Double helix mixer

A technology of double-helix mixing and mixing cylinders, which is applied to mixers, mixers with rotating containers, mixing methods, etc., can solve the problems of high manufacturing and maintenance costs, high operating costs, and complex structures, and achieve low manufacturing costs. The effect of low operating cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

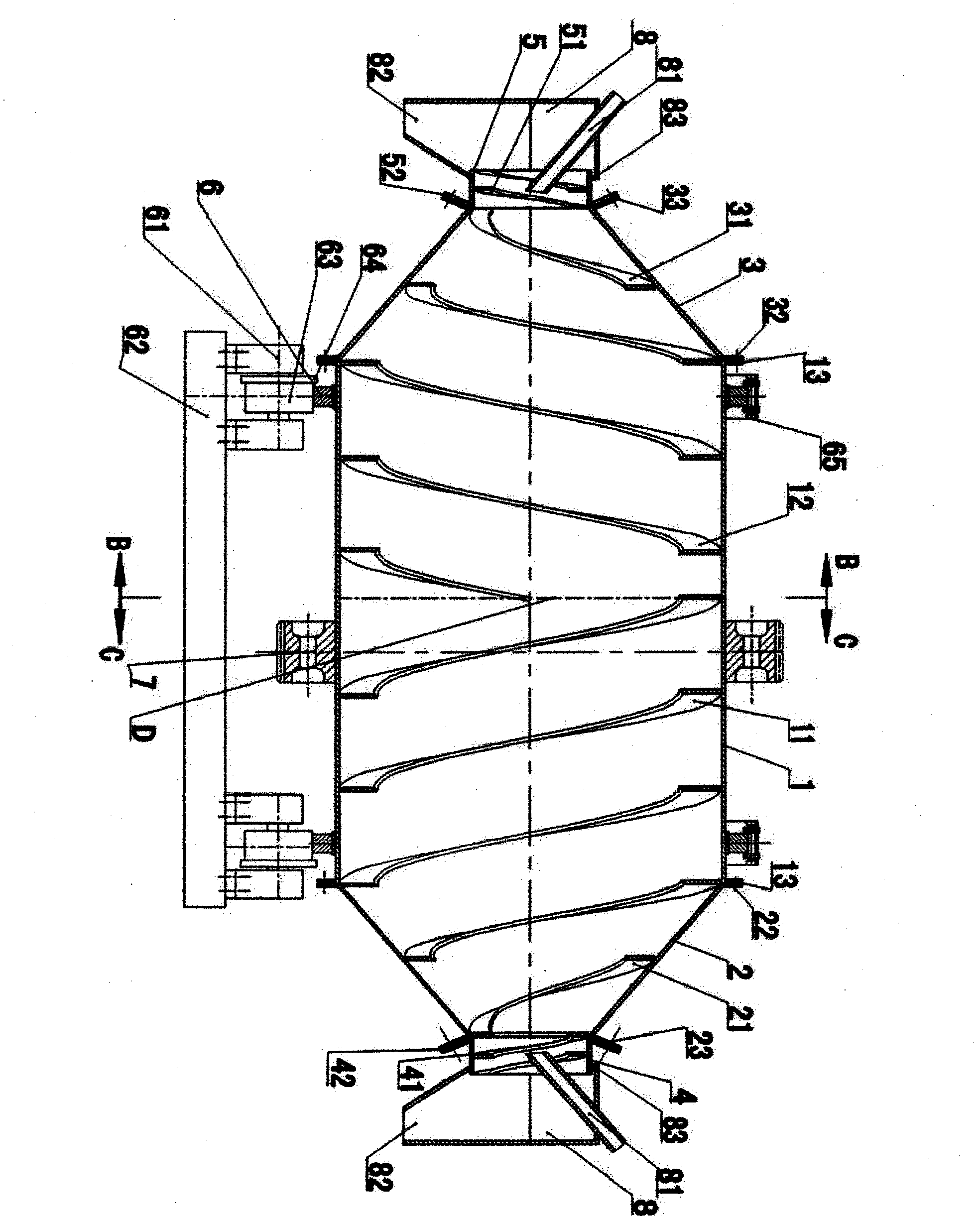

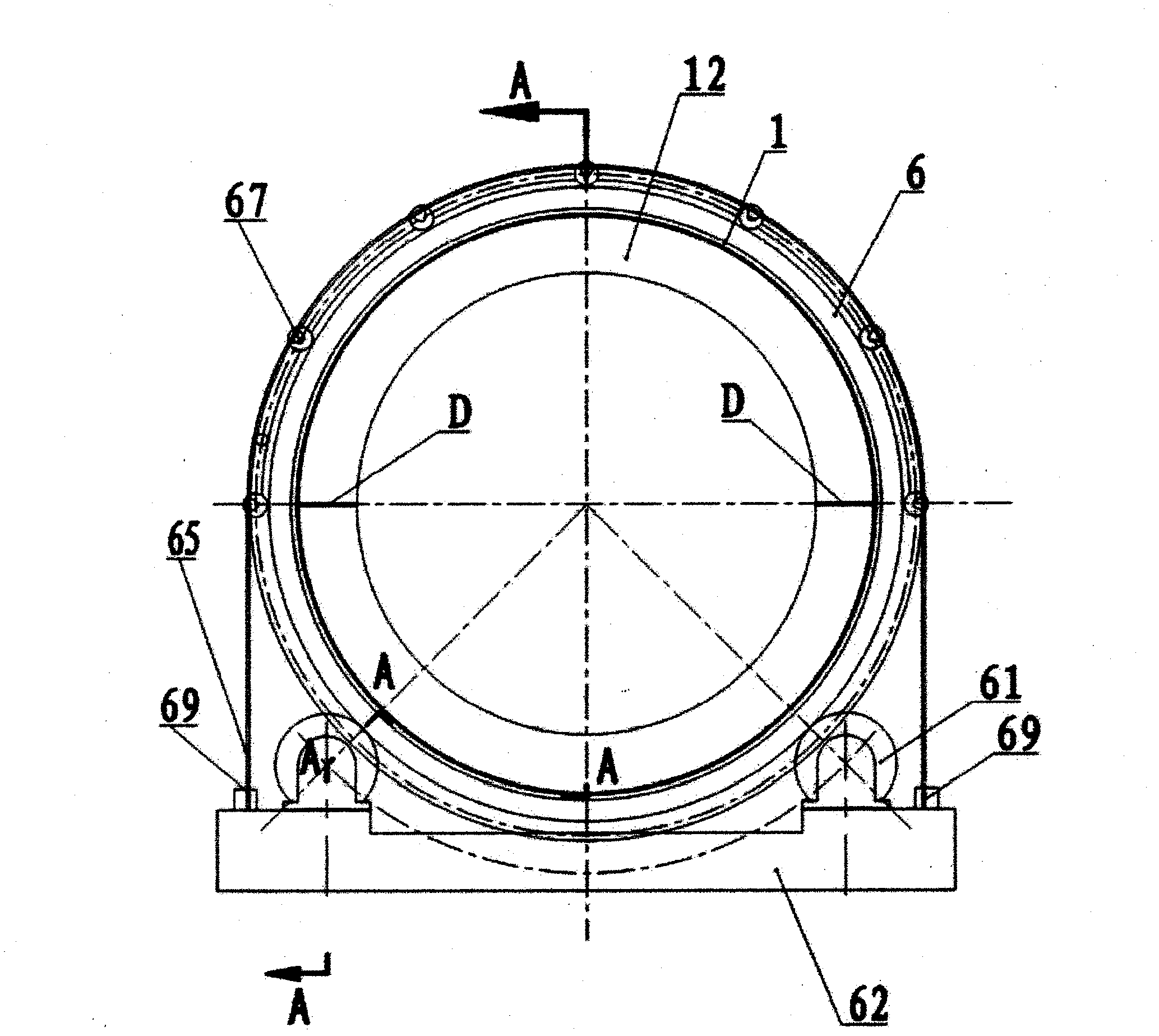

