Dispersion method for positive electrode slurry of lithium ion battery

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unstable energy, long stirring time, secondary agglomeration, etc., saving stirring time, improving production efficiency, mixing The effect of short feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add PVDF (Solvay 5130) binder into the glue tank, prepare according to the solid content of the binder at 5%, start the dispersion at 1500r / min, and stir for 45 minutes;

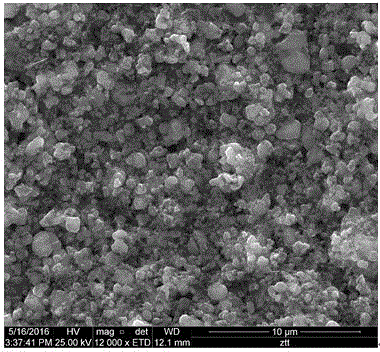

[0025] (2) Add glue, conductive carbon black, polyethylene glycol and N-methylpyrrolidone into the mixing tank, the amount of conductive agent is 4%, the amount of binder is 2.5%, and the amount of polyethylene glycol is 0.2%, control the solid content of the dispersion at 13.5%, under the condition of vacuum -85Kpa at a revolution speed of 35r / min, disperse at 1500r / min, stir for 90 minutes to obtain a pre-dispersion;

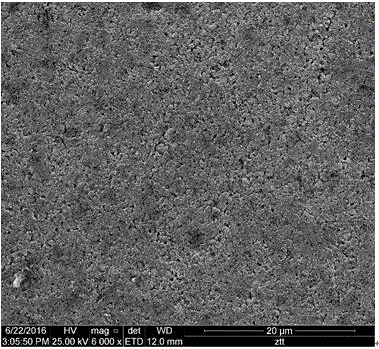

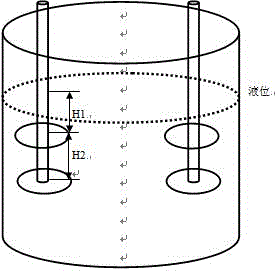

[0026] (3) Add the positive electrode active material in two times, the first time is pre-mixing, under the condition of vacuum -85Kpa, the revolution speed is 25r / min, the dispersion is 1000r / min, stirring for 10 minutes, and the second time is high-speed dispersion mixing , the solid content of the dispersion liquid is controlled at 62%, and the liquid level requirement of the d...

Embodiment 2

[0029] (1) Add PVDF (Solvay 5130) binder into the glue tank, prepare according to the solid content of the binder at 7%, start the dispersion at 1500r / min, and stir for 45 minutes;

[0030] (2) Add glue, conductive carbon black, polyethylene glycol and N-methylpyrrolidone into the mixing tank, the amount of conductive agent is 3.5%, the amount of binder is 3%, and the amount of polyethylene glycol is 0.2%, control the solid content of the dispersion at 16%, under the condition of vacuum -85Kpa, at a revolution speed of 30r / min, disperse at 1500r / min, and stir for 120 minutes to obtain a pre-dispersion;

[0031] (3) Add the positive electrode active material in two times, the first time is pre-mixing, under the condition of vacuum -85Kpa at a revolution speed of 30r / min, disperse at 1200r / min, stir for 20 minutes, after the second time, it is high-speed dispersion mixing , the solid content of the dispersion liquid is controlled at 64%, and the liquid level requirement of the d...

Embodiment 3

[0034] (1) Add PVDF (Solvay 5130) binder into the glue tank, prepare according to the solid content of the binder at 4.5%, start the dispersion at 1500r / min, and stir for 45 minutes;

[0035] (2) Add glue, conductive carbon black, polyethylene glycol and N-methylpyrrolidone into the mixing tank, the amount of conductive agent is 4%, the amount of binder is 3%, and the amount of polyethylene glycol is 0.2%, control the solid content of the dispersion at 15.5%, under the condition of vacuum -85Kpa at a revolution speed of 35r / min, disperse at 1600r / min, and stir for 70 minutes to obtain a pre-dispersion;

[0036] (3) Add the positive electrode active material in two times. The first time is pre-mixing. Under vacuum-85Kpa, the revolution speed is 25r / min, the dispersion is 1200r / min, and the stirring is for 10 minutes. After the second addition, it is high-speed dispersion Mixing, control the solid content of the dispersion liquid at 58%, the liquid level requirement of the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com