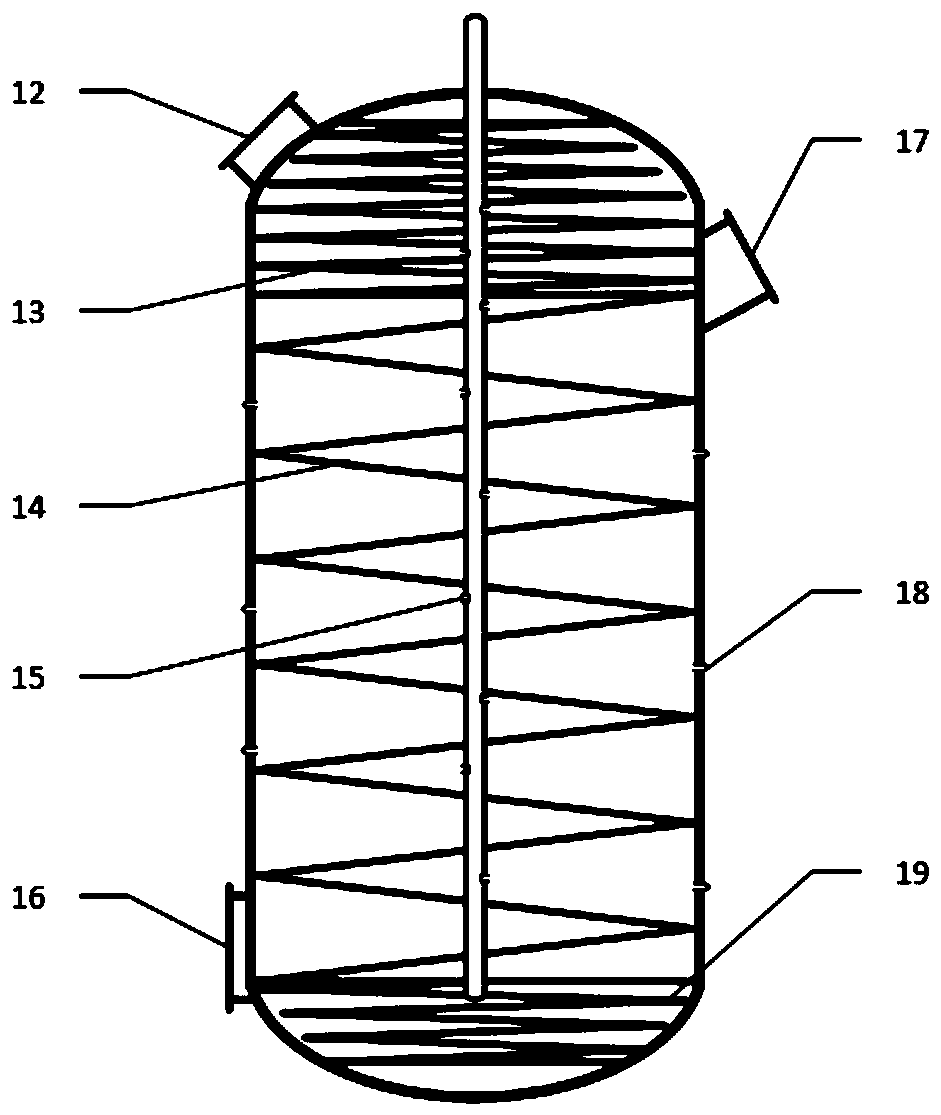

[0045] (2) Precisely control the temperature of the fine material obtained after the electrostatic sorting in the step (1) and perform pyrolysis treatment under the anaerobic condition of 600°C. The pyrolysis treatment is carried out in the pyrolysis furnace 3, and the pyrolysis time is 10 -15min, to obtain flue gas and carbon-containing polymetallic powder formed by pyrolysis;

[0046] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com