Coal pyrolysis method and system

A pyrolysis and pyrolysis reactor technology, applied in the field of pyrolysis coal, can solve the problems of high tar yield, reduced processing cost, and high energy consumption, and achieve the effects of high tar yield, reduced processing cost, and high-efficiency pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

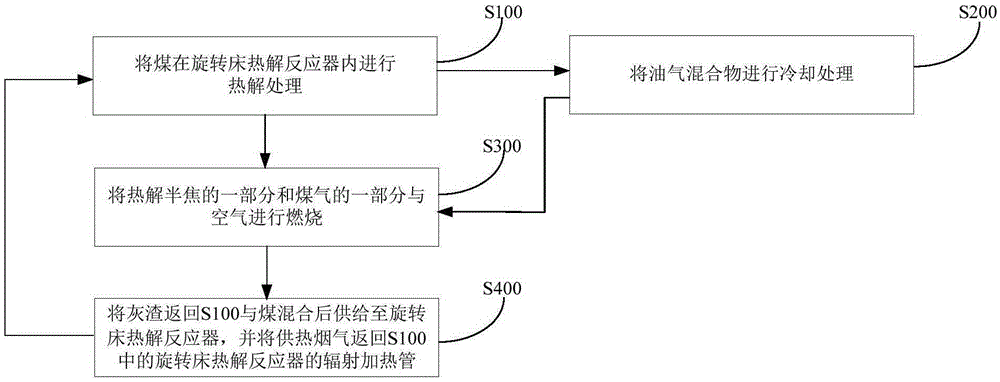

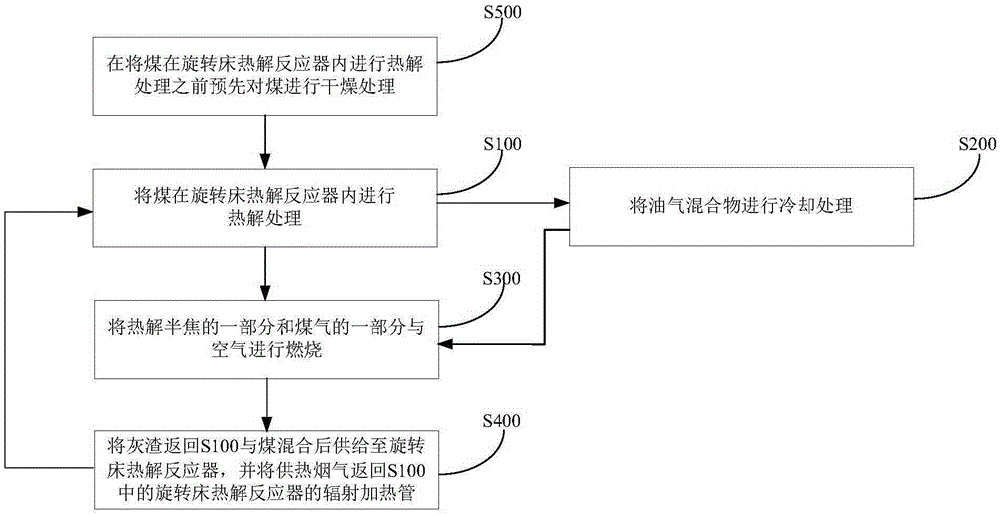

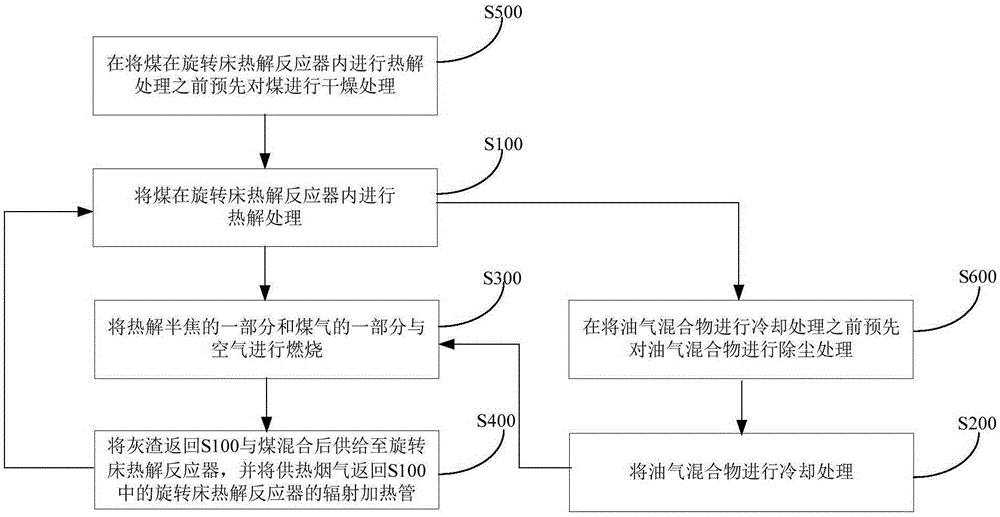

Method used

Image

Examples

Embodiment

[0097] refer to Figure 12 , store lignite in coal bunker 1, and then store lignite (V d =41.35%, Q gr,d =24.8MJ / kg) is supplied to the drying bin 2 for drying treatment, and then the dried lignite (moisture<8%) is supplied to the rotary bed pyrolysis reactor 4 through the radiation heating tube 15 on the rotary bed pyrolysis The lignite in the reactor 4 is radiated and heated to undergo a pyrolysis reaction (500-650° C.) (the product yield is shown in Table 1), and the resulting oil-gas mixture enters the high-temperature dust collector 5 through the pipe at the top of the rotating bed pyrolysis reactor 4 Purify to obtain dust-removed oil gas and semi-coke particles, then pass the dust-removed oil gas into the oil-gas cooler 6 to cool down, and obtain coal tar and raw coal gas after separation, and the raw coal gas is partially sent to the combustion bed 8 after being purified by the raw coal gas purification unit 7 Combustion after mixing with the air from the fan 9, heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com