Liquid level control method of continuous casting machine

A technology of liquid level control and liquid level controller, which is applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve problems such as crystallizer liquid level instability, and achieve the effect of increasing the controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

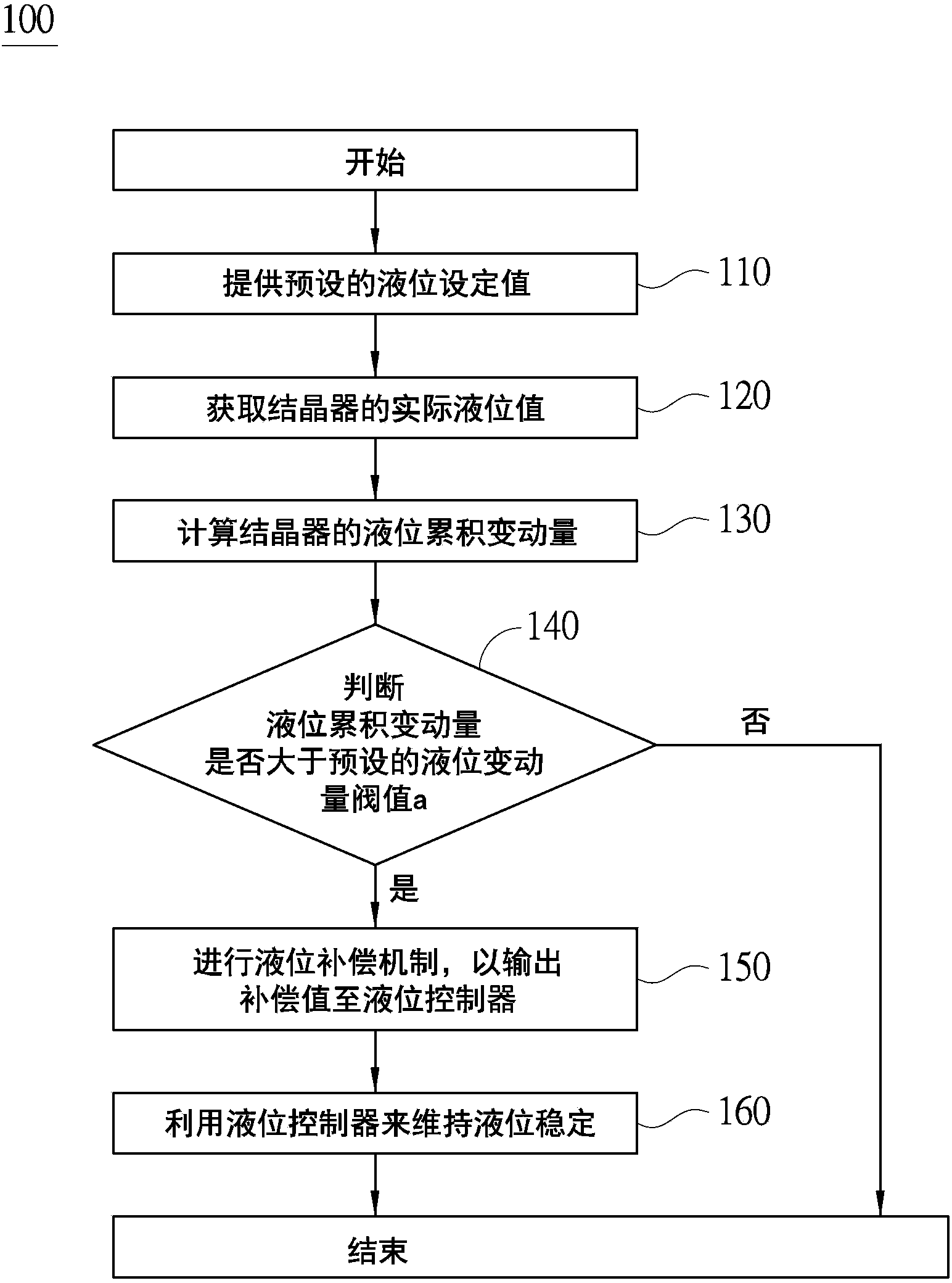

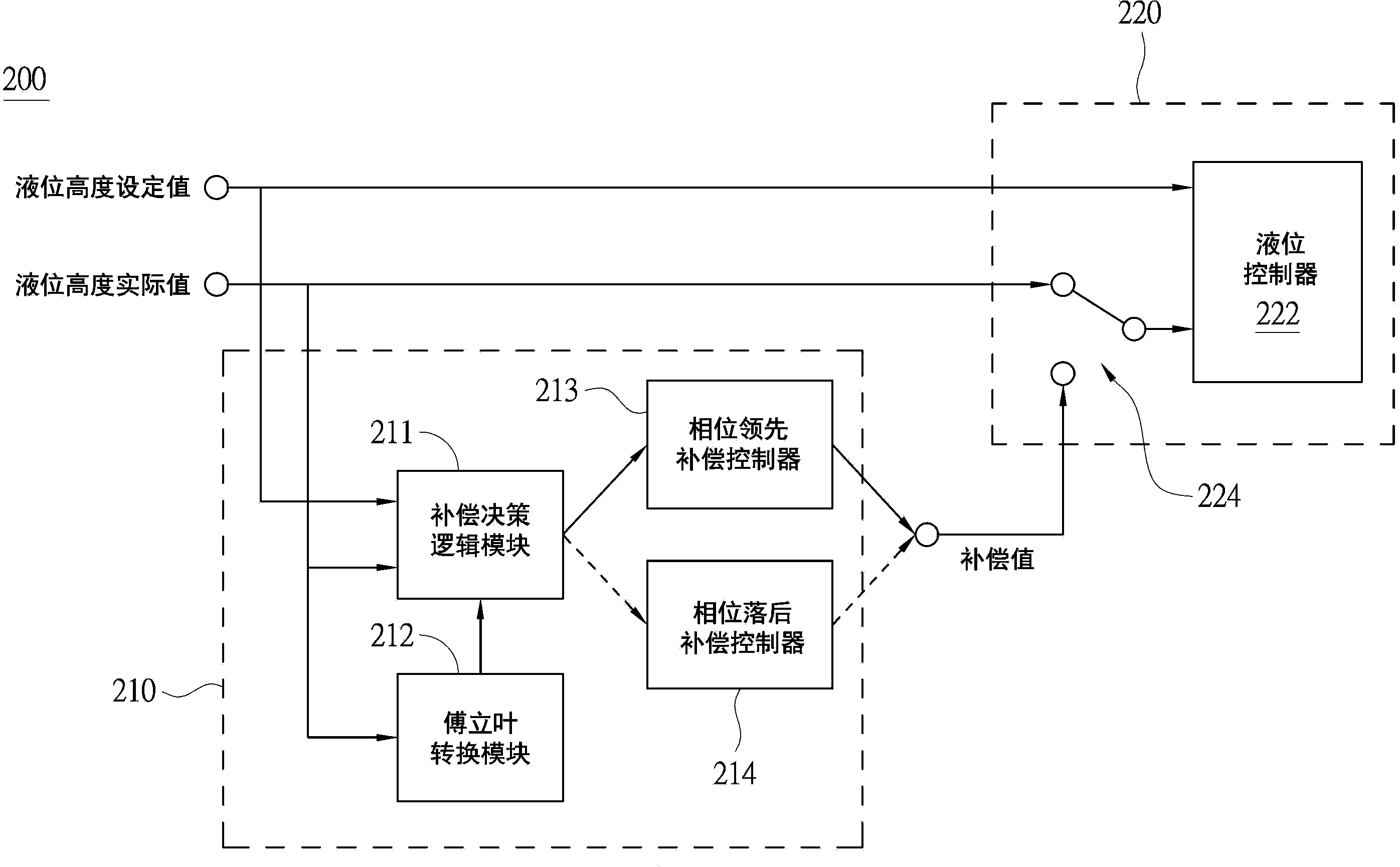

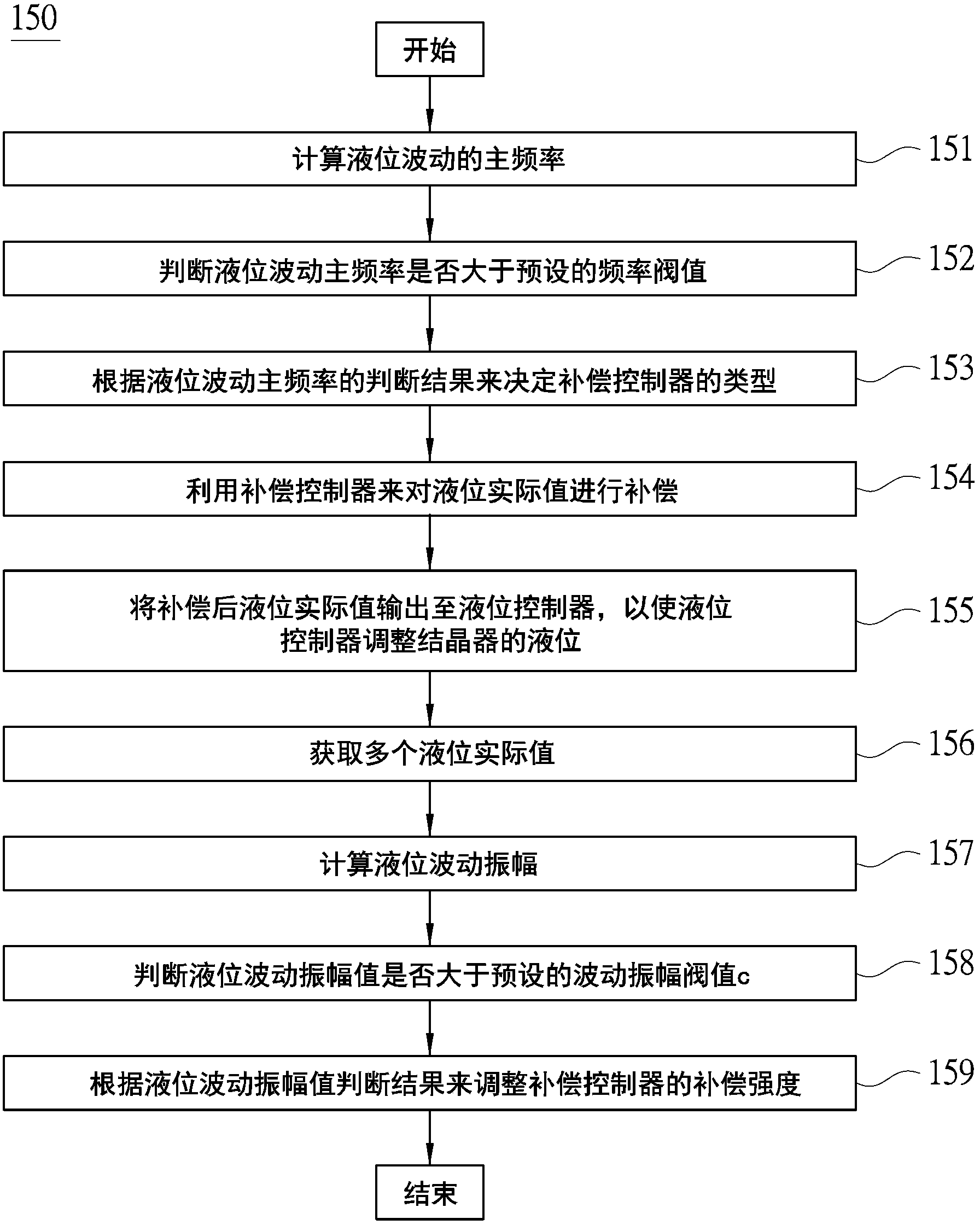

[0017] Please also refer to figure 1 and figure 2 , figure 1 It is a schematic flow chart illustrating a liquid level control method 100 for a continuous casting machine according to an embodiment of the present invention, figure 2 It is a schematic diagram illustrating a liquid level compensation system 200 of a continuous casting machine according to an embodiment of the present invention. The liquid level compensation system 200 of this embodiment uses the liquid level control method 100 to compensate for the actual value of the liquid level, so as to increase the controllable range of the continuous casting machine to the liquid level of the mold. The compensation device 210 includes a compensation decision logic module 211 , a Fourier transform (Fourier transform) module 212 , a phase lead compensation controller 213 , and a phase lag compensation controller 214 . The compensation decision logic module 211 utilizes the continuous casting machine liquid level control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com