Fluidized bed microwave pyrolysis rural domestic garbage device and use method thereof

A domestic waste and fluidized bed technology, which is applied in the field of fluidized bed microwave pyrolysis of rural domestic waste, can solve the problems of composting that cannot be reduced, the temperature of the incinerator is uneven, and incineration is easy to produce dust, etc., to achieve shortening Pyrolysis time, complete pyrolysis, and the effect of improving energy heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

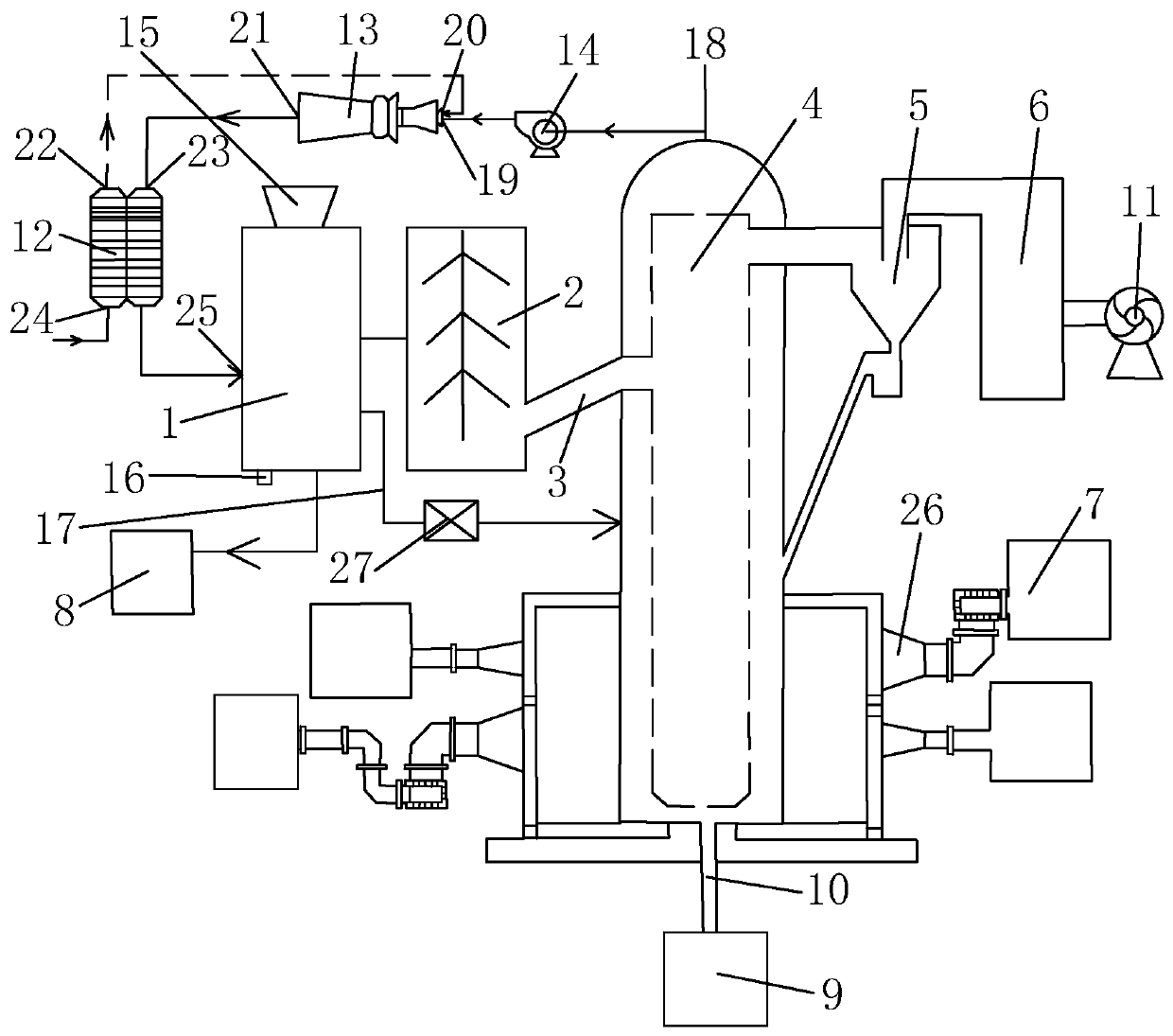

[0021] Such as figure 1 A fluidized bed microwave pyrolysis device for rural domestic garbage shown includes a drum dryer 1, a chain pulverizer 2, a screw feeder 3, and it also includes a fluidized pyrolysis chamber 4, a microwave generator 7, an air Preheater 12; tumble dryer 1 is connected with chain grinder 2; the water vapor heat containing peculiar smell produced in tumble dryer 1 can be used as the gasification agent of fluidized pyrolysis chamber 4, not only can remove peculiar smell, Also make full use of waste heat, save energy; chain pulverizer 2 is connected with the inlet of fluidized pyrolysis chamber 4 through screw feeder 3; connection; the top of the cyclone separator 5 is connected to the dust collector 6, and the solid outlet at the bottom is connected to the fluidized pyrolysis chamber 4, so that the insufficiently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com