Pressure maintaining device in rock creep impact and micro-fracture scanning experiment and experiment method

A pressure-holding device and micro-crack technology, which can be used in measuring devices, using stable tension/pressure to test material strength, and using acoustic wave emission technology for material analysis. Integrated equipment, unable to dock with rock loading experimental equipment, unable to scan and detect micro-cracks inside rocks in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

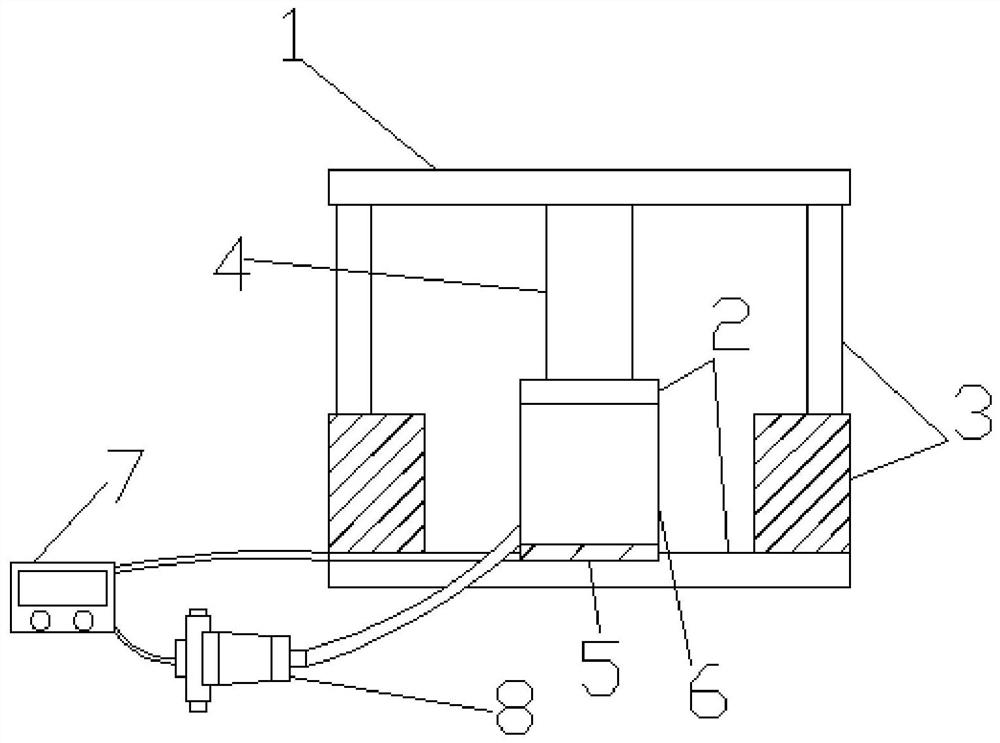

[0069] Taking a certain rock uniaxial compression creep perturbation effect mechanics experiment as an example, the experimental method of the present invention is specifically described:

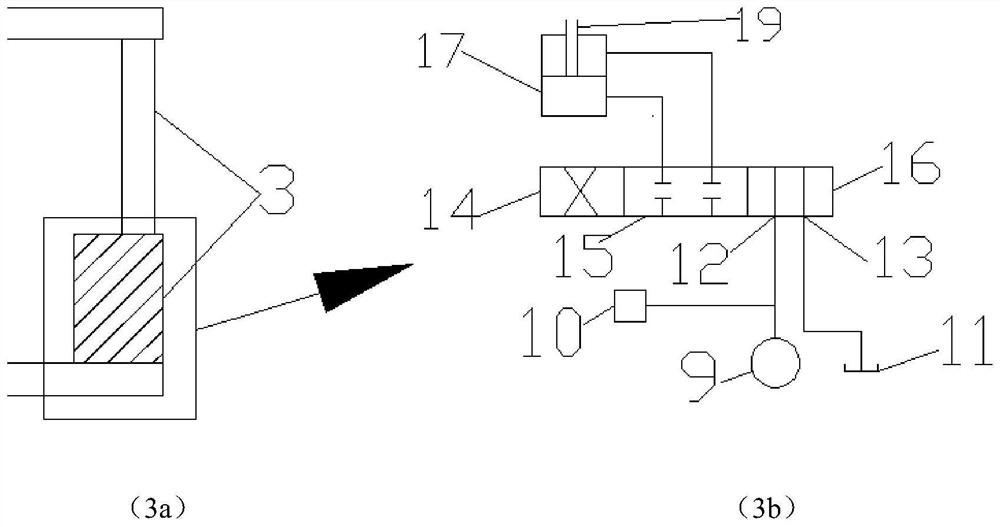

[0070]In this experiment, a total of impact disturbance experiments were carried out under three levels of static load stress. The three levels of static load stress levels were 40MPa, 60MPa and 80MPa respectively. Dynamic impact disturbance experiments were carried out under each level of static load level. After the impact was completed, the specimen was pressed Move out, use CT scanner to scan the micro-cracks inside the rock, and finally get the micro-cracks development law of the rock under the creep impact. Its specific experimental steps include:

[0071] Step 1: Before the experiment starts, first prepare a standard rock specimen, diameter×height=50mm×100mm;

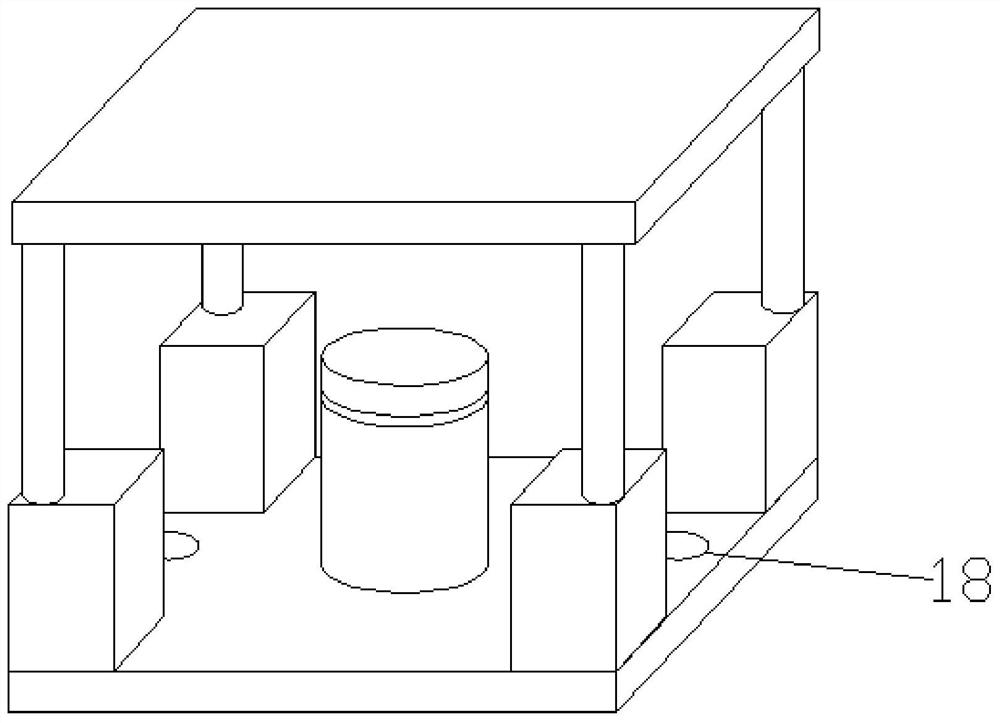

[0072] Step 2: Extend the cylindrical pressure rods of the constant pressure locking mechanism 3 at the four corners to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com