Patents

Literature

47results about How to "Improve curing depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

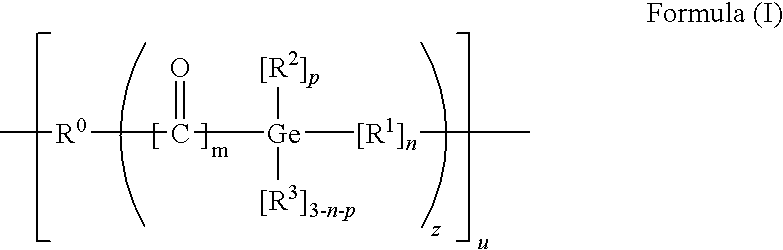

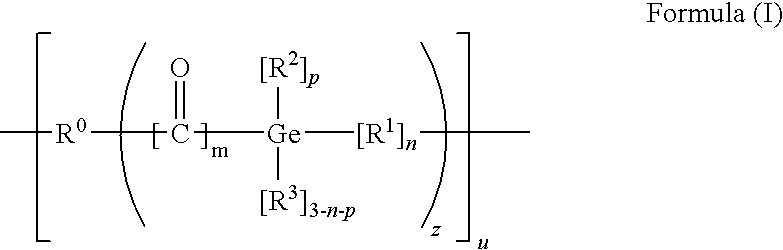

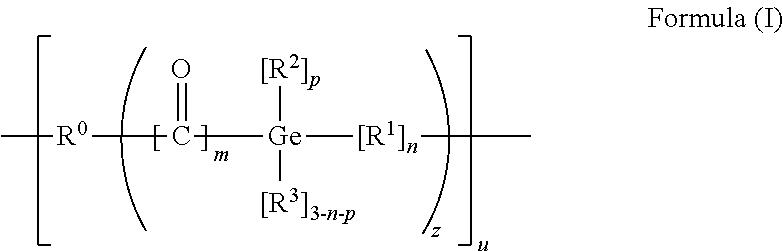

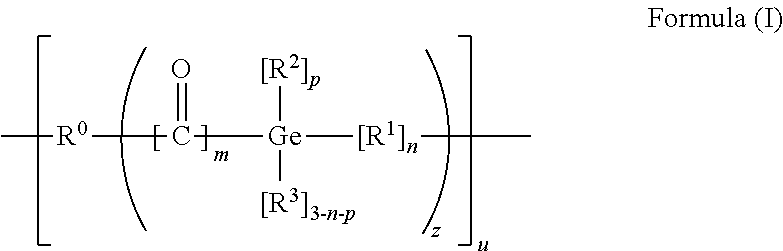

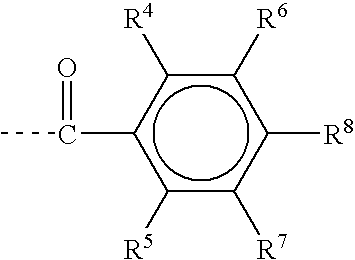

Polymerizable compositions with initiators containing several ge atoms

ActiveUS20090239967A1Improve curing depthFast curingGermanium organic compoundsPhotomechanical apparatusCombinatorial chemistryDental restoration

Composition with at least one polymerizable binder and one polymerization initiator, which contains at least one acylgermanium compound according to general Formula (I),and the use of acylgermanes of Formula (I) as initiators for radical polymerization or for the preparation of dental restorations.

Owner:IVOCLAR VIVADENT AG

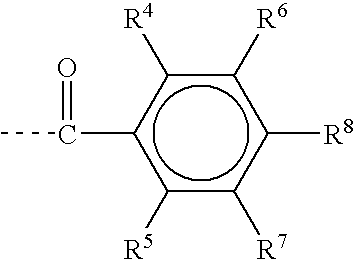

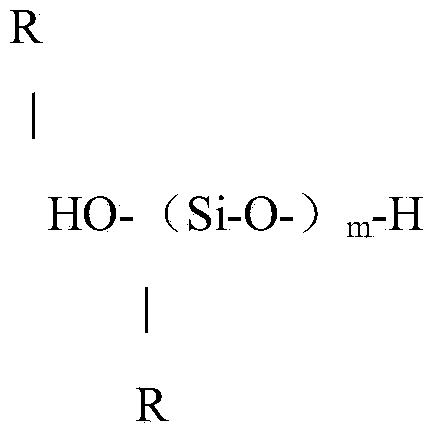

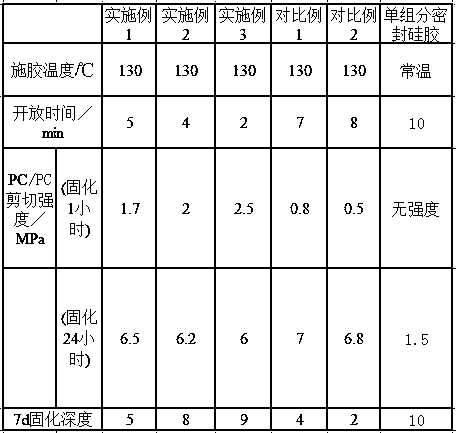

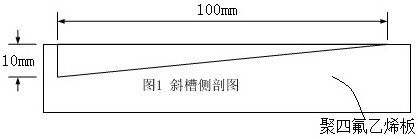

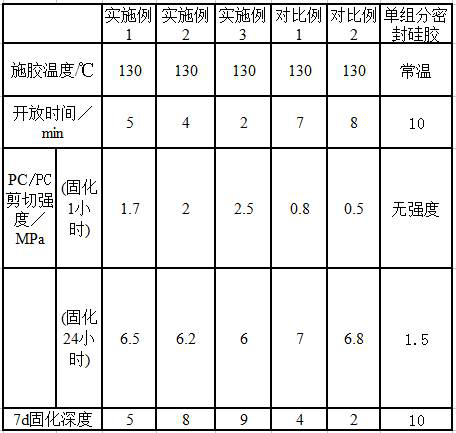

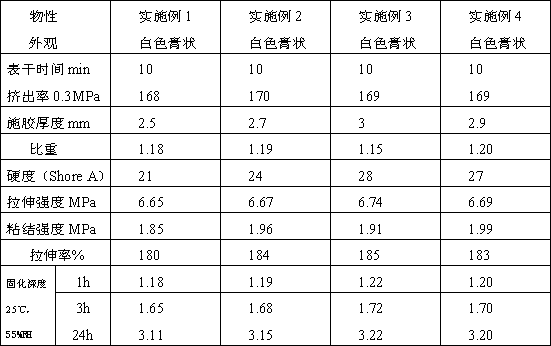

Organic silicon rubber waterproof adhesive and preparation method thereof

InactiveCN103387811AImprove curing depthHigh bond strengthNon-macromolecular adhesive additivesSilane couplingChemistry

The invention discloses an organic silicon rubber waterproof adhesive and a preparation method thereof. The preparation method comprises the steps of: firstly, respectively feeding 20-40 parts by weight of hydroxyl-terminated polysiloxane, 4-7 parts by weight of a reinforcing agent, 41-60 parts of inorganic filler and 2-5 parts of inorganic adsorbent into a stirrer, mixing, and continuously discharging the mixed adhesive material; continuously feeding the mixed adhesive material into a material tank under a reduced pressure state by a pump and continuously degassing in the material tank; continuously feeding the degassed adhesive material into a static mixer, and meanwhile continuously feeding a mixture of 1-3 parts of a crosslinking agent and 0.2-0.8 part of a catalyst into the static mixer by a horizontal closed type continuous kneader; continuously feeding the statically-mixed adhesive material into a double-screw mixing extruder and meanwhile, continuously refilling 0.2-0.8 part of a silane coupling agent and 0.5-3 parts of a curing catalyst through a dropwise filling hole with pressure in the double-screw mixing extruder; mixing the adhesive material in the double-screw mixing extruder, continuously feeding the adhesive material into the mixer for degasing, and finally packaging.

Owner:FUJIAN RUISEN CHEM

Polymerizable compositions with initiators containing several Ge atoms

ActiveUS8829067B2Improve curing depthFast curingGroup 4/14 element organic compoundsImpression capsCombinatorial chemistryDental restoration

Composition with at least one polymerizable binder and one polymerization initiator, which contains at least one acylgermanium compound according to general Formula (I),and the use of acylgermanes of Formula (I) as initiators for radical polymerization or for the preparation of dental restorations.

Owner:IVOCLAR VIVADENT AG

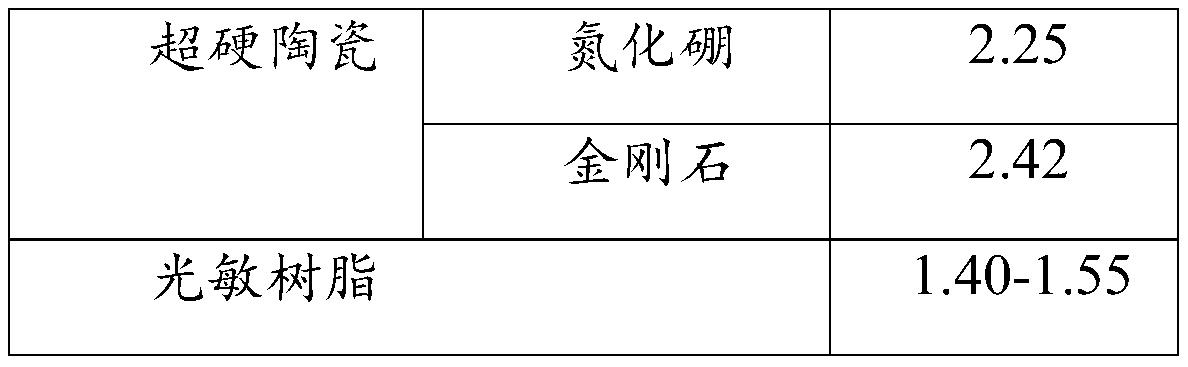

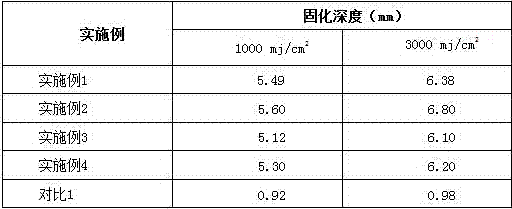

Silicon carbide ceramic paste for photocuring and preparation method thereof

InactiveCN110451985AImprove curing depthReduce clumpingAdditive manufacturing apparatusCeramic sinteringDispersity

The invention discloses silicon carbide ceramic paste for photocuring and a preparation method thereof. The paste is prepared by mixing SiC mixed powder, a dispersing agent, a monomer, a compatilizerand a photoinitiator, wherein the surface of the SiC mixed powder is coated with a SiO2 layer, so that the refractive index difference between the final paste and light-cured resin is reduced, and then printing efficiency is further improved. SiO2 can improve the solid phase content of the whole slurry, so that the sintering density of sintered ceramic and the mechanical property of finally formedceramic can be improved during subsequent ceramic sintering. Through addition of the dispersing agent into the slurry, the agglomeration phenomenon of the slurry can be reduced, the dispersity is improved, and the solid phase content of the whole slurry can be increased. Verification finds that the solid phase content in the paste can finally reach 40%-60%.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

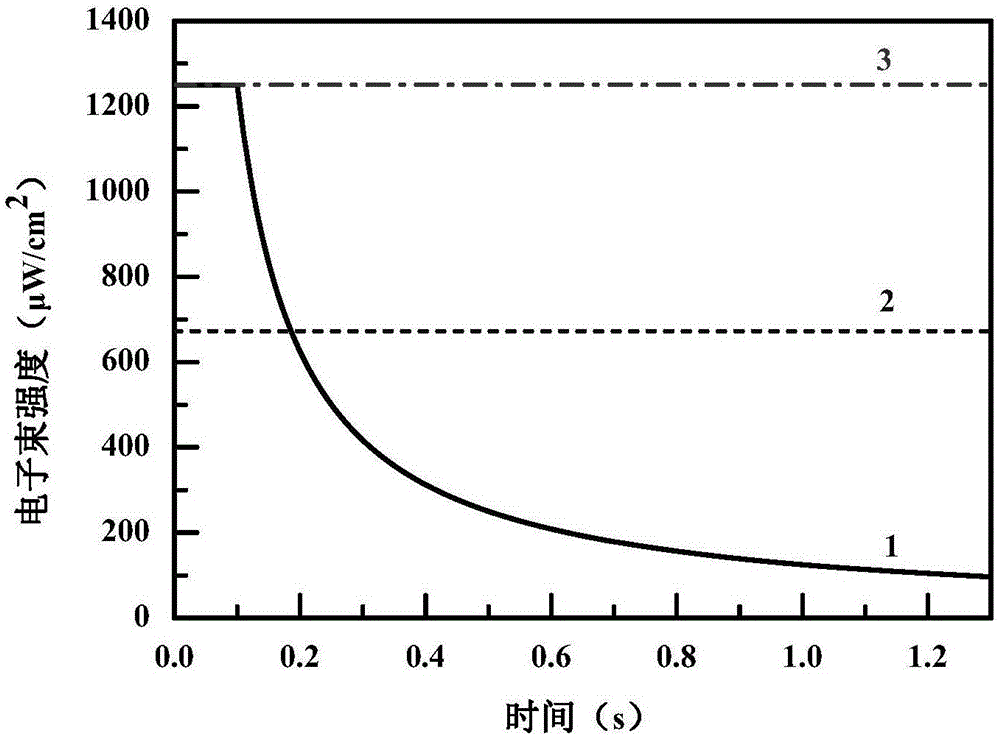

Electron beam radiation curing coating for metal heavy anti-corrosion

ActiveCN106433258AImprove curing efficiencyReduce energy consumptionAnti-corrosive paintsBeam energyOligomer

