Household waste pyrolysis treatment equipment

A technology for domestic waste and treatment equipment, which is applied in the field of domestic waste pyrolysis treatment equipment, and can solve problems such as smoke pollution and low efficiency of domestic waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

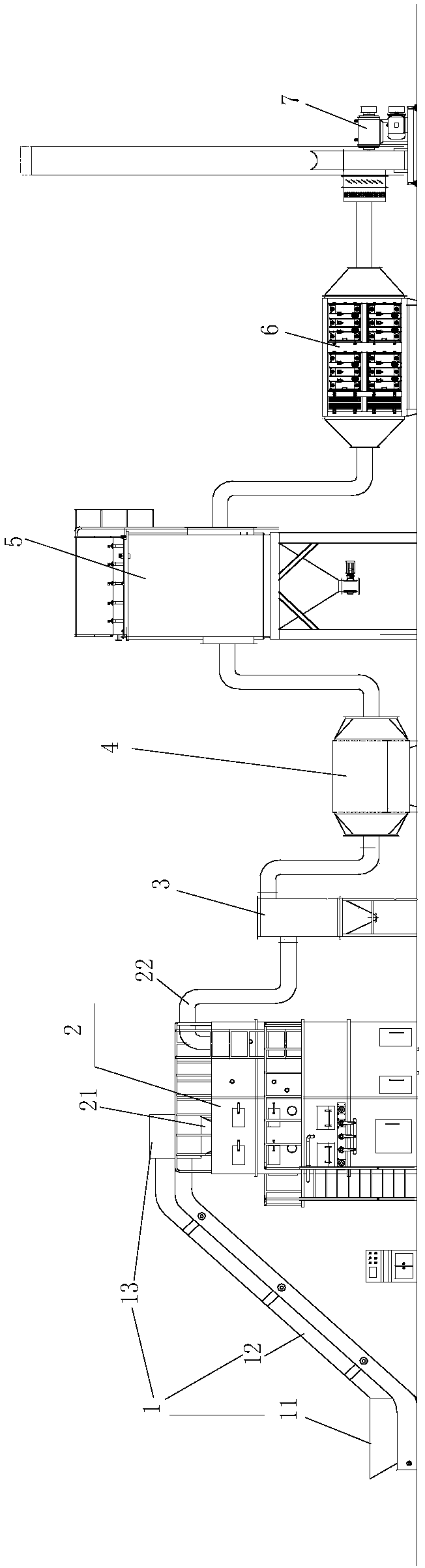

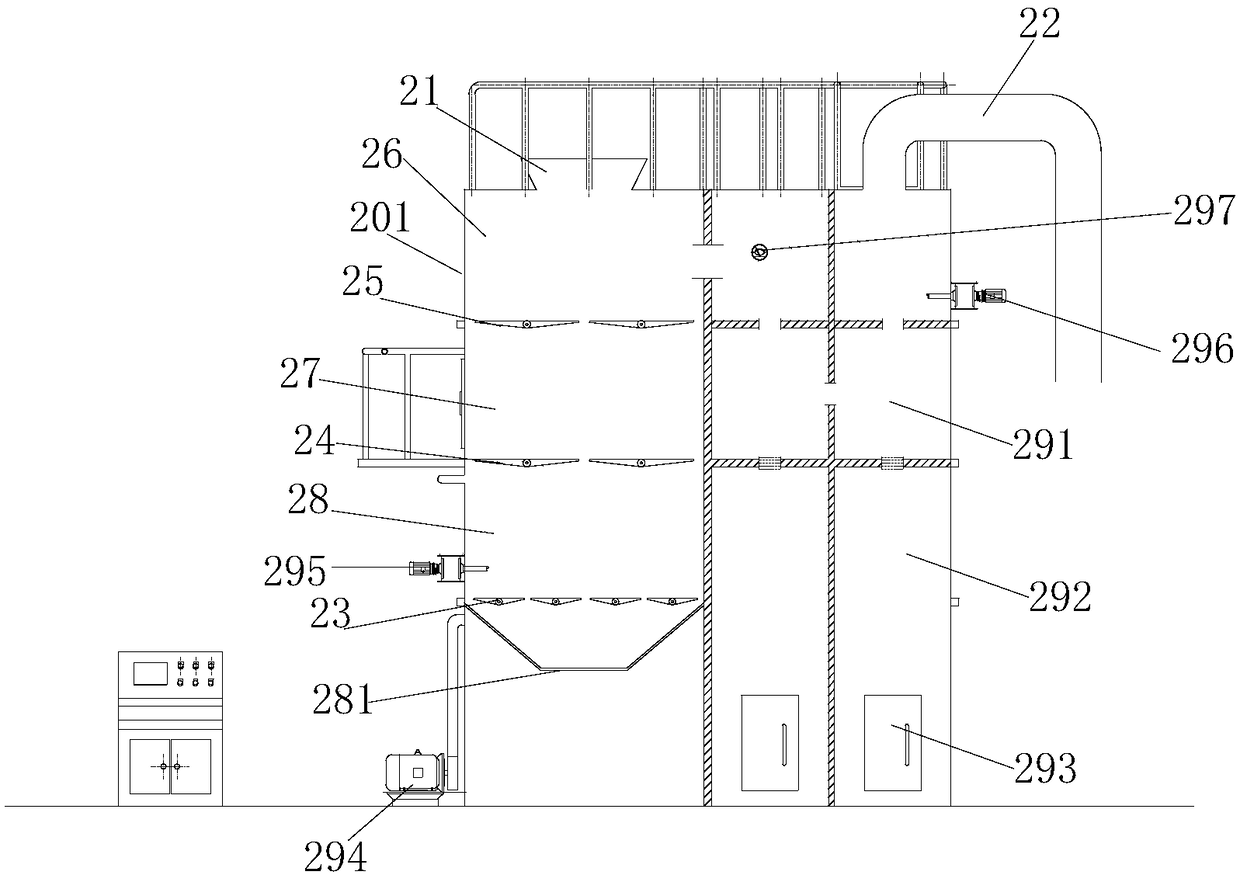

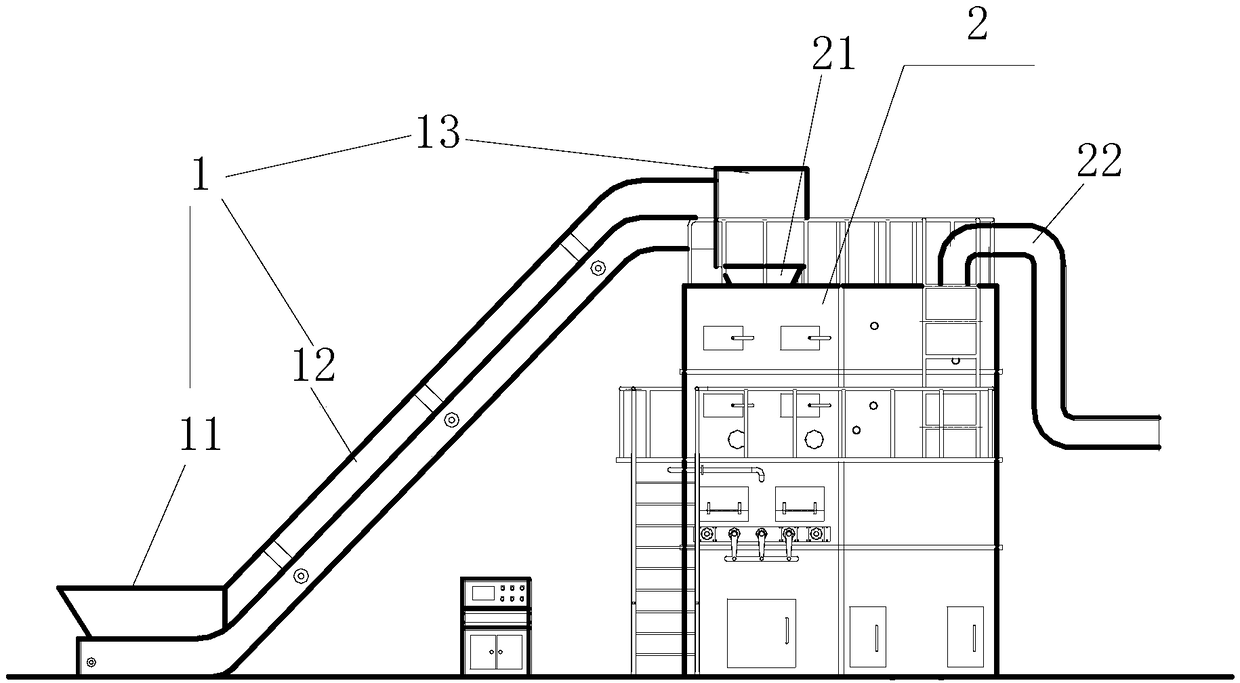

[0024] Such as figure 1 and image 3 As shown, the present invention provides a domestic garbage pyrolysis treatment equipment, said equipment includes an automatic feeder 1, a garbage pyrolysis furnace 2, a ceramic cyclone multi-tube dust collector 3, a heat exchange condenser 4, a bag filter 5, Plasma dust remover 6 and induced draft fan 7, described automatic feeder 1 comprises loading hopper 11, the conveyer belt 12 that is used to feed upwards obliquely and feeding pipe 13, and the bottom end of described conveyer belt 12 stretches into described feeding hopper 11 to accept the garbage in the feeding hopper 11, the top of the conveyor belt 12 extends into the feeding pipe 13 to transport domestic waste to the feeding pipe 13, and the garbage pyrolysis furnace 2 is provided with a garbage inlet at the top. Hopper 21 and flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com