Oxygen-free sticky garbage pyrolyzing method and system

A technology for catalytic thermal cracking and waste, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., to achieve the effect of increasing the calorific value of gas, simple operation and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention adopts an anaerobic pyrolysis technology of viscous waste, which is a process of heating, distilling, carbonizing and decomposing organic solid waste, such as waste paint, ink and oil sludge, under anaerobic conditions. This process is a complex chemical reaction reduction process. Including the bond breaking of macromolecules, isomerization and polymerization of small molecules, etc., and finally generate various smaller molecules, mainly including: 1. Combustible gases mainly composed of low-molecular hydrocarbons such as hydrogen, carbon monoxide, and methane ; 2. Organic substances that are liquid at room temperature, including compounds such as acetone acetate; 3. Solid biological carbon, glass, metal, soil sand, etc. The result is that all organic matter, including plastics, rayon, paper, animal and plant waste, etc., is broken down into water, fuels like liquefied gas, and specialty carbons.

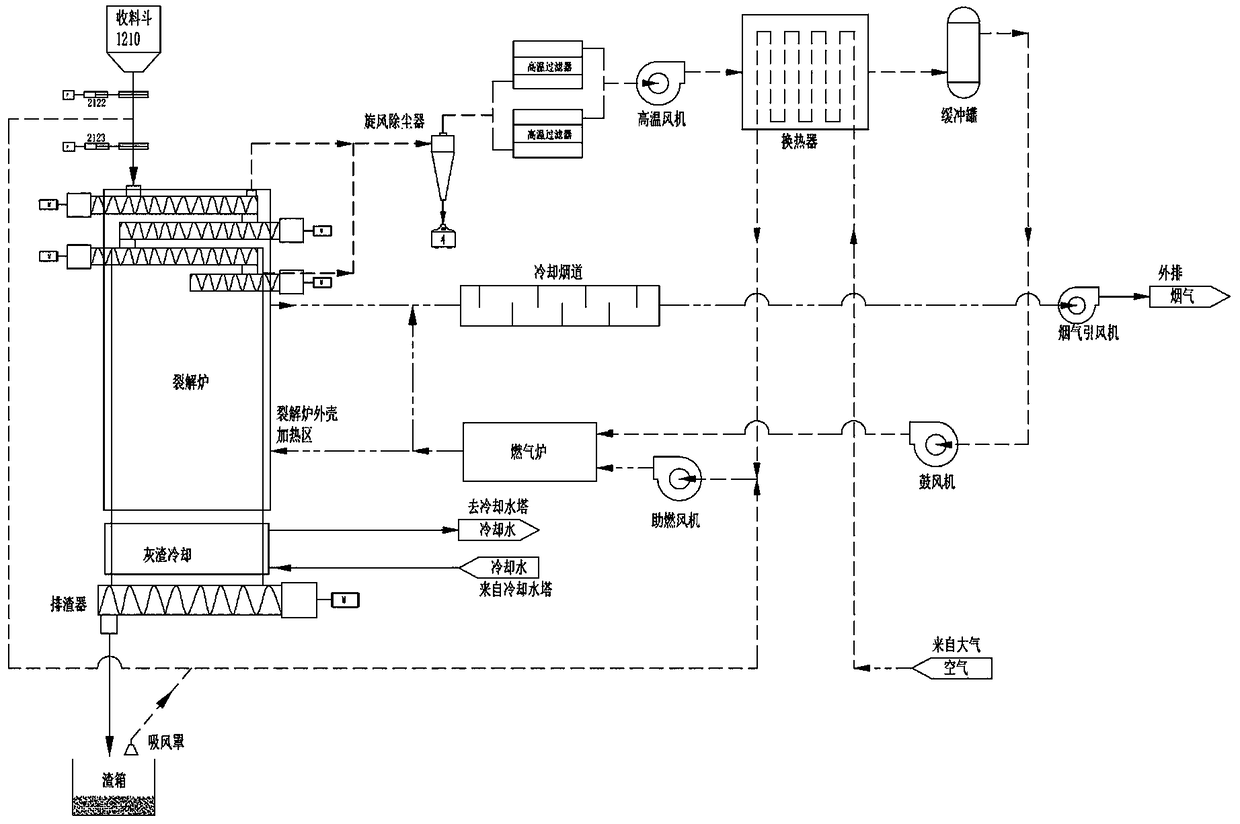

[0026] like figure 1 As shown, a kind of visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com