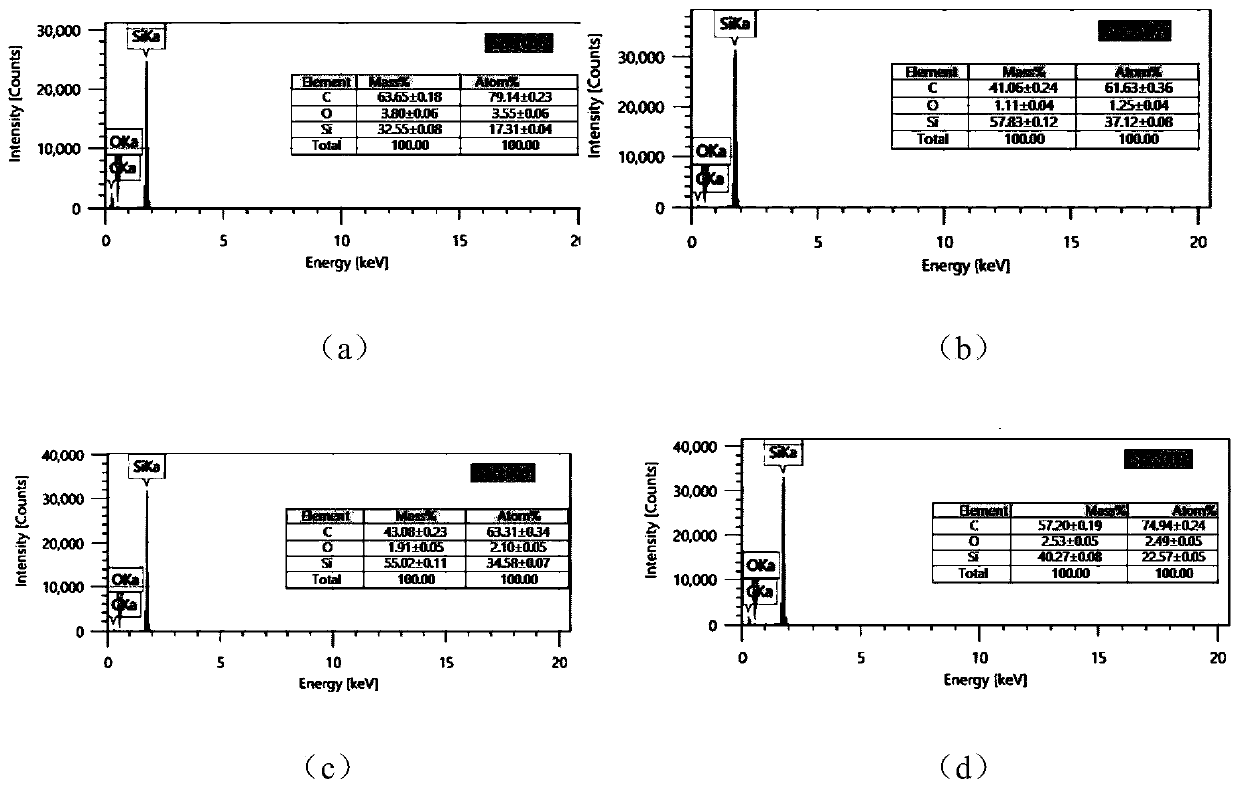

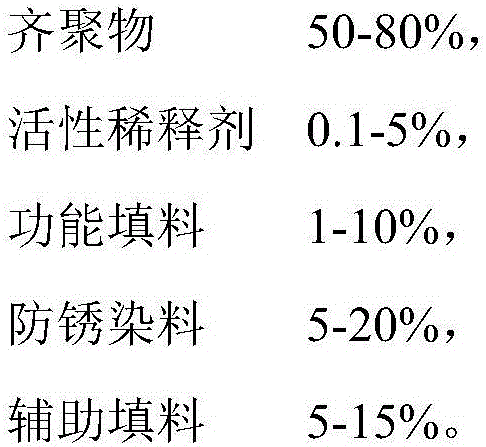

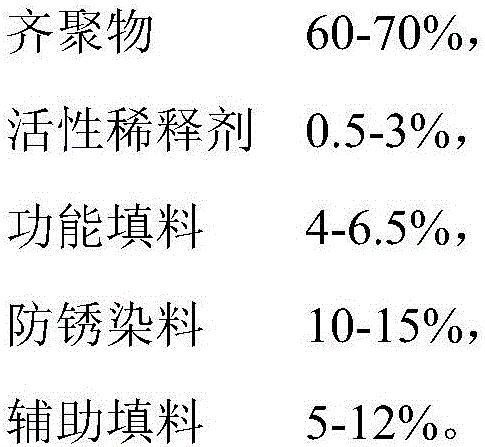

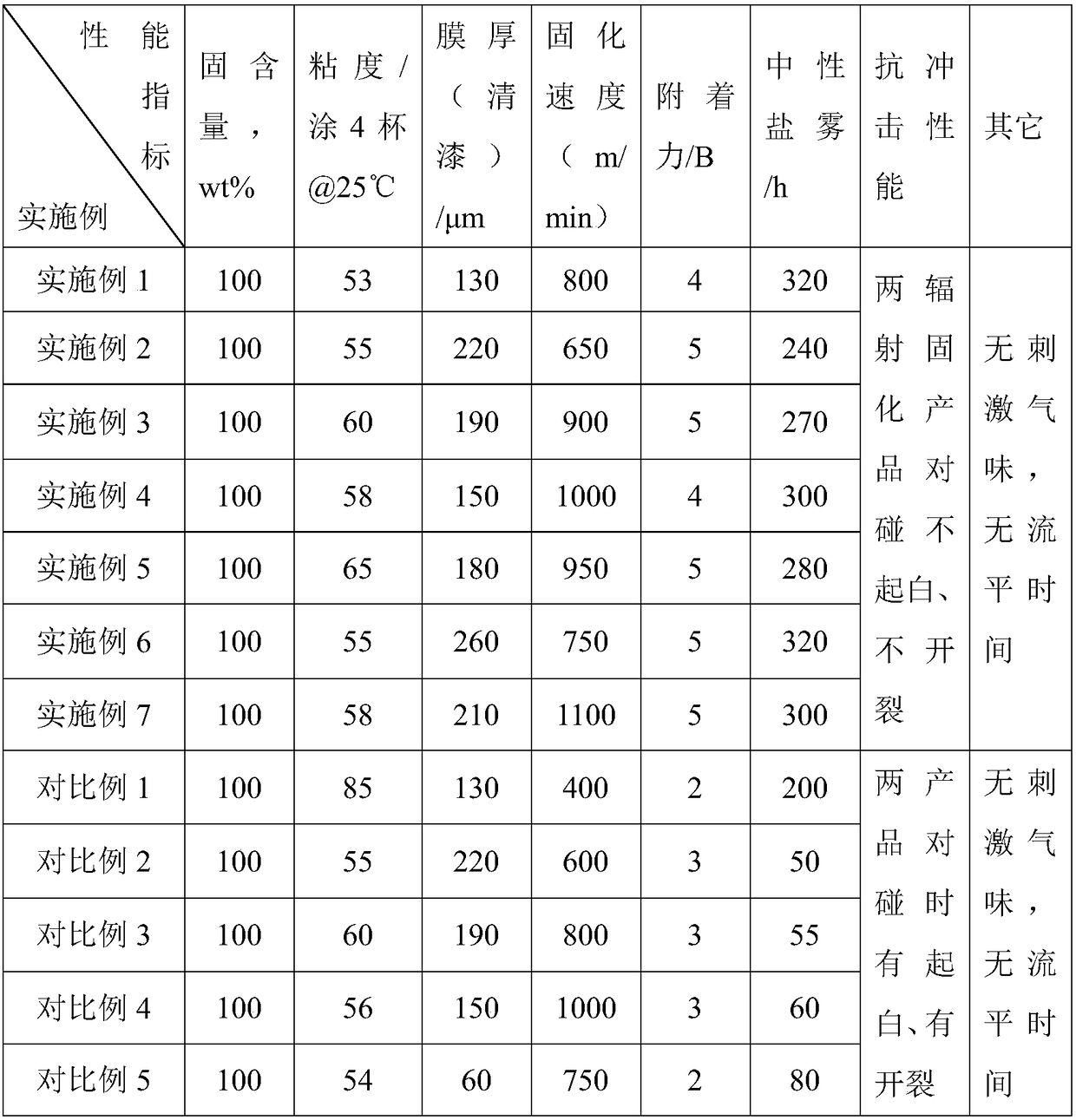

The invention discloses an electron beam radiation curing coating for metal heavy anti-corrosion. The coating is prepared from, by mass, 50%-80% of oligomer, 0.1-0.5% of reactive diluent, 1-10% of functional filler, 5-20% of antirust dyestuff and 5-15% of auxiliary filler, and the total mass percentage of the components is 100%. The curing coating for metal heavy anti-corrosion is cured by electron beam radiation, has the advantages of high efficiency and energy conservation, environment friendship and convenient operation, cured depth of the coating is high, thickness is big, and the adhesive force between the coating and the substrate is strong. A conductive carbon material is doped in the curable coating, thus the problem of metal heavy anti-corrosion is solved while electron beam energy absorption is avoided, and it is guaranteed that cured efficiency is not affected. The electron beam radiation curing coating for metal heavy anti-corrosion has excellent wear-resistance and corrosion-resistance, can be applied to the field of metal heavy anti-corrosion anti-corrosion, and is particularly applicable to the field of maritime work heavy anti-corrosion.

Owner:NANJING INST OF TECH +1

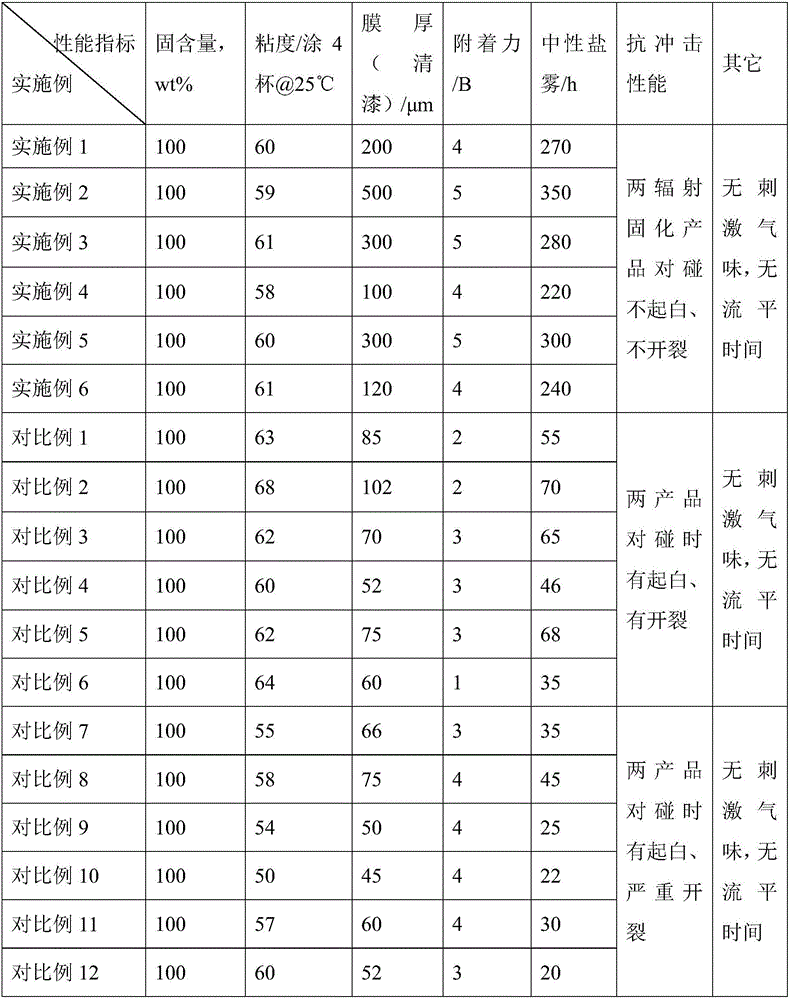

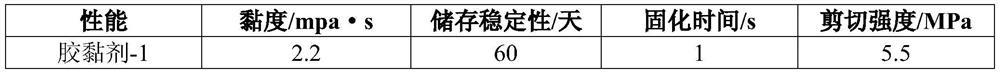

Epoxy resin-modified acrylic resin double-curing system needle adhesive and preparation method thereof

ActiveCN108753228AImprove performanceImprove curing depthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcrylic resinAdhesive

The invention discloses an epoxy resin-modified acrylic resin double-curing system needle adhesive. The adhesive comprises the following raw materials by weight: 20-80 parts of epoxy resin, 5-60 partsof modified acrylic resin, 2-20 parts of epoxy reactive diluent, 2-30 parts of acrylate reactive diluent, 2-20 parts of latent curing agent, 0.2-5 parts of photoinitiator and 0.1-3 parts of sensitizer. A preparation method and an application of the epoxy resin-modified acrylic resin double-curing system needle adhesive are further disclosed. The epoxy resin-modified acrylic resin double-curing system needle adhesive has the advantages of 'quick drying' and 'high strength', and an adhesive condensate has the advantages of high bonding strength, small volume shrinkage, good damp heat resistanceand solvent resistance and moderate price.

