Fluidized bed hierarchical coal pyrolysis reactor and coal pyrolysis method

A technology of pyrolysis reactor and graded coal, which is applied in the field of coal pyrolysis, can solve the problems of low methane content, high hydrogen content, unfavorable economic and safe operation of gas turbine units, etc., to achieve increased production rate, simple equipment and system , the effect of strong heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is a most preferred embodiment of the present invention, which is only used as an explanation of the present invention rather than limitation.

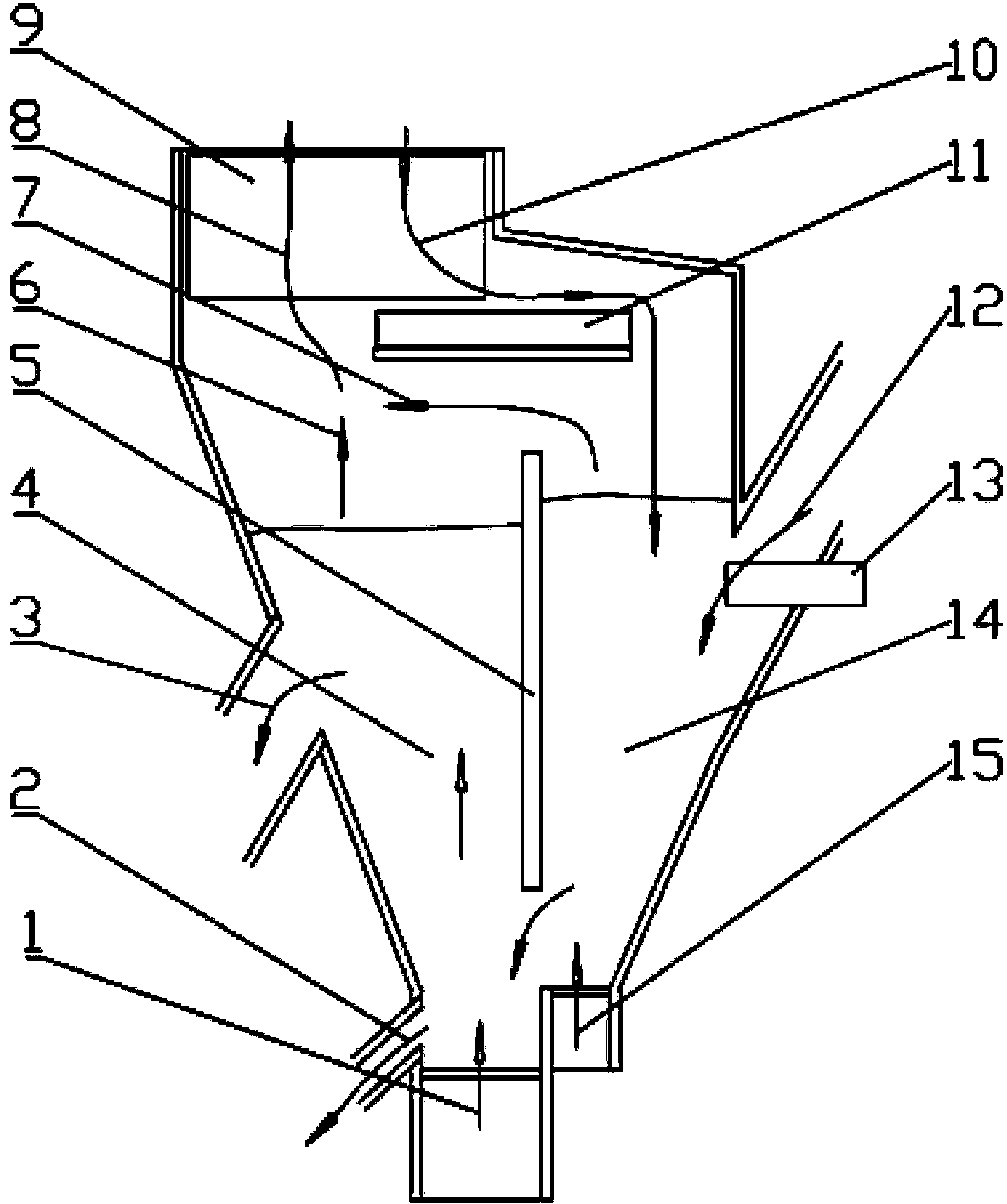

[0042] A fluidized bed reactor for coal pyrolysis includes a pyrolysis chamber composed of a low-temperature pyrolysis chamber 14 and a high-temperature pyrolysis chamber 4, a partition wall 5, a pyrolysis gas waste heat recovery device 9, a coal delivery device 11, a large Granular material outlet, high temperature pyrolysis chamber sulfide gas inlet, mixed material outlet, ash conveying device 13.

[0043] Wherein, the low-temperature pyrolysis chamber 14 and the high-temperature pyrolysis chamber 4 are separated by the partition wall 5, and the low-temperature pyrolysis chamber 14 and the high-temperature pyrolysis chamber 4 are connected at the top and the bottom of the partition wall 5 respectively, and the height of the partition wall 5 is high. At the height of the dense phase region of the two pyrolysis ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com