Piezoelectrically actuated micro-mixer, manufacturing method and control method of piezoelectrically actuated micro-mixer

A micro-mixer, piezoelectric drive technology, applied in chemical instruments and methods, pump control, mixers, etc., can solve the problems of difficult integration and miniaturization, difficult processing, poor mixing controllability, etc., and achieve mixing time. The effect of short mixing distance, simple structure and manufacturing process, and high feature size compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

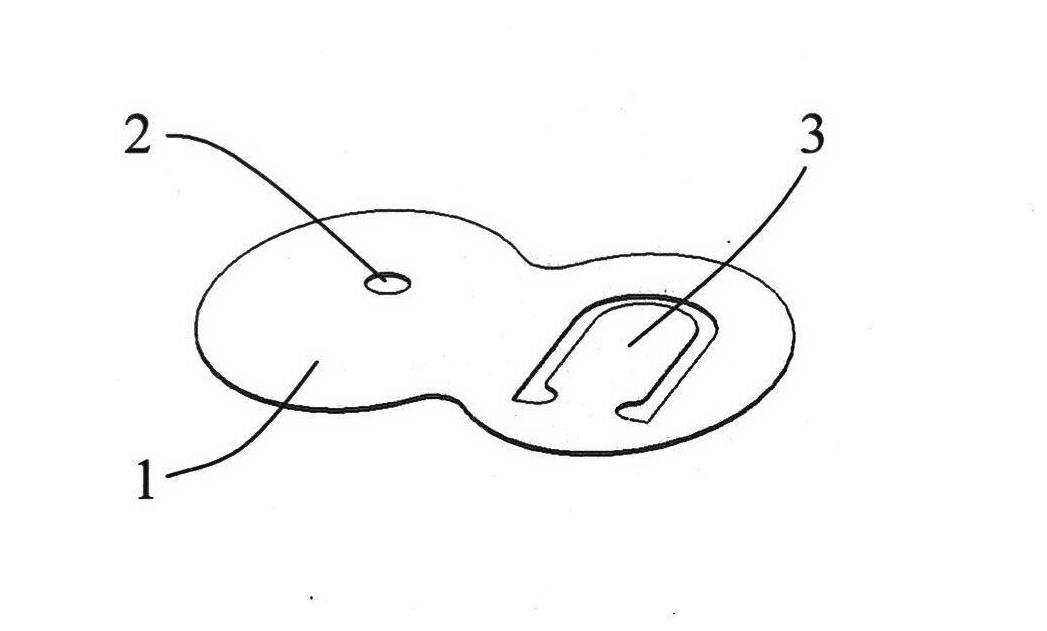

[0042] Example 1 Micro-mixer driven by a single-cavity single-oscillator piezoelectric pump

[0043] refer to figure 1, the one-way valve 3 with a cantilever beam structure and the middle access hole 2 are combined on the same substrate 1 to form an inverted "8"-shaped one-way valve plate. Check valve function for directional outflow. The variable stiffness design of the cantilever beam type one-way valve plate is realized by changing the thickness of the whole valve plate or the length of the cantilever of the valve, so as to improve the high-frequency response characteristics and outflow efficiency of the one-way valve. Among them, the inlet valve stiffness is lower than the outlet valve stiffness.