Owner:浙江航通舟新材料科技股份有限公司

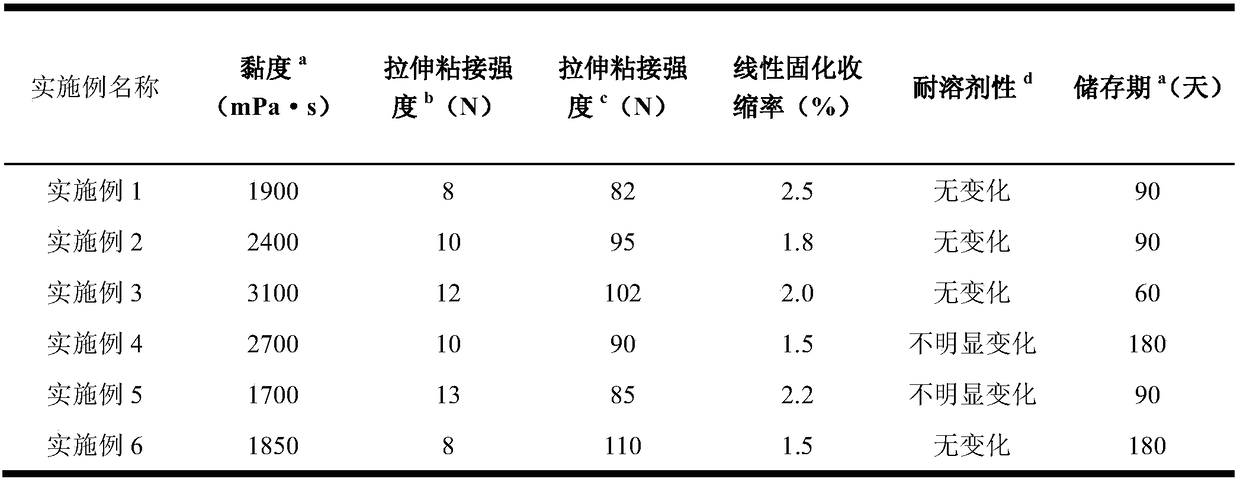

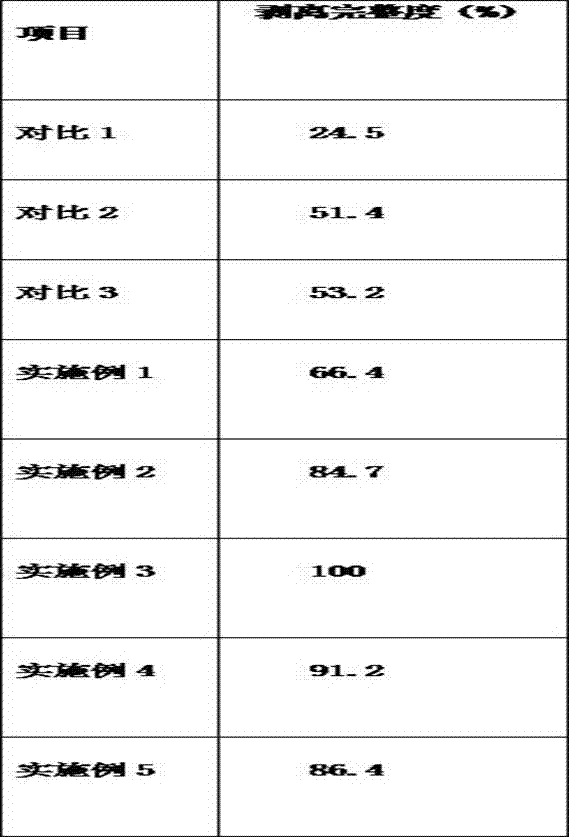

Ultraviolet-curing adhesive and preparation method of same

ActiveCN107502271ASuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

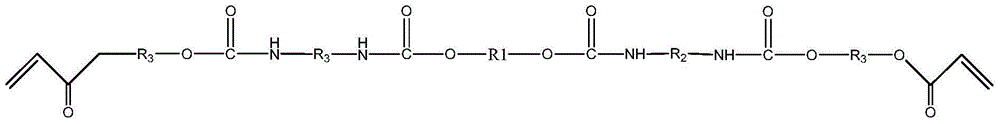

The invention relates to an ultraviolet-curing adhesive and a preparation method of same. The ultraviolet-curing adhesive is composed of, by weight, 20-60 parts of a self-made bifunctional polyurethane-acrylate prepolymer, 5-15 parts of a multifunctional polyurethane-acrylate prepolymer, 5-15 parts of a polyester-acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of an acrylate-type activity diluent, 0.5-5% of a flatting and wetting agent, 1-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nano-powder, and 0.1-10 parts of fumed silica. The ultraviolet light curing adhesive is suitable for temporary protection for metal shells, has protective effect during a later-period treatment process of CNC and can be easily stripped-off after the CNC machining. The adhesive has no residue and stripping off on the metal shells.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

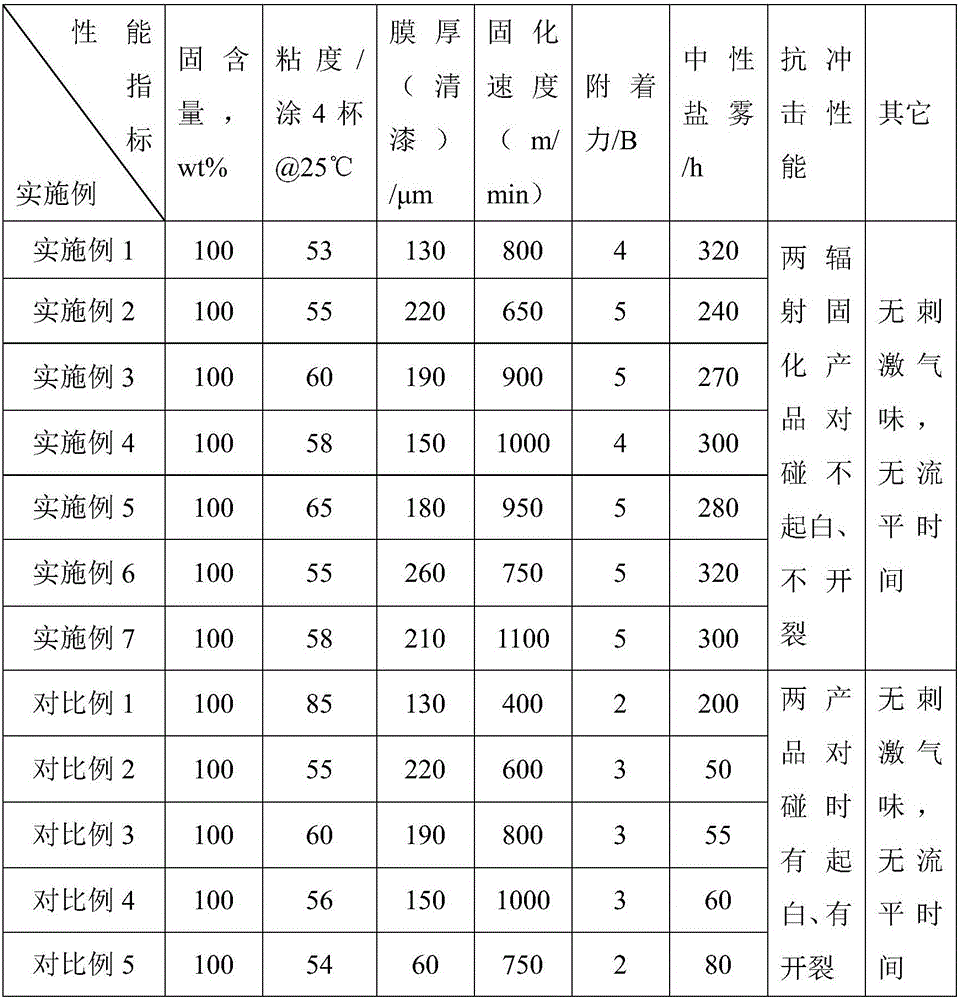

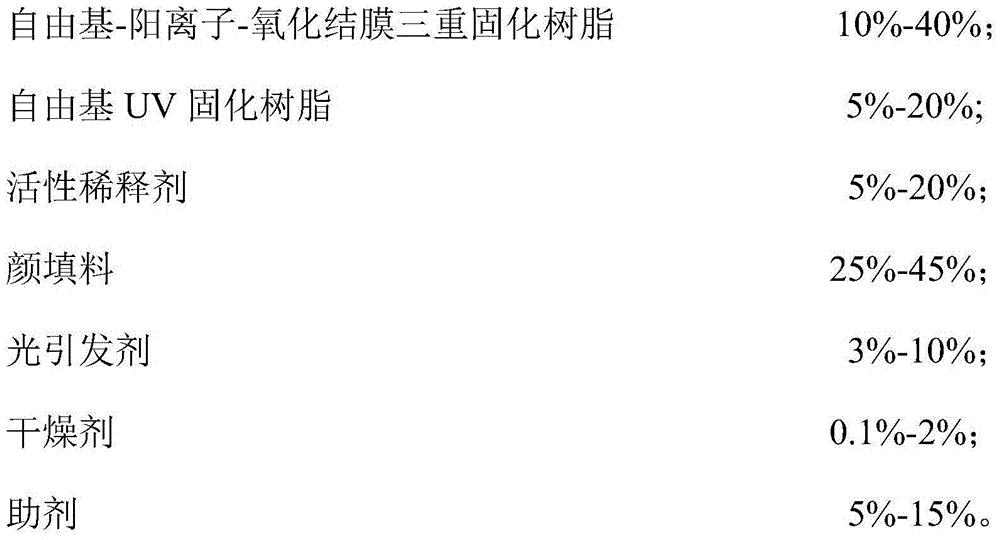

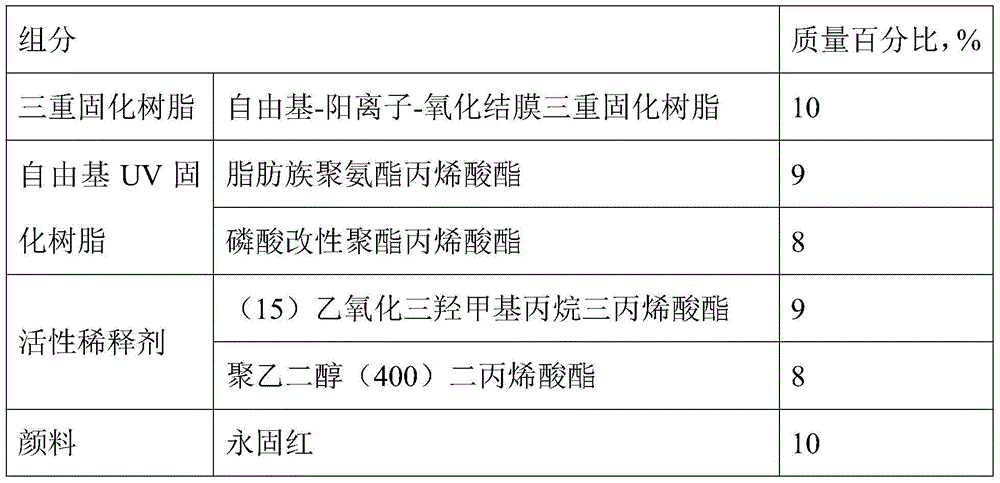

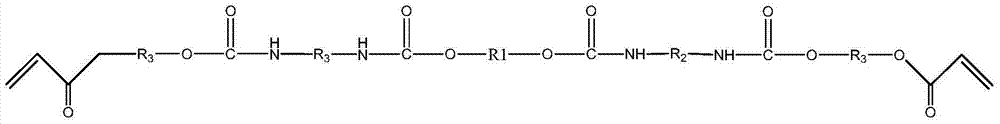

Free radical, cation and air drying tertiary curing intaglio ink

ActiveCN104861770AAvoid Drying Disadvantages of Their RespectiveDry fastInksUV curingSolvent evaporation

The invention discloses free radial, cation and air drying tertiary curing intaglio ink. The ink comprises components in percentage by weight as follows: 10%-40% of free radical, cation and air drying tertiary curing resin, 5%-20% of radical UV (ultraviolet) curing resin, 5%-20% of a reactive diluent, 25%-45% of pigment and filler, 3%-10% of a photoinitiator, 0.1%-2% of a drying agent and 5%-15% of an auxiliary agent. The intaglio ink is prepared with the tertiary curing resin as main resin, so that the advantages of the three curing modes of UV-light free radicals, UV-light cations and air drying can be fully performed, and defects of an UV-light photocuring system and air drying are avoided. The intaglio ink solves technical problems that thick ink film drying of existing free radical UV curing gravure ink is incomplete and traditional air drying type gravure ink is prone to set-off, so that the purposes of shortening of a reprinting cycle, set-off avoidance, no solvent evaporation and the like are achieved, and the intaglio ink has the advantages of economy, energy conservation, environmental protection and the like.

