Fuel pre-evaporation and premix perforated pipe

A pre-evaporation and pre-mixing technology, which is applied to engine components, turbine/propulsion fuel delivery systems, charging systems, etc., can solve the problems of slow mixing speed, large size, and unsatisfactory fuel evaporation and pre-mixing effect. The effect of turbulence, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

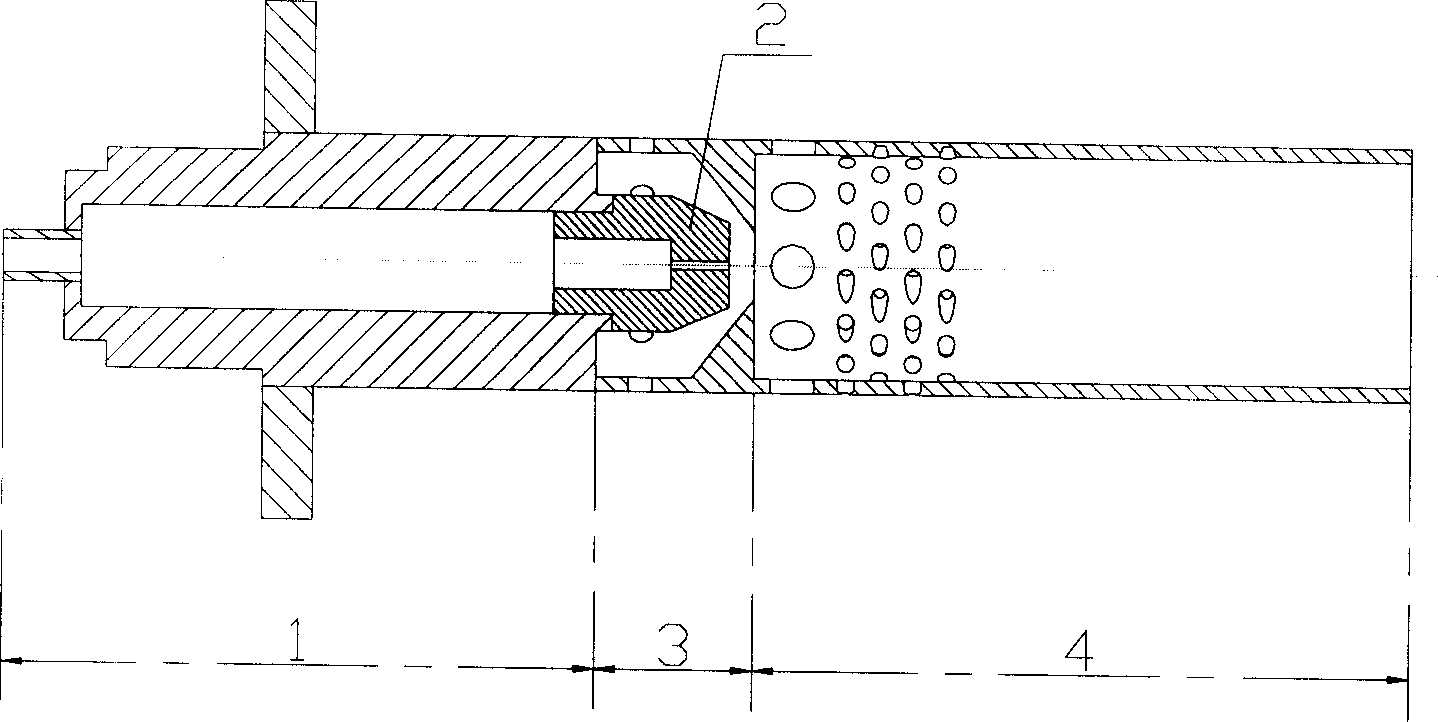

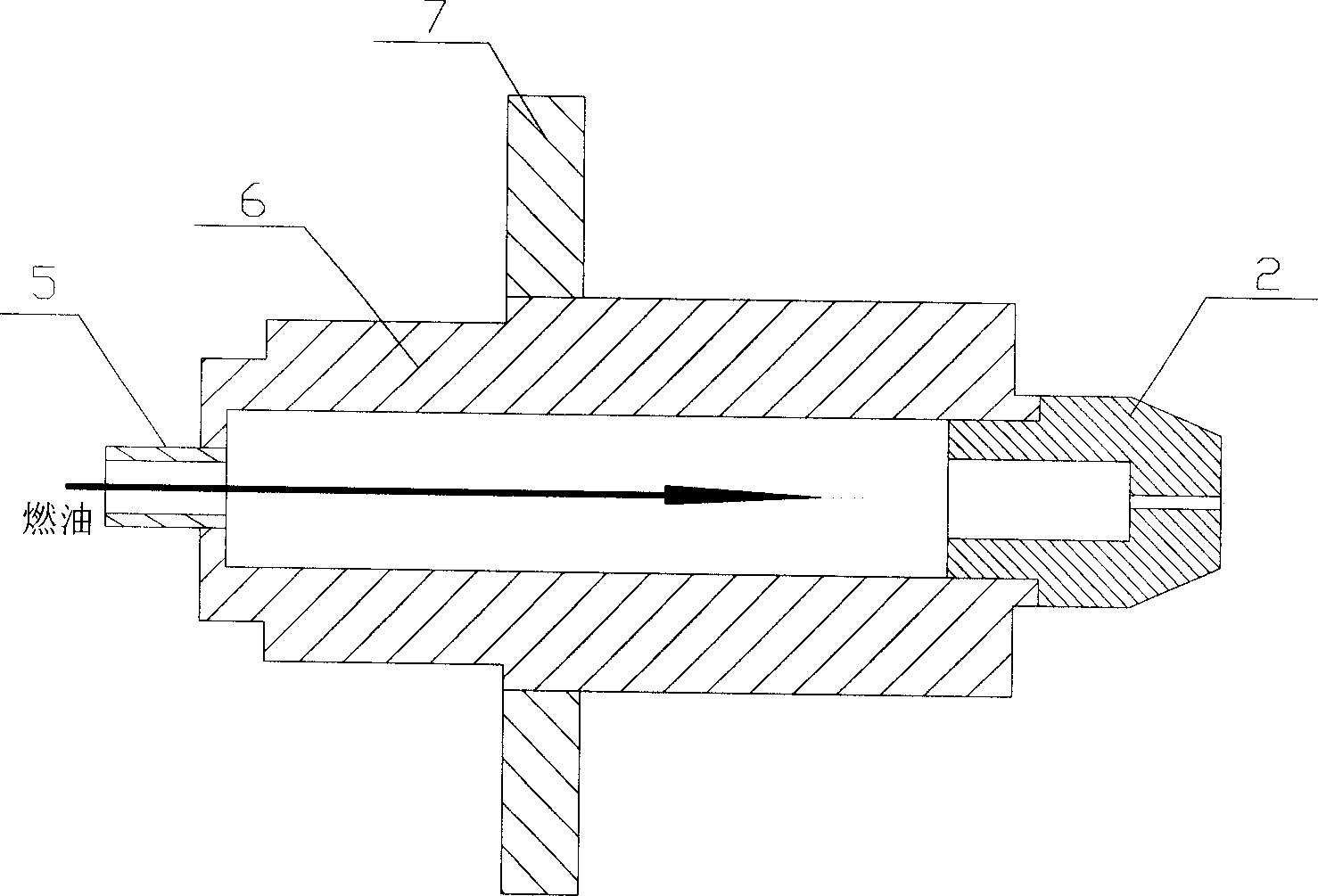

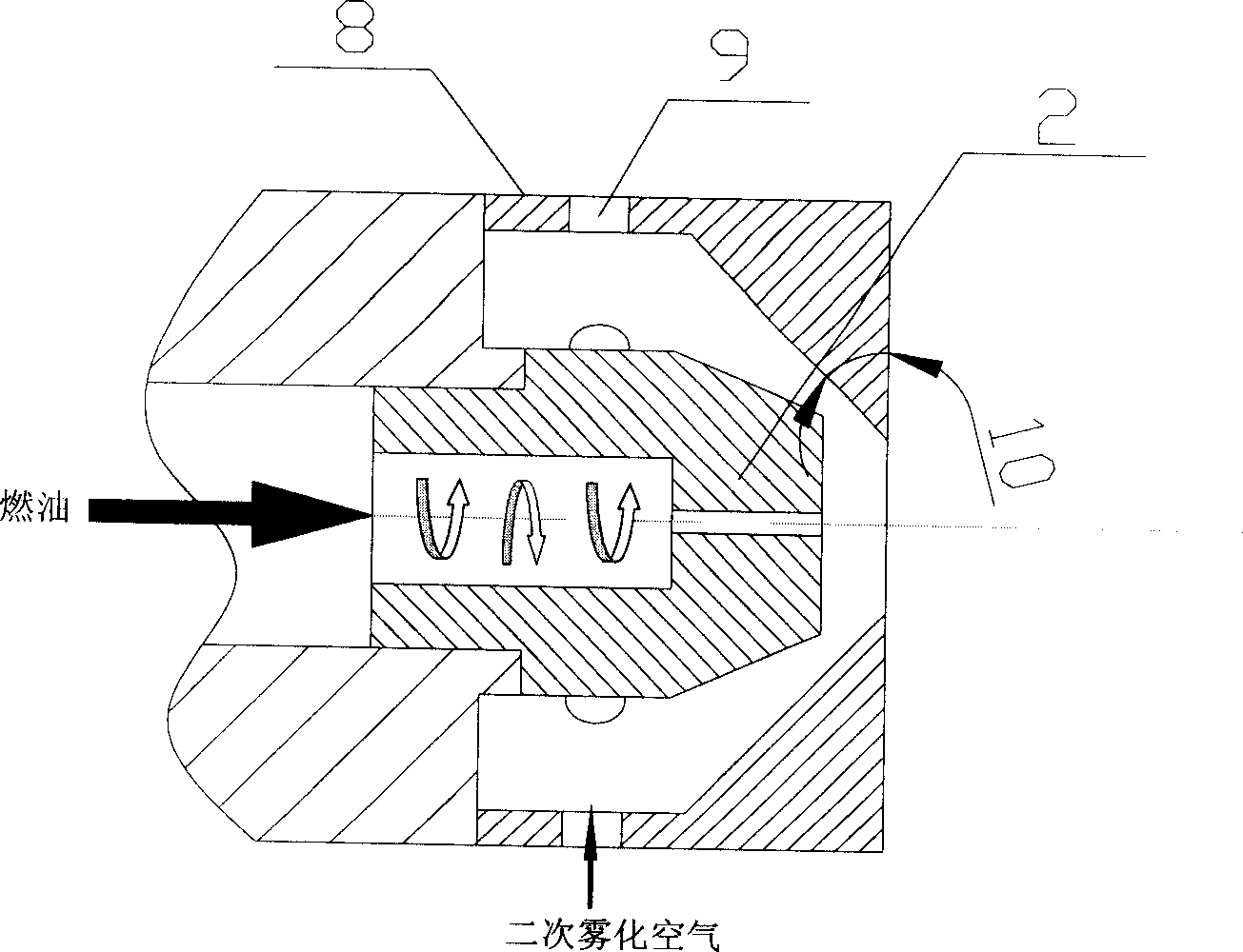

[0023] Such as figure 1 , 2 , 3, 4, the present invention consists of an oil supply part 1, a nozzle section 3 and a mixing section 3. The fuel supply part 1 includes a fuel inlet 5 and a connecting channel 6, and the connecting channel 6 is fixedly connected to external equipment through a flange 7; the outlet of the connecting channel 6 is connected to the fuel nozzle 2 of the nozzle section 3, wherein the fuel nozzle 2 adopts a centrifugal nozzle, and the There are 6-12 straight holes 9 with a diameter of 2.2 to 3.2 mm on the pipe wall 8 of the nozzle section 3, the outlet 10 of the nozzle section 3 is in a contracted shape, and a row of 4 to 10 holes is punched on the pipe wall 11 of the mixing section 4. a straight hole with a diameter of 3.0 to 5.4mm and 50 to 100 4-8 rows of oblique holes 13 with a diameter of 2mm, wherein the angle of the oblique holes 13 is 25° to 50°.

[0024] Table 1 shows the specific dimensions in the above figures

[0025] specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com