Controllable fast-heating up thermobalance reacting furnace

A balance and warming technology, which is applied in the field of electric heating experimental equipment, can solve the problems of complex structure, high price, and difficult processing of thermal balances, and achieve the effects of convenient online or offline analysis, high measurement accuracy, and large controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

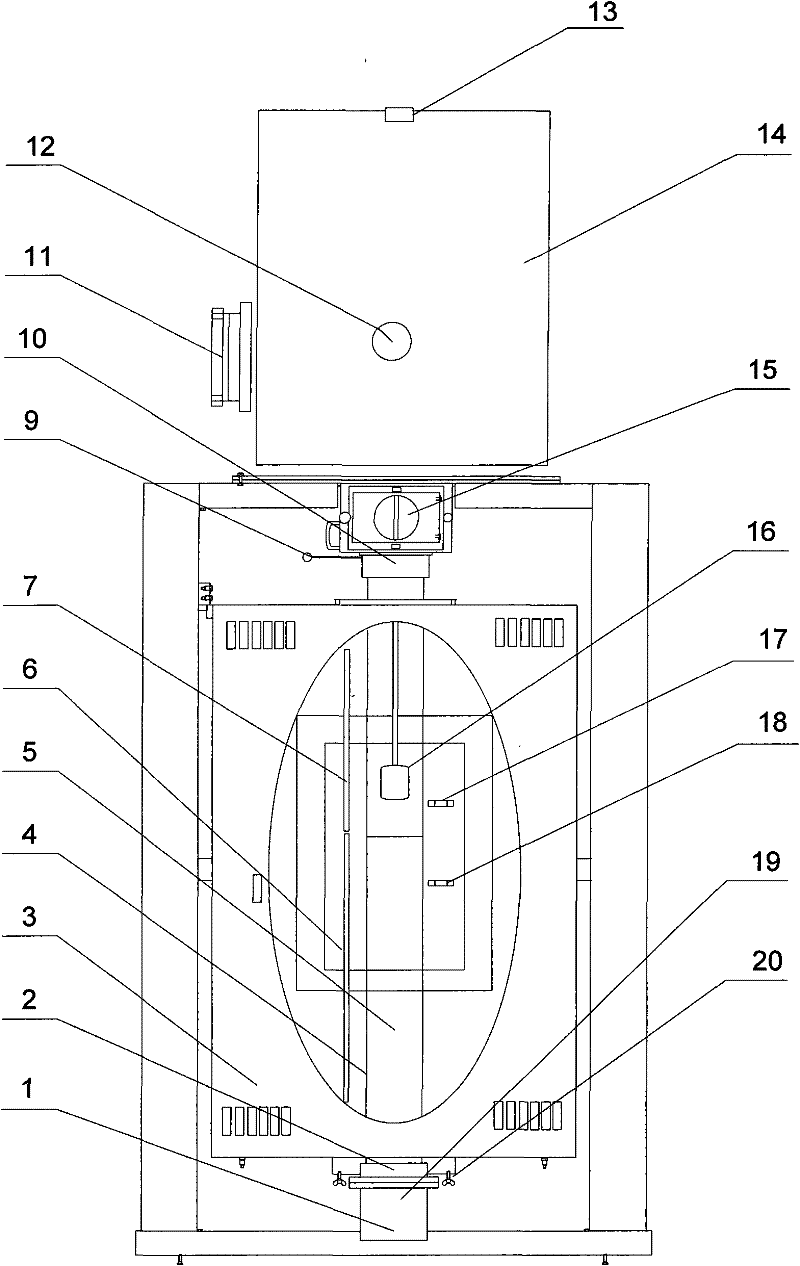

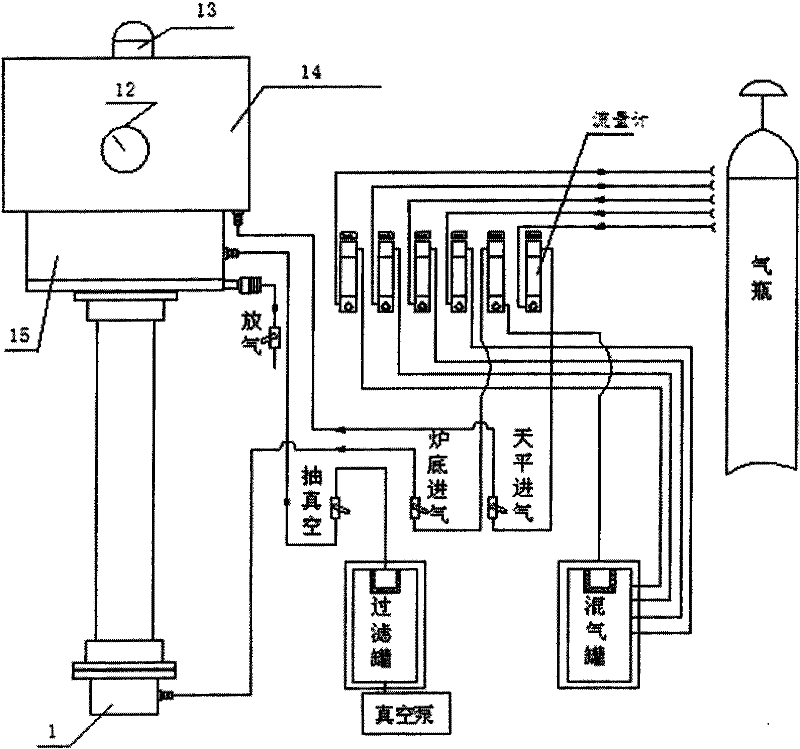

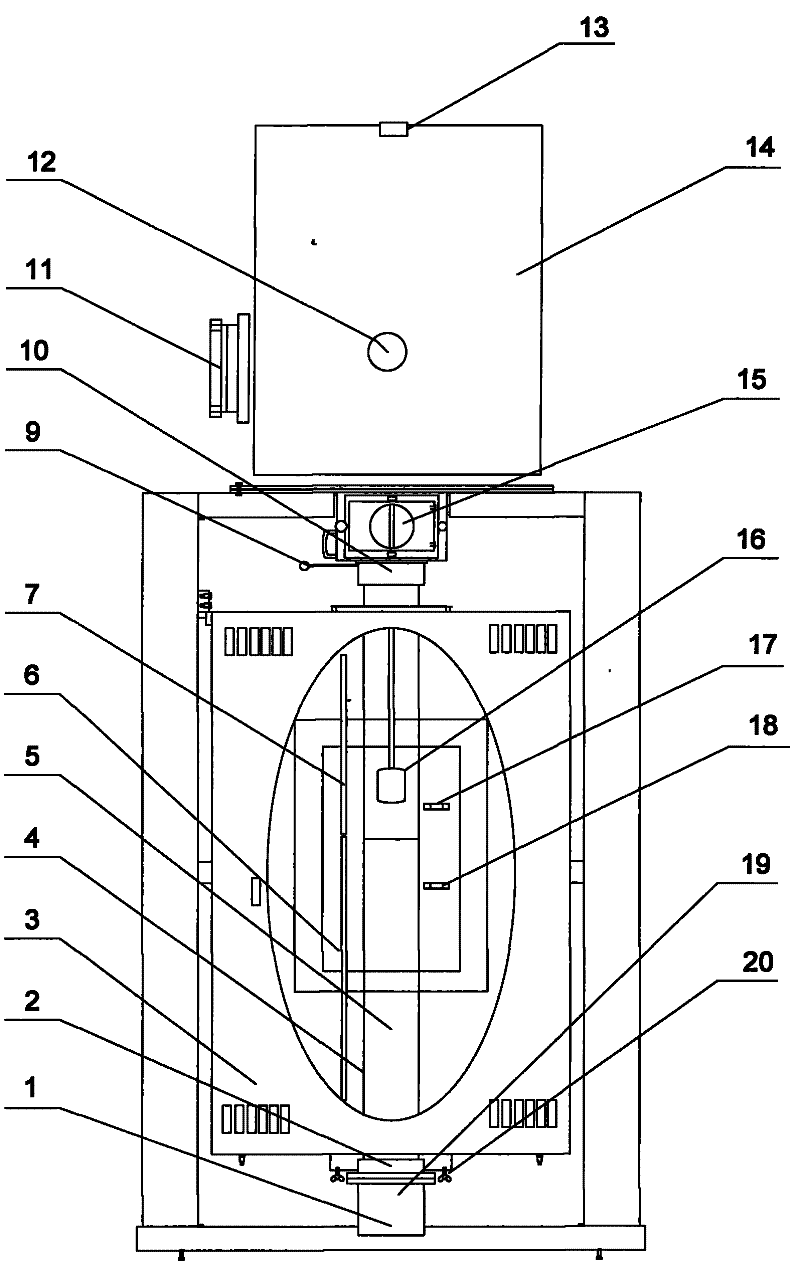

[0014] Combine below figure 1 and 2 The structure and working process of the present invention are described in further detail.

[0015] The high temperature furnace reaction device is composed of a furnace body 3, a corundum tube 4, a lower heating element 6, an upper heating element 7, an upper temperature measuring thermocouple 17 and a lower temperature measuring thermocouple 18. The high-temperature furnace reaction device adopts two-stage heating. The reaction tube is corundum tube 4, and the heating bodies 6 and 7 are silicon carbide rods. The rate controllable range is large. The heating elements 6, 7 and thermocouples 17, 18 at the upper and lower ends are respectively placed on the outer wall of the corundum tube 4, and the temperature signals measured by the thermocouples 17, 18 are collected and transmitted through the circuit control system in the electronic control device, and finally The operation interface provided by the computer control system is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com