Owner:CHINA BANKNOTE INK +1

Blue light curing ink composition for textile and digital jet printing and curing method thereof

The invention relates to the technical field of light curing ink, and in particular relates to a blue light curing ink composition for textile and a digital jet printing and curing method of the blue light curing ink composition. The blue light curing ink composition for textile comprises a first component and a second component, wherein the first component comprises oligomer and active diluent, and the oligomer accounts for 40-60wt% of the total weight of the oligomer and the active diluent; the second component comprises 0.25-1wt% of blue light initiator, 0.25-1.5wt% of activating agent, 0.1-5wt% of coloring agent and 0.1-1wt% of dispersion stabilizer by taking the weight of the first component as 100%. According to the blue light curing ink formulation and the digital jet printing processing method of the formulation, monomer and the oligomer are used for replacing macromolecule adhesive, so that the ink is guaranteed to have good stability and fluidity in the digital jet printing process; after digital jet printing, polymerization crosslinking between the monomer and the oligomer can be rapidly triggered on the surface of the fiber fabric by the ink on the printed fabric within a few minutes, even tens of seconds under the irradiation of blue light.

Owner:ZHEJIANG SCI-TECH UNIV

Ultraviolet curing adhesive for temporary protection and preparation method of ultraviolet curing adhesive

ActiveCN107474786ASuitable Thixotropic ViscosityReduce hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterNanowire

The invention relates to an ultraviolet curing adhesive for temporary protection and a preparation method of the ultraviolet curing adhesive. The ultraviolet curing adhesive is prepared from the following raw materials by weight: 20-60 parts of a self-made bifunctional polyurethane acrylate prepolymer, 5-15 parts of a multi-functional polyurethane acrylate prepolymer, 5-15 parts of a polyester acrylate prepolymer, 5-20 parts of a reactive amine compounding agent, 10-30 parts of acrylate type active diluents, 0.5%-5% of a leveling wetting agent, 1%-5% of a photoinitiator, 0.5-5 parts of titanium dioxide nanowires and 0.1-10 parts of fumed silica. The ultraviolet curing adhesive is suitable for temporary protection of a metal casing and plays a protective role in post-processing of CNC, and can be easily peeled off after CNC processing. Residues on the metal casing and falling off of the adhesive are avoided.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Dual-cured ceramic material for additive manufacturing and preparation method and application of dual-cured ceramic material

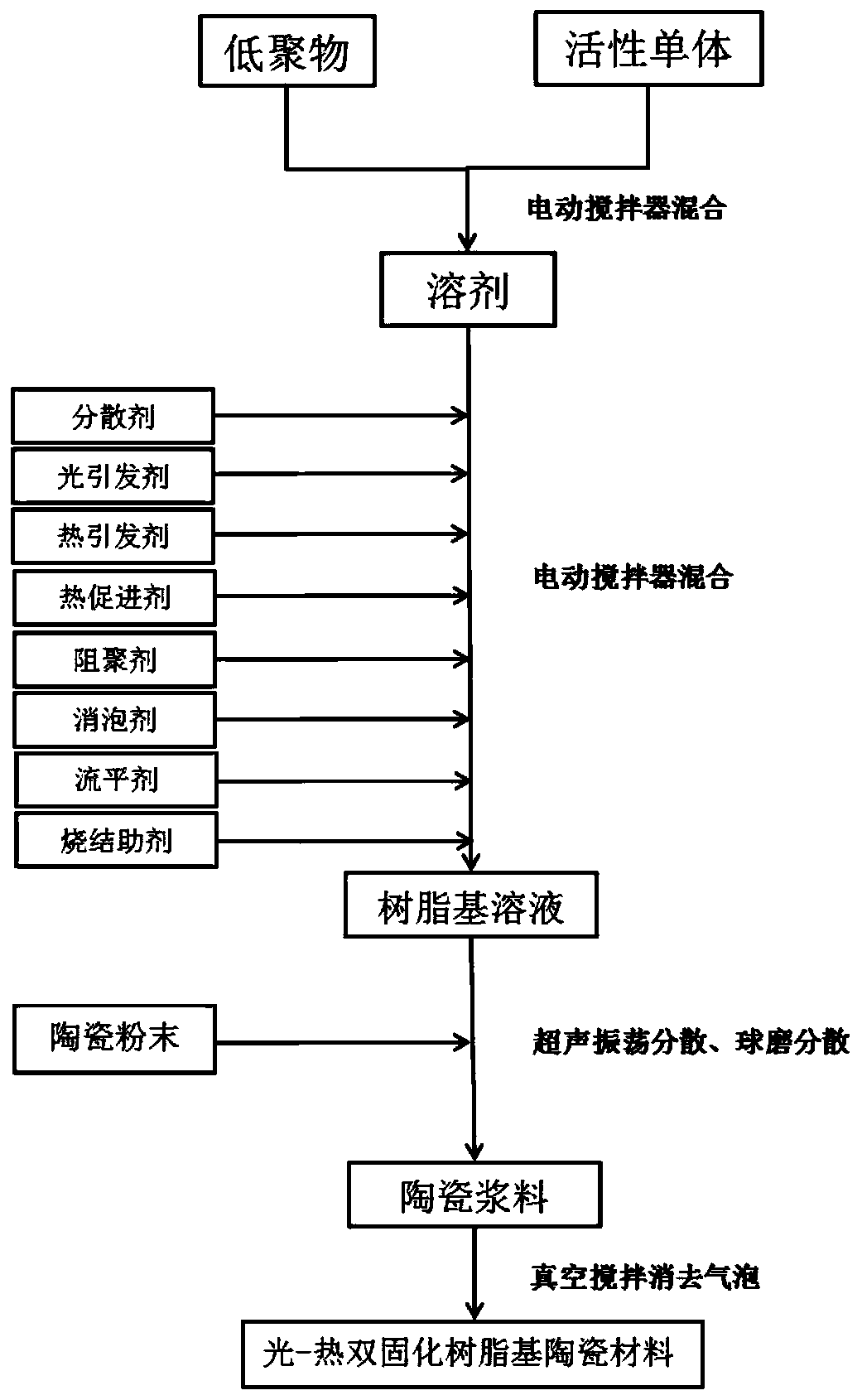

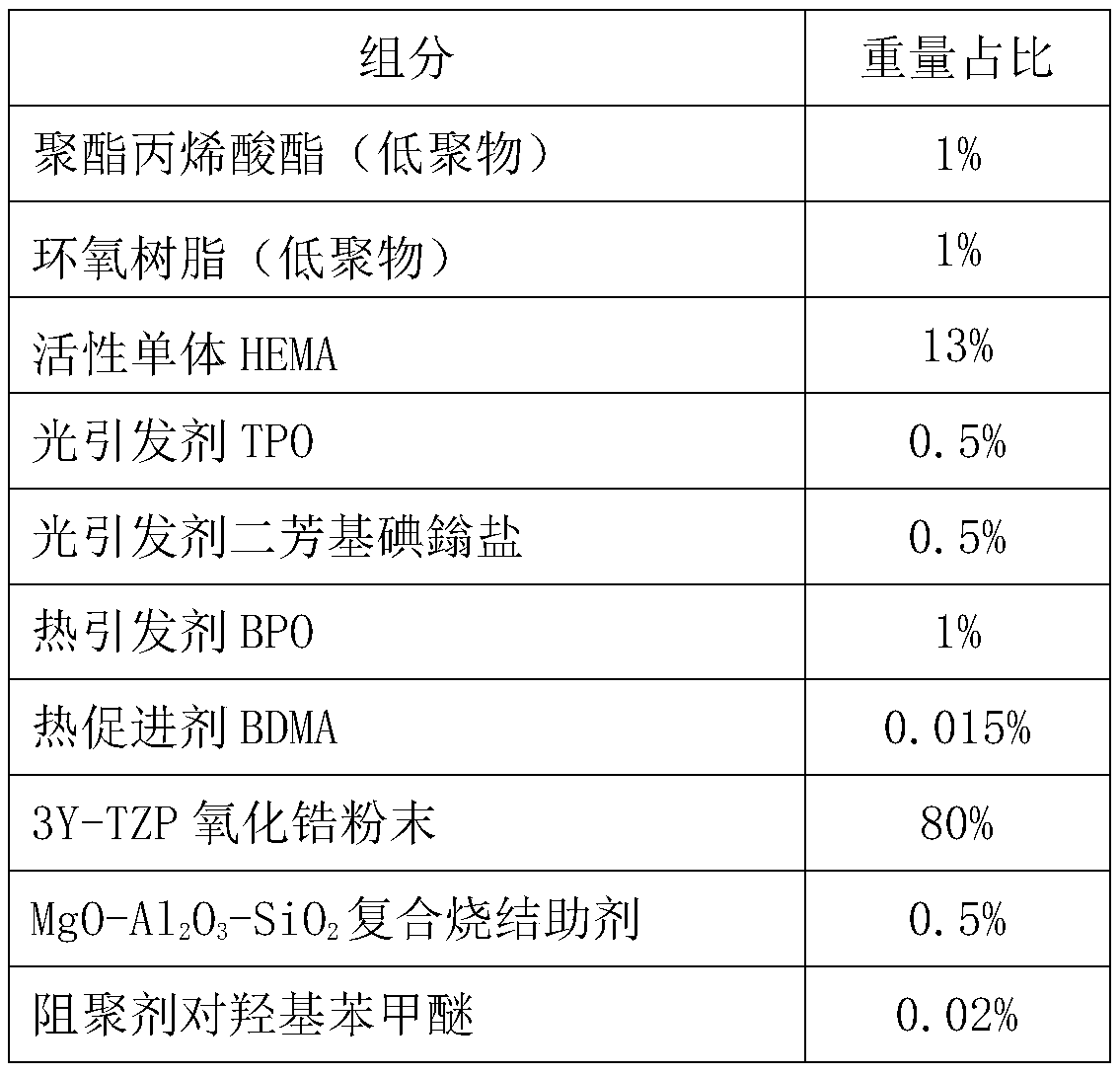

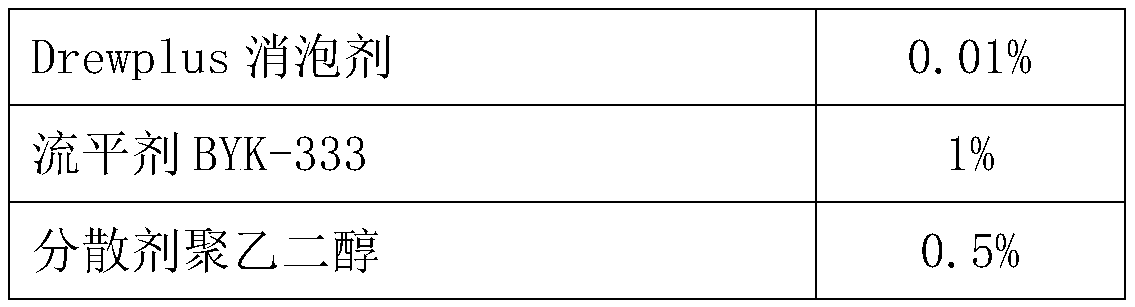

The present application discloses a dual-cured ceramic material for additive manufacturing and a preparation method and application of the dual-cured ceramic material. The preparation method comprisesthe steps that an oligomer and a reactive monomer are stirred and mixed to obtain a solvent; a dispersant is added into the solvent to uniformly disperse liquid; a photoinitiator, a thermal initiatorand a thermal curing accelerator are added, and after each reagent is added, the solution is fully stirred until uniform mixed; a defoamer, a polymerization inhibitor, a leveling agent and a sintering aid are added to obtain a resin-based solution, and after each reagent is added, the solution is fully stirred until uniform mixed; ceramic powder is dispersed in the resin-based solution, and ball-milling is carried out on the prepared material after the dispersion is completed; and after the material is ball-milled to be uniform, the obtained material is evacuated and stirred to eliminate airbubbles. The dual-cured ceramic material is prepared by the preparation method. The dual-cured ceramic material can be applied to additive manufacturing. The solidification depth of materials can be increased.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

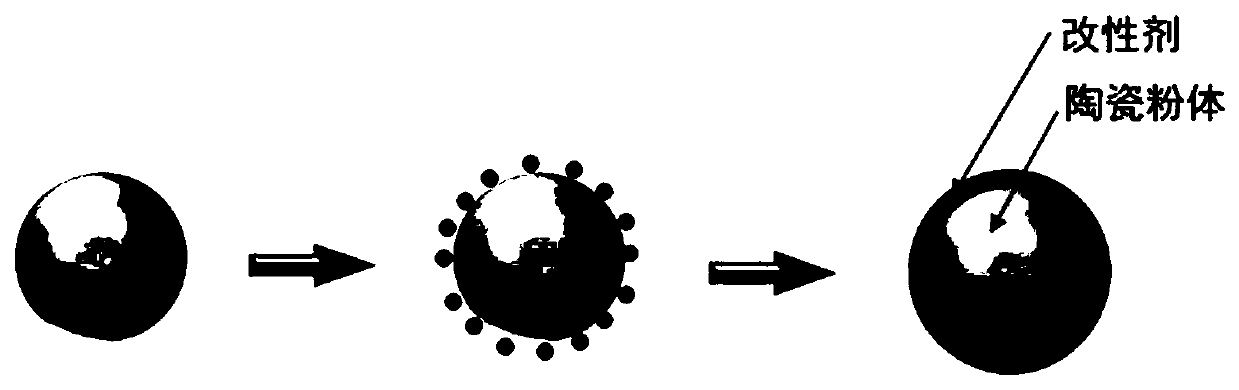

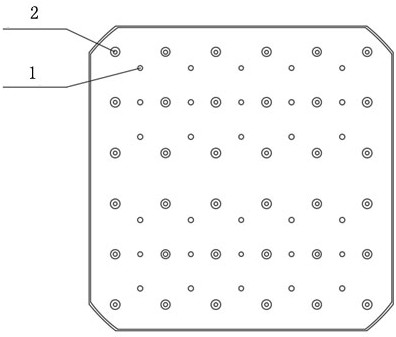

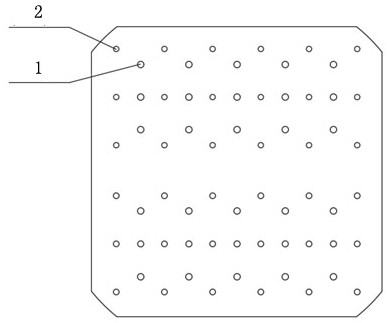

3D printing light-cured ceramic particle and preparation method thereof

InactiveCN111320480APrecise thickness controlPrecise control of ingredientsAdditive manufacturing apparatus3d printLight absorption coefficient

The invention provides a 3D printing light-cured ceramic particle and a preparation method thereof. The 3D printing photocuring ceramic particle comprises a ceramic matrix; wherein the surface of theceramic matrix is coated with a coating layer; and the coating layer is a sintering aid layer, and the sintering aid layer coats the ceramic matrix according to the decreasing order of the refractiveindexes of the sintering aid components. The 3D printing light-cured ceramic particle is prepared by a precipitation method, the thickness and components of the coating layer can be accurately controlled, and meanwhile, a proper coloring agent is added to adjust the light absorption coefficient, so that the 3D printing light-cured ceramic particle is more suitable for the requirements of a ceramiclight-cured molding technology.

