Device for live replacement of cross arm and insulator string and application method

A technology of insulator strings and live replacement, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing manpower and material resources, reducing work efficiency, and narrow operating space, so as to increase connection stability, reduce labor intensity, increase Large controllable range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

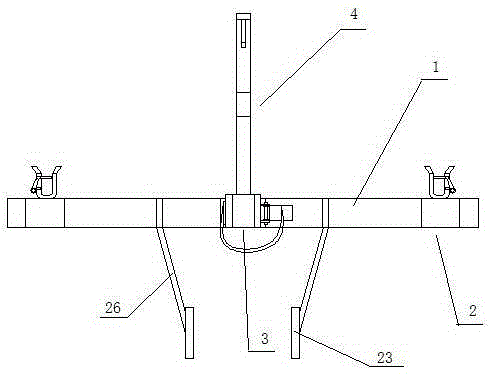

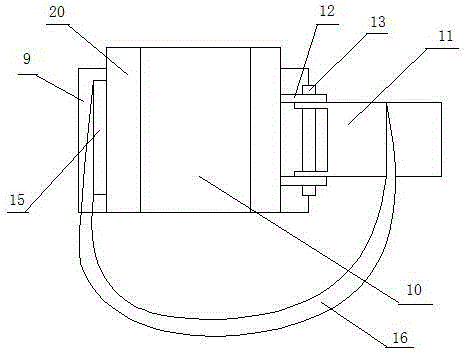

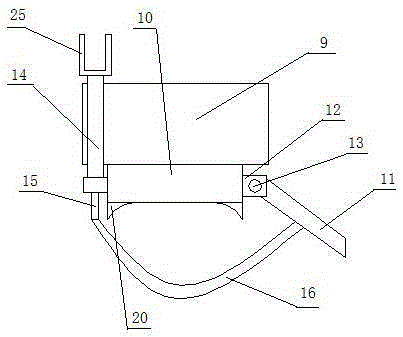

[0017] Below in conjunction with accompanying drawing, the present invention is further described:

[0018] As shown in the accompanying drawings, a device and method for replacing cross-arms and insulator strings with electricity is characterized in that an insulating cross-bar 1 is provided, and the left and right sides of the insulating cross-bar 1 are symmetrically provided with two sides of the cross-arm The wire support unit 2 of the electric wire, the front and rear sides of the middle part of the insulating cross bar 1 are respectively provided with a holding unit 3 for holding the electric pole tightly and a branch line unit 4 for lifting the electric wire on the top of the electric pole. Unit 2 is composed of a hoop-type connecting seat 5 with adjustable position, a U-shaped wire support groove 6 and a right-angled wire retaining rod 7, wherein the hoop-type connecting seat 5 is connected with the insulating cross bar 1, and the hoop-type connecting seat The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com