Full-automatic composite self-insulation building block production method

A technology for self-insulation blocks and production methods, which are applied in chemical instruments and methods, mixed operation control, mixed operation control devices, etc., can solve the problems of unreasonable connection of production equipment, inconvenient pouring and pouring cores, and low production efficiency, etc. Achieve good economic and social benefits, high cost performance, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

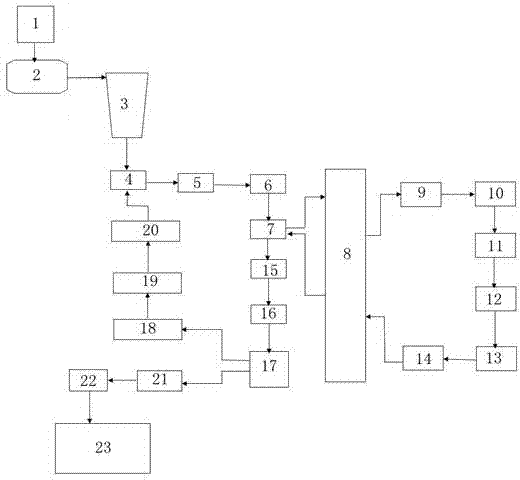

[0027] A fully automatic composite self-insulating block production method, which includes batching, block forming, curing, pallet return and product delivery;

[0028] (1) Ingredients: including shell material ingredients and insulation material ingredients; shell material ingredients: the raw materials of the block shell include sand, gravel, cinder, cement according to cement 15%, cinder 50%, sand 18%, crushed Add 10% stone and 7% water to the premixing tank 1 for mixing, and then enter the mixer 2 for mixing; the sand described in the above step (1) is ordinary sand or medium coarse sand, and the fineness modulus is 2.7~3.1 ;The particle size of the gravel: 5~10mm; Volume specific gravity: 1400~1800kg / m3; Mud content: <3%; The cinder is crushed to within 10mm; The electronic scale under the warehouse automatically measures, and the measured foam stabilizing enhancer is stored in the buffer warehouse, and is added into the mixer through the induction of the sensor toget...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com