Owner:GUANGDONG INST OF NEW MATERIALS

Reactive hot melt adhesive composition as well as preparation method and application thereof

ActiveCN109233731AQuick responseImprove curing depthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolymer science

The invention relates to the field of high molecular materials and discloses a reactive hot melt adhesive composition. The reactive hot melt adhesive composition comprises the following components inpercentage by weight: 55-80 percent of a bi-functional and / or poly-functional isocyanate terminated pre-polymer, 2-20 percent of tackifying resin, 5-30 percent of silane-modified silicone resin, 0.01-1 percent of a cross-linking agent and 1-10 percent of fumed silica as well as an optional additive. The invention further discloses a preparation method and application of the reactive hot melt adhesive composition. The reactive hot melt adhesive composition has relatively high curing speed and is especially suitable for the lighting industry.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Preparation method of extensible solidifiable UV-LED cation solidifying adhesive

ActiveCN108003823AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPhotosensitizer

The invention relates to a preparation method of an extensible solidifiable UV-LED cation solidifying adhesive. The extensible solidifiable UV-LED cation solidifying adhesive is prepared from, by weight, 30 to 55 parts of liquid epoxy resin, 0.01 to 0.5 part of MoS2 nanometer hollow ball, 5 to 20 parts of an active diluents, 10 to 30 parts of a filling material, 1 to 5 parts of a cation photoinitiator, 0.1 to 2.5 parts of a photosensitizer, 0.05 to 0.5 part of a pigment, 1 to 5 parts of a thixotropic agent, and 1 to 5 parts of an auxiliary agent. According to the preparation method, MoS2 nanometer hollow ball is added into colloid, is used for replacing a part of the pigment, can be taken as a scatterer, is capable of solving problems in the prior art that the solidification depth of conventional colored UV-LED cation solidifying adhesive is low, and solidification of bottom adhesive layers is difficult to realize; and the application range is wide.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

Light curing adhesive and light curing method thereof

InactiveCN109321146AImprove curing depthMeet high chroma requirementsNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesivePhotoinitiator

A light curing adhesive comprises an acrylic prepolymer, an acrylic monomer, a thermochromic pigment and a photoinitiator, wherein the thermochromic pigment shows an initial color at room temperatureand becomes colorless and transparent when the temperature is higher than a preset temperature. The invention also provides a light curing method of the light curing adhesive.

Owner:1ST SPECIAL MATERIAL INT HLDG LTD

Gradual intensity electron beam radiation coating solidification process

ActiveCN106475286AImprove curing efficiencyReduce energy consumptionPretreated surfacesAnti-corrosive paintsHigh energyUltimate tensile strength

The invention discloses a gradual intensity electron beam radiation coating solidification process. The invention bases on the solidification technics of electron beam radiation, adopts a solidifying form of gradual intensity, and mainly is used for solidifying coating with thickness at 100Mum-500Mum, the electron beam intensity is accurately controlled by a computer program, and achieves a dynamic coordination with the solidified thickness of the coating. On one hand, the process bases on the solidification of electron beam radiation, solves the problems of high energy consumption and inadequate depth by solidifications of traditional ultraviolet ray, one the other hand, the process adopts a solidifying form of gradual intensity, respectively solidifies the surface and the insides of the coating, further solves the problem of unenven solidifications of an inside and outside layer membrance when intermittently solidifying ultraviolet-electron beam, thereby increases the direct adherence force of the coating and a base material, enables the coating to possess superior abrasion tolerance and anti erosion property, meanwhile the process reduces unnecessary energy consumption when solidifying the electron beam at a single intensity. The obtained coating from the provided solidification process can be applied to the field of metal corrosion repreventions, meanwhile can achieve the coating and dressing of rusty surfaces.

Owner:YIXING HONGTAI CHEM +1

A blue light curable ink composition for textiles and digital jet printing curing method thereof

The invention relates to the technical field of light curing ink, and in particular relates to a blue light curing ink composition for textile and a digital jet printing and curing method of the blue light curing ink composition. The blue light curing ink composition for textile comprises a first component and a second component, wherein the first component comprises oligomer and active diluent, and the oligomer accounts for 40-60wt% of the total weight of the oligomer and the active diluent; the second component comprises 0.25-1wt% of blue light initiator, 0.25-1.5wt% of activating agent, 0.1-5wt% of coloring agent and 0.1-1wt% of dispersion stabilizer by taking the weight of the first component as 100%. According to the blue light curing ink formulation and the digital jet printing processing method of the formulation, monomer and the oligomer are used for replacing macromolecule adhesive, so that the ink is guaranteed to have good stability and fluidity in the digital jet printing process; after digital jet printing, polymerization crosslinking between the monomer and the oligomer can be rapidly triggered on the surface of the fiber fabric by the ink on the printed fabric within a few minutes, even tens of seconds under the irradiation of blue light.

Owner:ZHEJIANG SCI-TECH UNIV

Nanometer titanium dioxide ceramic paste material for photocuring and preparation method thereof

The invention discloses a nanometer titanium dioxide ceramic paste material for photocuring and a preparation method thereof. The nanometer titanium dioxide ceramic paste material comprises TiO2 powder, gamma-glycidyl ether oxypropyl trimethoxy silane, sodium hexametaphosphate, a Tego 685 wetting dispersant, a monomer, a compatilizer and a photoinitiator. According to the invention, the monomer with a specified content is added to serve as a dilution paste material, so viscosity effect is reduced, the paste material is prevented from being too thin, the hardness of a photocuring product is improved, and the shrinkage rate of the product is reduced; and high-functional-group resin in the monomer can increase curing depth and improve curing efficiency, and the photoinitiator is cooperativelyused with the monomer, so the action effect of the surface of paste and ultraviolet light is relatively violent, a surface layer of the paste can be initiated to undergo quick curing and to penetrateinto the paste, the stability of the reaction of the surface of the paste and the ultraviolet light is improved, the curing efficiency is further improved, and photocuring molding is facilitated.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

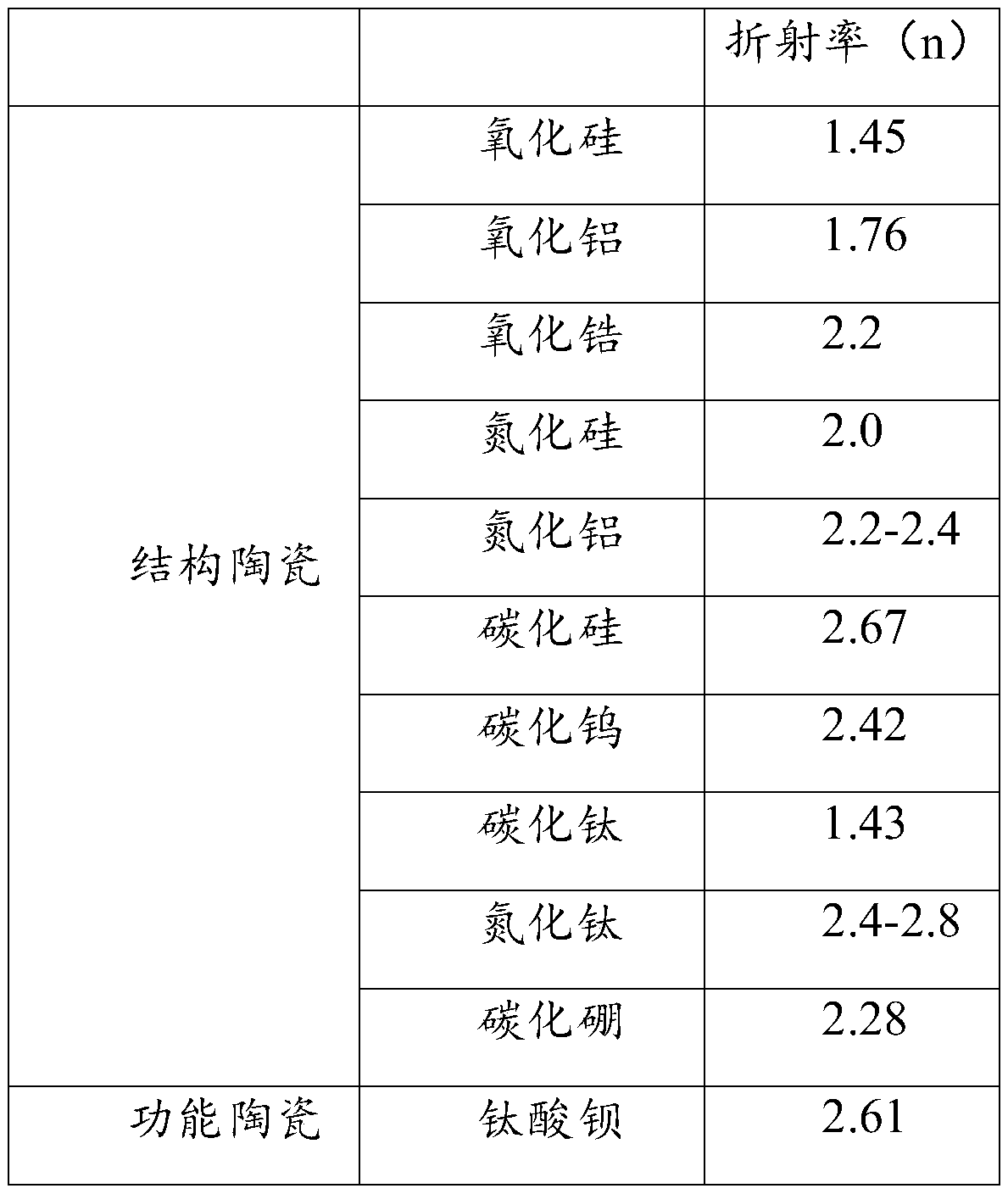

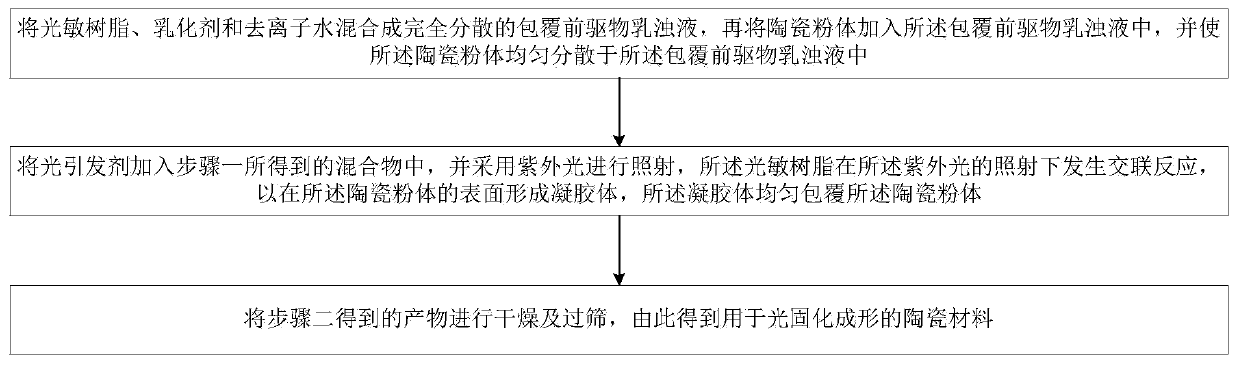

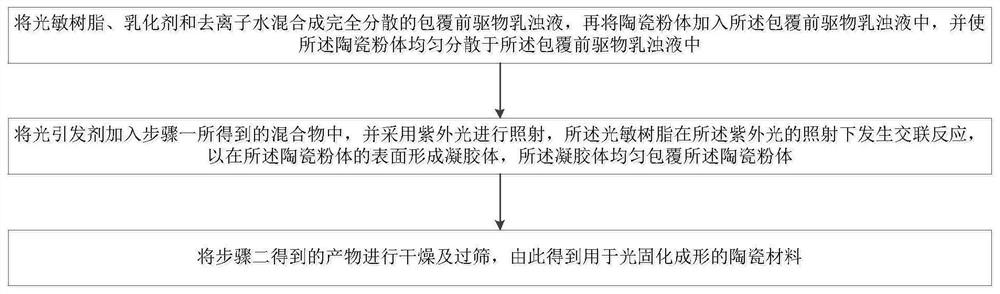

Ceramic material for photocuring forming as well as emulsion coating preparation method and application of ceramic material

ActiveCN111348921AReduce the refractive index differenceReduce absorptionUltraviolet lightsPhotoinitiator

The invention belongs to the related technical field of ceramic materials. The invention discloses a ceramic material for photocuring forming as well as an emulsion coating preparation method and application of the ceramic material. The method comprises the following steps: (1) mixing a photosensitive resin, an emulsifier and deionized water to form a completely dispersed coating precursor emulsion, adding ceramic powder into the coating precursor emulsion, and uniformly dispersing the ceramic powder into the coating precursor emulsion; and (2) adding a photoinitiator into a mixture obtained in the step (1), irradiating with ultraviolet light, carrying out a cross-linking reaction on the photosensitive resin under the irradiation of the ultraviolet light to form a gel on the surface of theceramic powder, and uniformly coating the ceramic powder with the gel to obtain the ceramic material. The method is environmentally friendly, low in cost, high in universality, simple in process, short in preparation period and capable of effectively solving the photocuring manufacturing problem of ceramic parts such as silicon nitride and titanium dioxide.