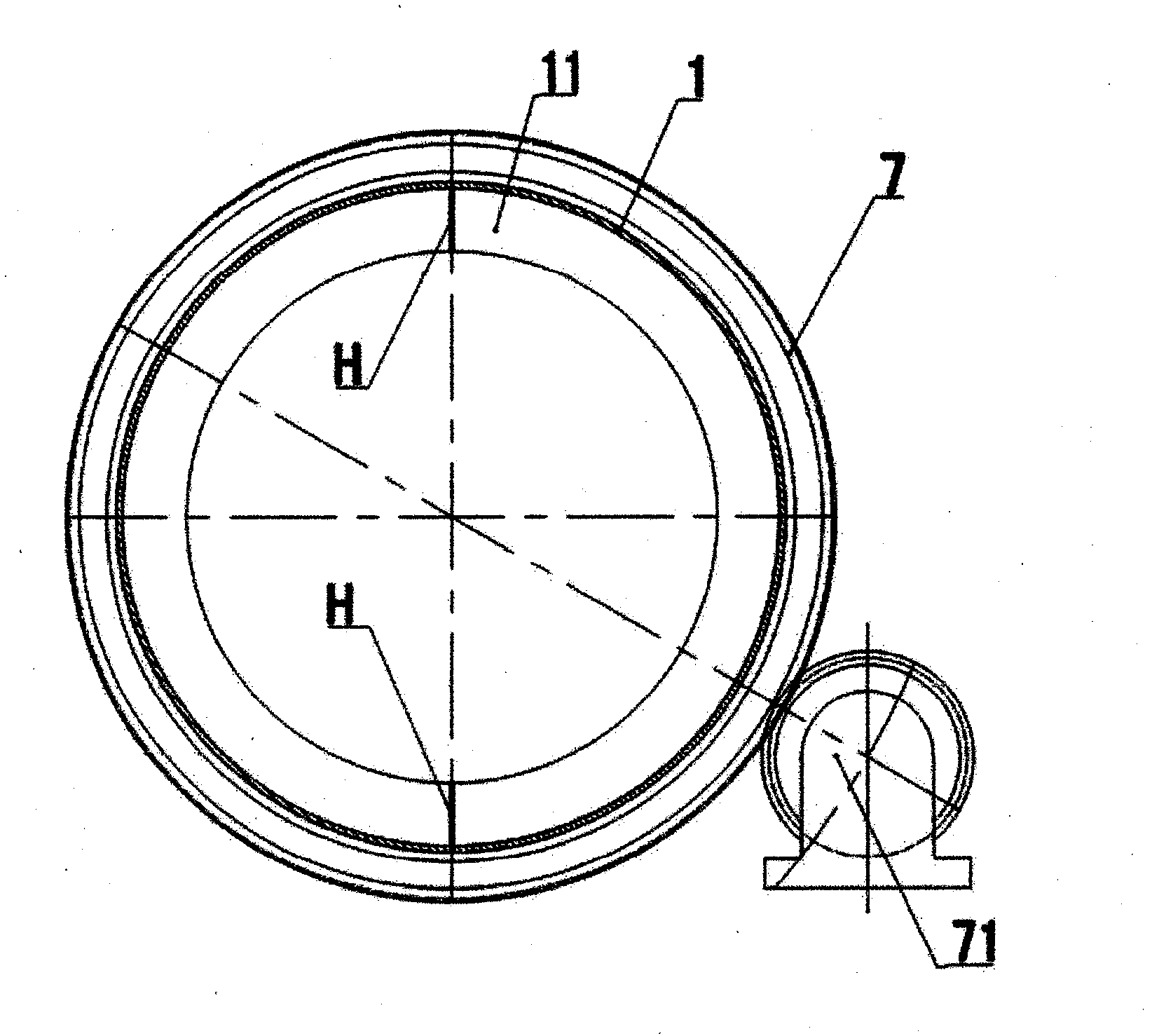

[0031] refer to figure 1 , The double-screw mixer of the present invention is composed of a cylinder part, an inlet and outlet part, a support part and a transmission part. The cylinder consists of a mixing cylinder 1, a left-handed helical blade 11, a right-handed helical blade 12, a cylinder connecting flange 13, a conical conveying cylinder-2, a left-handed conical helical blade 21, and a large end connecting flange-22 , the small end is connected to the flange 1 23, the conical conveying cylinder 2 3, the right-handed conical spiral blade 31, the large end is connected to the flange 2 32, the small end is connected to the flange 2 33, the feeding and discharging conveying cylinder 1 4, left-handed Spiral blade 41, connecting flange 1 42, feeding and discharging material conveying cylinder 2 5, right-handed spiral blade 51, connecting flange 2 52 is composed. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com