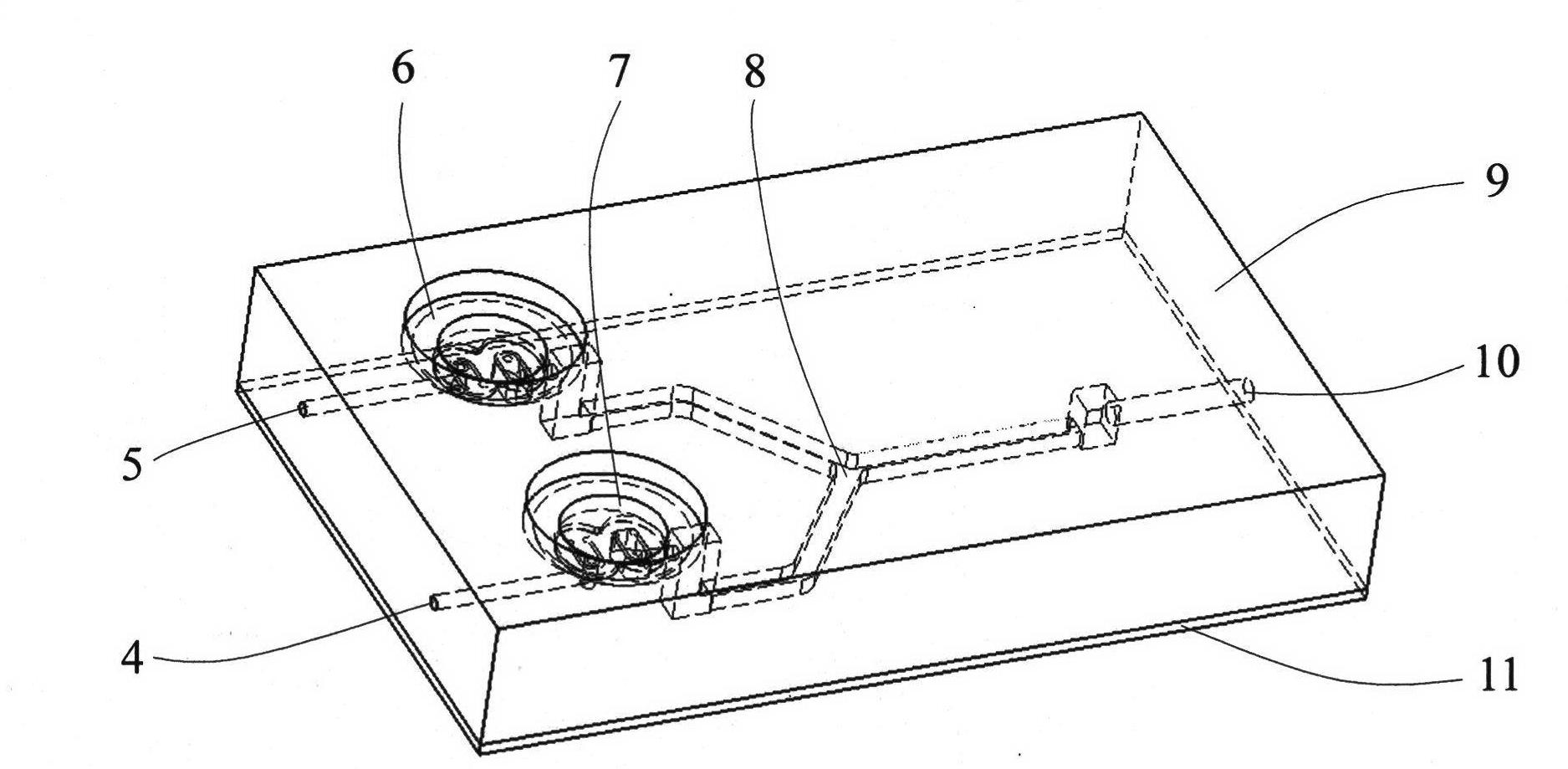

[0044] refer to figure 2 The PDMS substrate 9 integrates the piezoelectric pumps 6 and 7 and the micro-mixing channel 8, which includes two inlets 4, 5 and a mixing outlet 10. The substrate 9 is packaged with the glass bottom plate 11 to form the mixing channel 8.

[0045] ...

Embodiment 2

[0047] Example 2 A micro-mixer driven by a dual-cavity dual-oscillator serial piezoelectric pump

[0048] refer to Figure 5 , PDMS substrate 42 integrates two sets of piezoelectric pumps 39 and 40 and micro-mixing channel 41, which includes two inlets 37, 38 and mixing outlet 43, substrate 42 is packaged with glass bottom plate 44 to form mixing channel 41. Among them, each group of piezoelectric pumps adopts a double-cavity double-oscillator series structure.