Owner:HUAZHONG UNIV OF SCI & TECH

A reactive hot melt adhesive composition and its preparation method and application

ActiveCN109233731BQuick responseImprove curing depthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCross linker

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

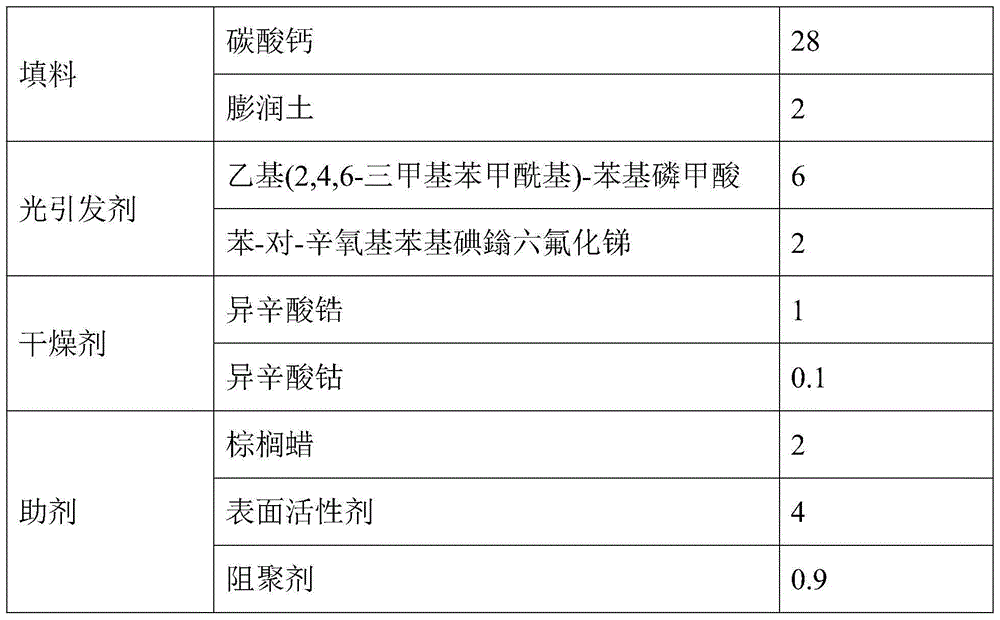

Free radical-positive ion-oxide conjunctiva triple curing resin and preparation method thereof

The invention discloses free radical-positive ion-oxide conjunctiva triple curing resin and a preparation method thereof. The preparation method comprises the following steps: (1) heating a compound, which contains at least two epoxy groups, and 4-metoxyphenol, dropwise adding unsaturated vegetable oleic acid containing an alkali catalyst, and reacting; (2) dissolving the products obtained in the step (1) in methylene dichloride, adding triethylamine, then dropwise adding acryloyl chloride, and reacting to obtain the free radical-positive ion-oxide conjunctiva triple curing resin. The free radical-positive ion-oxide conjunctiva triple curing resin and the preparation method can solve the problems that a thick film is incomplete in drying and a dark coating film is not easy to dry; the free radical-positive ion-oxide conjunctiva triple curing resin is high in curing speed, high in curing degree and low in curing shrinkage, and has the advantages of being economical, energy-saving, environment-friendly and the like.

Owner:CHINA BANKNOTE INK +1

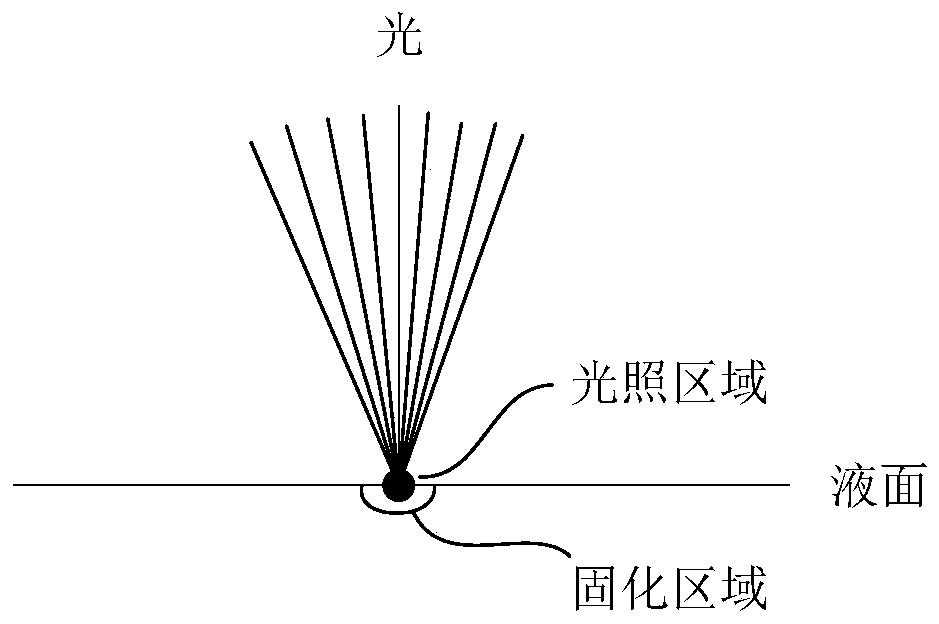

3D printing method and device based on thermocuring mechanism

PendingCN111070672AAchieve solidificationImprove curing depthAdditive manufacturing apparatus3D object support structuresLiquid stateEngineering

The embodiment of the invention discloses a 3D printing method and device based on a thermocuring mechanism. The 3D printing method comprises the step that a light source is used for irradiating liquid slurry which generates heat by absorbing light and is subjected to thermocuring according to a set path. The device comprises the light source, and the light source can irradiate the liquid slurry which generates heat by absorbing light and is subjected to thermocuring according to the set path. According to the embodiment, the liquid slurry is cured through a thermal initiation mode, and the curing depth can be increased.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

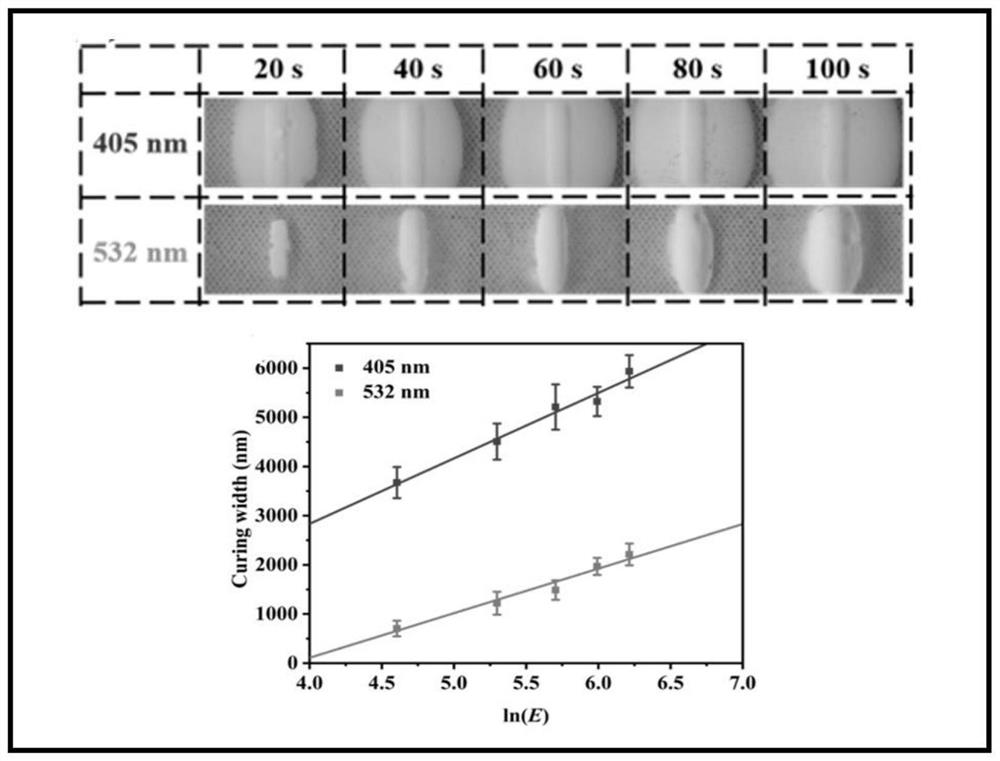

3D printing photosensitive material taking green light as photocuring light source and 3D printer thereof

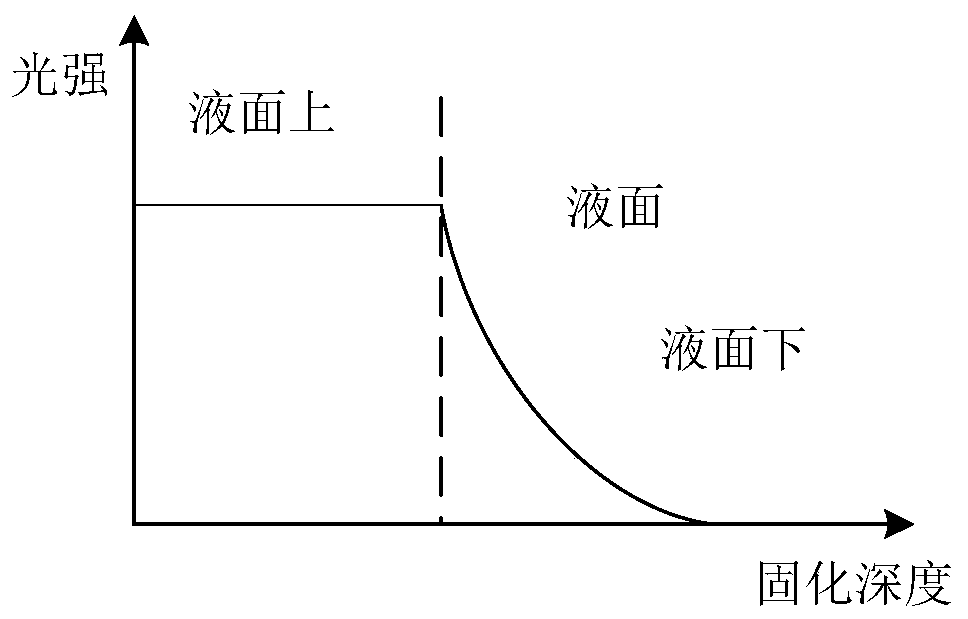

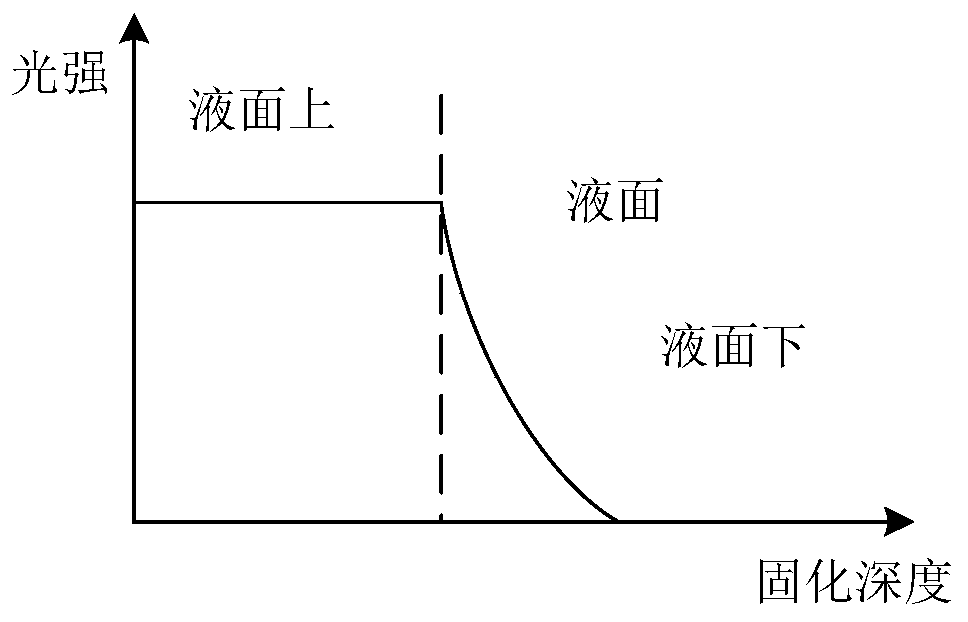

PendingCN114347464AImprove curing depthHigh refractive indexAdditive manufacturing apparatusCeramic shaping apparatus3d printComputer printing

The invention discloses a 3D printing photosensitive material taking green light as a photocuring light source, which at least comprises a green light initiation system, the green light initiation system is a Norrish I type photosensitizer and a Norrish II type photosensitizer which have light absorption initiation capability in a green light wavelength range, and the green light initiation system is a Norrish I type photosensitizer and a Norrish II type photosensitizer which have light absorption initiation capability in a green light wavelength range. Comprising a curcumin compound / onium salt system, a difluoro boron curcumin compound / onium salt system, a ferrocene-containing conjugated indandione compound / onium salt / N-methyl pyrrolidone system, a benzal ketone compound / onium salt system and a benzal ketone compound / amine system. The preparation method has the beneficial effects that on one hand, through the principles that the longer the wavelength is, the lower the light refractive index is, and the longer the wavelength is, the stronger the light penetrability is, the curing depth of the 3D printing material can be remarkably improved, and the problem of interlayer cracking is avoided, especially the 3D printing material with the high refractive index, such as 3D printing photosensitive ceramic slurry; and on the other hand, through the principle that the longer the wavelength is, the lower the light refractive index is, the curing width of the 3D printing material can be remarkably reduced, and the curing and printing precision can be improved, especially the 3D printing material with the high refractive index, such as 3D printing photosensitive ceramic slurry.

