Solid waste recycling device

A solid waste, recycling and processing technology, applied in the removal of solid waste, grain processing, transportation and packaging, etc., can solve the problems of waste, secondary air pollution, low calorific value, etc., to reduce the amount of materials, improve the crushing effect, the effect of improving the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

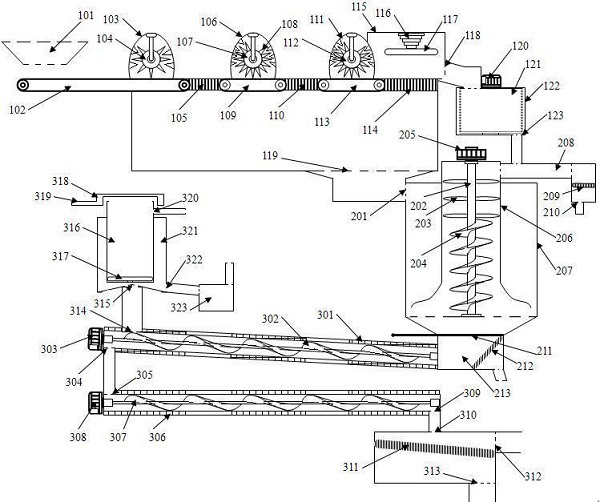

[0025] Further explanation in conjunction with accompanying drawings: Figure 1-Figure 2 The solid waste recycling and processing device of this embodiment includes a crushing and screening device, a recoil drainage device and a pyrolysis device.

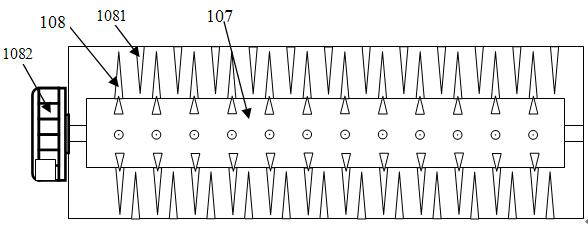

[0026] Such as figure 1 and figure 2 As shown, the crushing and screening device includes a conveying and screening part, a first crushing part, a second crushing part, a third crushing part, an extruding part and a hard object separating part; the conveying and screening part includes solid waste Inlet bin 101, first conveyor belt 102, first screening plate 105, second conveyor belt 109, second screening plate 110, third conveyor belt 113, third screening plate 114 and particle temporary storage box ( figure 1 All the conveyor belts and the lower chamber of the screening plate); the first crushing component includes the first crushing shaft 104, the first crushing inner cone, the first crushing outer cone, the first crushing dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com