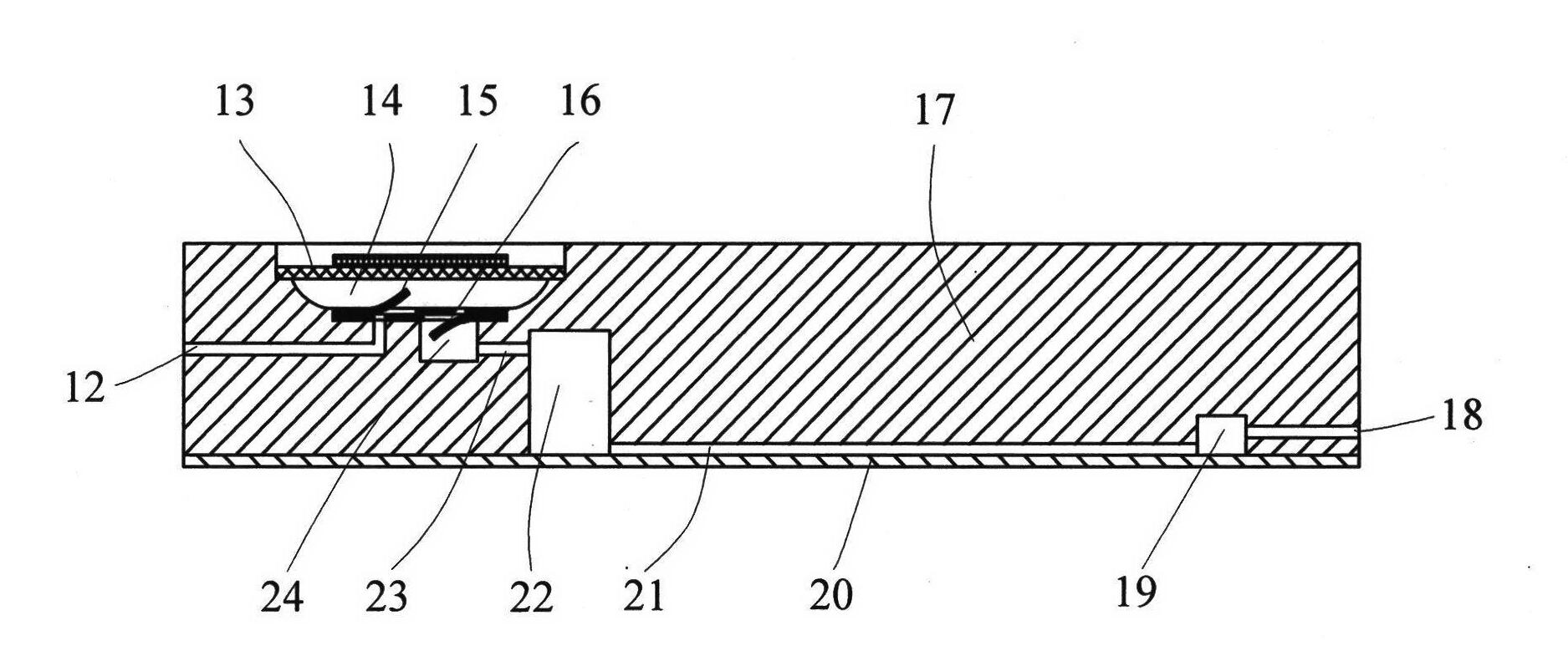

[0049] refer to Figure 6 , the working principle of each group of piezoelectric pumps and micro-mixers in Example 2 is: the piezoelectric vibrator 58 and the PDMS substrate 50 form an inlet cavity 61, the piezoelectric vibrator 46 and the PDMS substrate 50 form a series cavity 47, and the two cavities pass through The intermediate pipes 59 are connected in series. The one-way valve plate 60 is separately assembled on the PDMS substrate to form the inlet cantilever beam type one-way valve, and the middle valve plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com