Owner:SUN YAT SEN UNIV

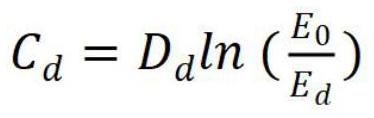

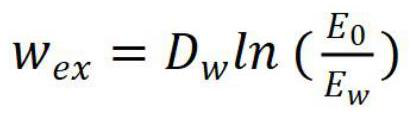

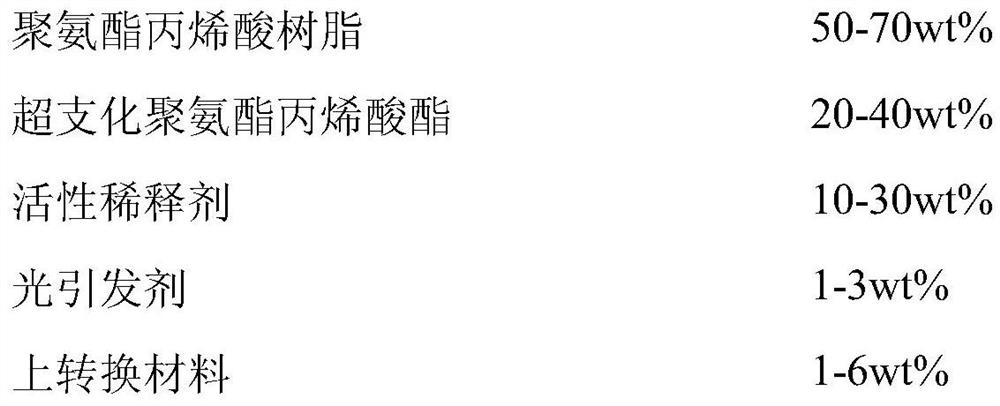

A kind of near-infrared curing polyurethane acrylate adhesive

ActiveCN112646539BImprove curing depthGood compatibilityPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention relates to a near-infrared curing polyurethane acrylate adhesive, which belongs to the field of adhesives. The components of the near infrared curing urethane acrylate adhesive include: urethane acrylate resin, hyperbranched urethane acrylate, active diluent, photoinitiator, and up-conversion nanoparticles. The adhesive has the advantages of high curing depth; the system also has the advantages of low viscosity and increased curing speed, and the technology can realize the curing of colored systems.

Owner:JIANGNAN UNIV

Ceramic material for photocuring and its emulsion coating preparation method and application

ActiveCN111348921BReduce the refractive index differenceReduce absorptionUltraviolet lightsPhotoinitiator

The invention belongs to the related technical field of ceramic materials, and discloses a preparation method and application of a ceramic material for photocuring forming and its emulsion coating. The method includes the following steps: (1) mixing photosensitive resin, emulsifier and Ionized water is mixed into a fully dispersed coating precursor emulsion, and then ceramic powder is added to the coating precursor emulsion, and the ceramic powder is evenly dispersed in the coating precursor emulsion (2) Add the photoinitiator to the mixture obtained in step (1), and irradiate with ultraviolet light, and the photosensitive resin undergoes a crosslinking reaction under the irradiation of ultraviolet light, so that the ceramic A gel is formed on the surface of the powder, and the gel uniformly covers the ceramic powder, thereby obtaining the ceramic material. The invention is environmentally friendly, low in cost, strong in universal applicability, simple in process and short in preparation period, and can effectively solve the problem of photocuring manufacturing of ceramic parts such as silicon nitride and titanium dioxide.

Owner:HUAZHONG UNIV OF SCI & TECH

High-efficiency packaging method for MWT assembly

InactiveCN113690345AInhibition thicknessImprove curing depthPhotovoltaic energy generationSemiconductor devicesPolymer scienceAcrylic resin

The invention provides a high-efficiency packaging method for an MWT assembly, which comprises the following steps of firstly coating polyurethane resin on a conductive metal foil, and performing solvent volatilization and primary curing after passing through a drying tunnel, then spraying epoxy acrylic resin on the surface layer of the polyurethane resin, and curing the epoxy acrylic resin on the surface layer through ultraviolet irradiation, after laser drilling is carried out on the insulating layer, conducting battery piece placement, and finally, laying other materials for producing the assembly, and carrying out secondary lamination curing in a laminating machine. The packaging surface obtained through the method has certain strength and hardness, uneven current caused by layering due to insufficient bonding strength in the long-term outdoor use process is avoided, the lamination subfissure proportion and the glue hole blocking proportion in the lamination process are improved, the lamination time rhythm can be adjusted, the power is improved, and hot spots are improved.

Owner:南京日托光伏新能源有限公司

A kind of electron beam radiation curing coating for metal heavy anticorrosion

ActiveCN106433258BImprove curing efficiencyReduce energy consumptionAnti-corrosive paintsBeam energyOligomer

The invention discloses an electron beam radiation curing coating for metal heavy anti-corrosion. The coating is prepared from, by mass, 50%-80% of oligomer, 0.1-0.5% of reactive diluent, 1-10% of functional filler, 5-20% of antirust dyestuff and 5-15% of auxiliary filler, and the total mass percentage of the components is 100%. The curing coating for metal heavy anti-corrosion is cured by electron beam radiation, has the advantages of high efficiency and energy conservation, environment friendship and convenient operation, cured depth of the coating is high, thickness is big, and the adhesive force between the coating and the substrate is strong. A conductive carbon material is doped in the curable coating, thus the problem of metal heavy anti-corrosion is solved while electron beam energy absorption is avoided, and it is guaranteed that cured efficiency is not affected. The electron beam radiation curing coating for metal heavy anti-corrosion has excellent wear-resistance and corrosion-resistance, can be applied to the field of metal heavy anti-corrosion anti-corrosion, and is particularly applicable to the field of maritime work heavy anti-corrosion.

Owner:NANJING INST OF TECH +1

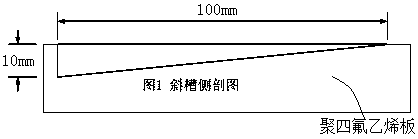

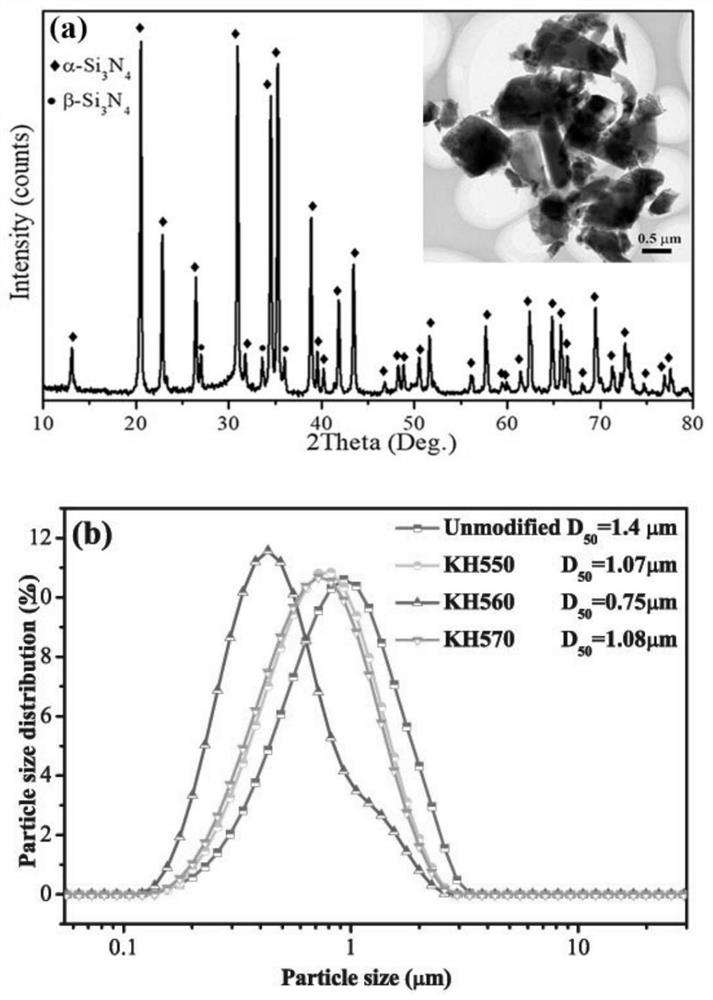

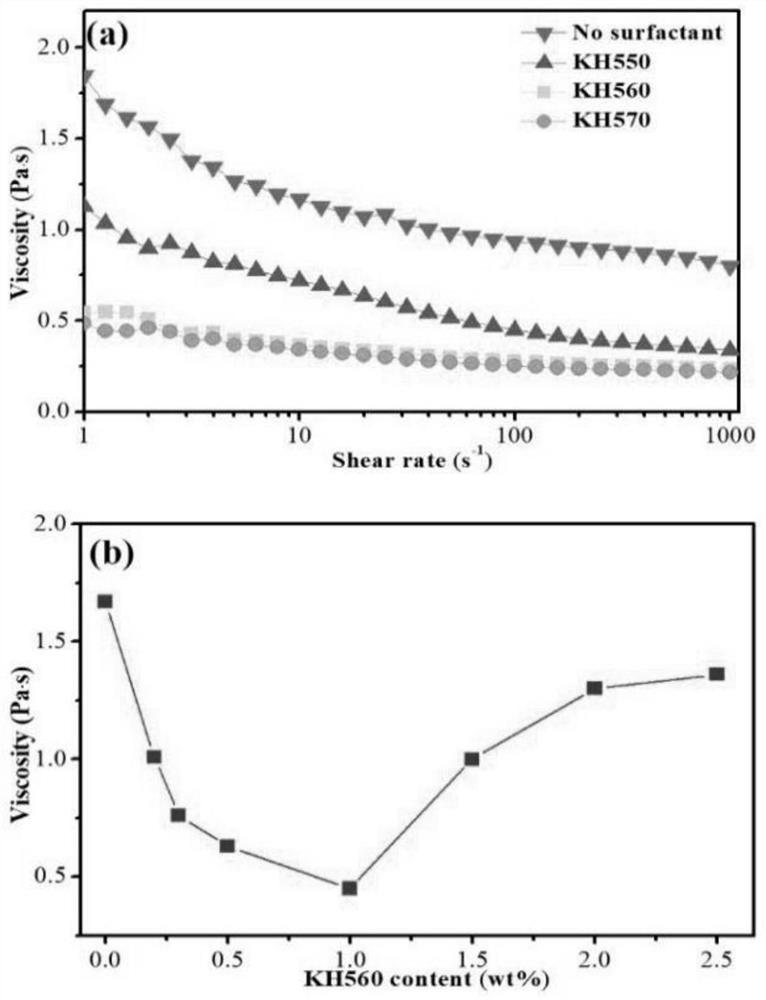

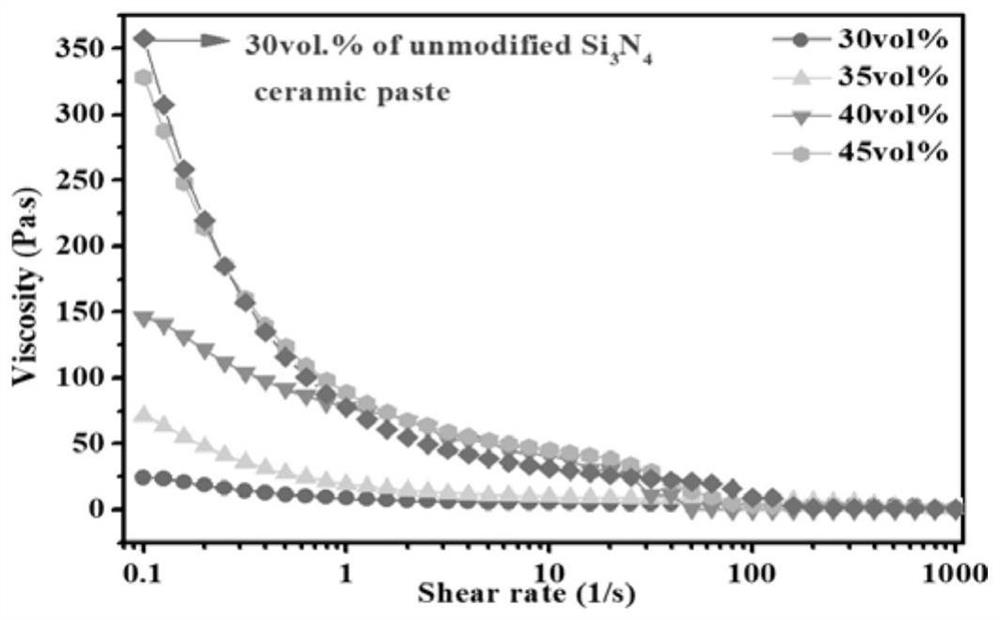

Preparation method of gradient layered structure silicon nitride ceramic

PendingCN113620717AReduce the refractive index differenceLow wettabilityHigh densityRefractive index

The invention discloses a preparation method of a gradient layered structure silicon nitride ceramic, the preparation method comprises the following steps: firstly, screening out a surface modifier capable of effectively reducing the refractive index difference of silicon nitride ceramic particles, and increasing the curing depth of the surface modifier; the applicant reveals a photocuring forming mechanism of the modified silicon nitride ceramic slurry by comparing rheological properties, dynamic stability, wettability and photocuring properties of the silicon nitride ceramic slurry before and after modification. By utilizing the mechanism, the rheological property, the dynamic stability, the wettability and the photocuring property of the silicon nitride ceramic slurry are improved, and the silicon nitride ceramic with high density, hardness and fracture toughness can be prepared.

Owner:萍乡旭材科技有限公司

Quick-drying building sealant composition

InactiveCN108977163ASmall smellImprove curing depthNon-macromolecular adhesive additivesOther chemical processesAdhesiveSealant

The invention relates to organic silicon resins, and discloses a quick-drying building sealant composition. The quick-drying building sealant composition comprises the following components in percentage by weight: a, 5-15% of an organic silicon resin GS-WKZM, b, 20-30% of an organic silicon resin GS-QL5000, c, 3-55 of a dimethicone diluent DMS-100, d, 20-25% of filler nano-calcium T1-101A, e, 20-30% of filler nano-calcium carbonate GS-TC80, f, 6-10% of GS-HS01 white cream, g, 2.5-5% of a crosslinking agent D-20, h, 0.1-0.2% of a curing agent S-210, i, 1-2% of an organic catalyst T-IBAY, j, 0.1-1% of a coupling agent, 0.01-0.02% of a catalyst T-12, l, 0.001-0.003% of a catalust T-440, and m, 0.5-2% of a free radical scavenger; and through kneading the components a to e by adoption of a vacuum kneading machine, rolling the kneaded components by a three-roller machine for twice, adding the component f by adoption of a planetary mixer, gradually adding the components g to h, I, j and l after uniformly mixing, adding the component n after the mixing, and carrying out sufficient mixing, the quick-drying building sealant composition is obtained. According to the quick-drying building sealant composition, the curing speeds of building adhesives are greatly improved and the cost is low.

Owner:惠展电子材料(上海)有限公司

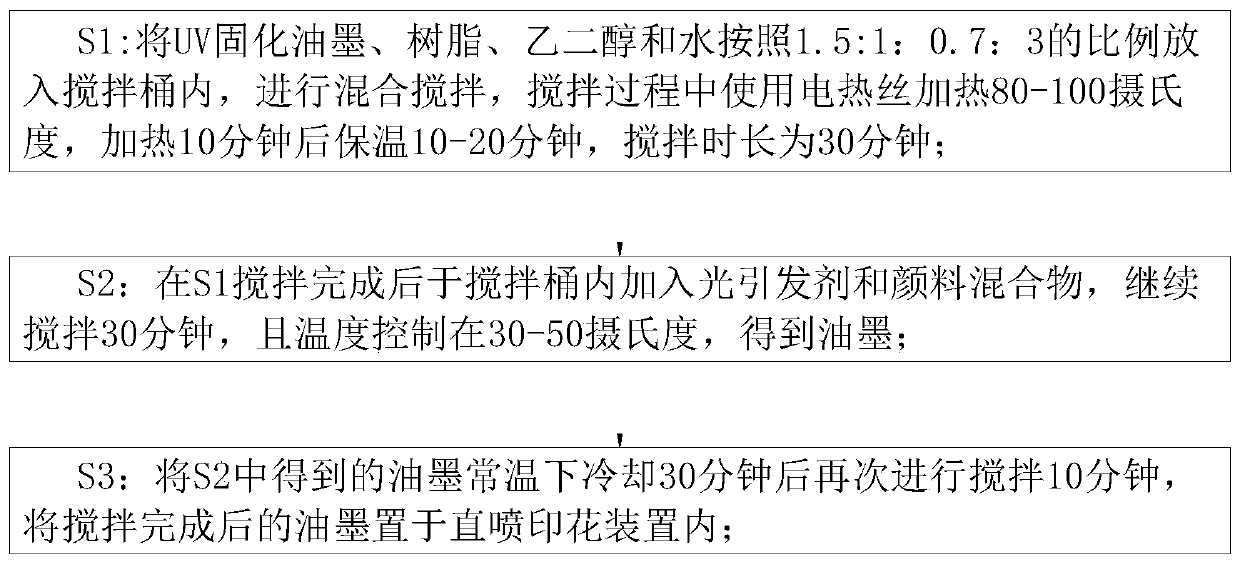

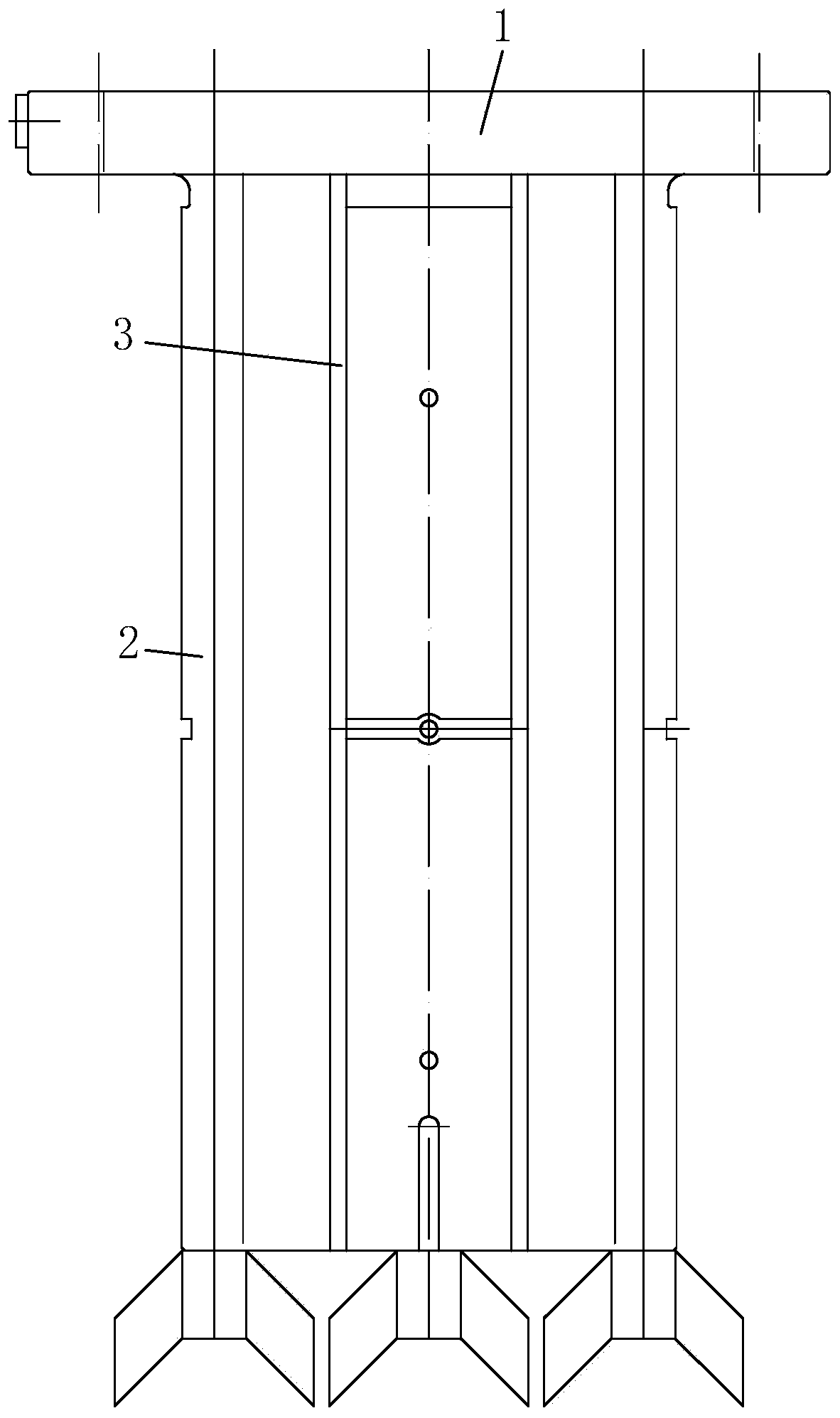

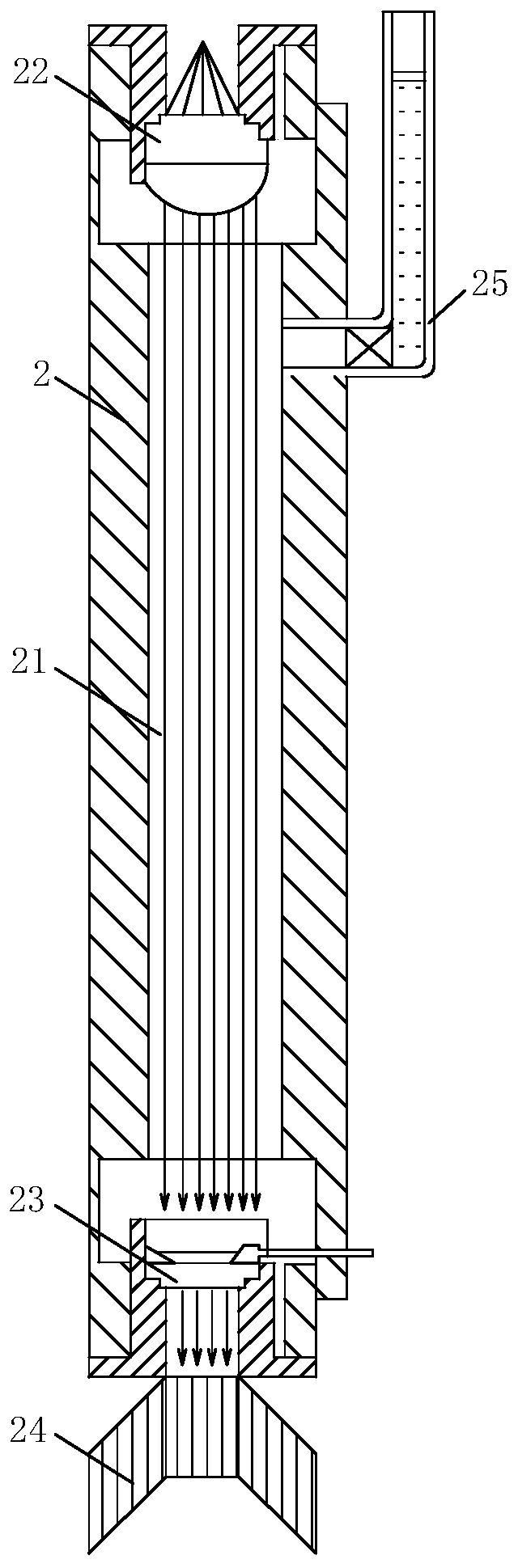

Direct-injection printing process adopting water-based UV cured ink

ActiveCN110466269ASignificant effect of coating curingImprove curing speedDuplicating/marking methodsInksWater basedUltraviolet

The invention relates to the field of printing processes, and specifically relates to a direct-injection printing process adopting water-based UV cured ink. The used direct-injection printing device comprises an installation seat, wherein ultraviolet lamps are fixedly installed around the installation seat separately; an ink injection pipe is connected into the installation seat in a sleeved manner; the bottom of the ink injection pipe penetrates through to reach the lower surface of the installation seat; and a lamp pipe is connected into each ultraviolet lamp in a sleeved manner. Through arrangement for an adjustor, a triangular plate is enabled to carry out closing action by rotating a drive gear, the drive gear is rotated by different degrees to adjust a luminous flux, so that passingultraviolet rays are ideally adjusted, influence on curing for a coating layer with a color is more obvious, and the curing speed and curing depth of the printing ink are increased; through arrangement for a light diffuser, conversion for the divergent light rays of a point light source to parallel light rays is facilitated; and in combination with a reflector, re-refraction for inclined light rays which pass through the interiors of the lamp pipes and are unbalanced due to the interference of mercury molecular reflection at the moment that the ultraviolet ray makes critical contact with ink to be cured, is facilitated.

Owner:绍兴宏强印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com