Organic silicon rubber waterproof adhesive and preparation method thereof

A technology of silicone rubber and waterproof glue, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of days or even longer time, long construction period of building waterproofing, long construction period, etc. The effect of reducing odor, improving bond strength and increasing curing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described below in combination with examples.

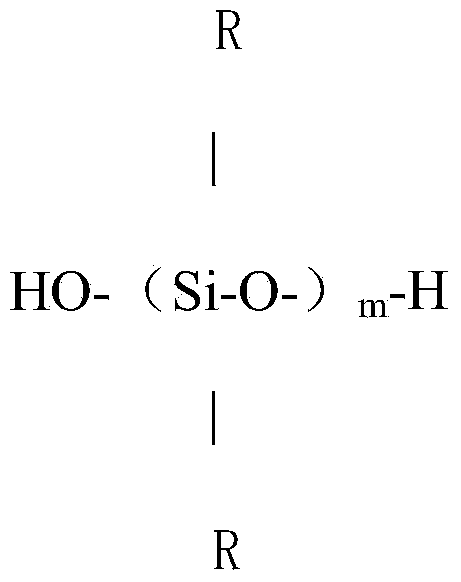

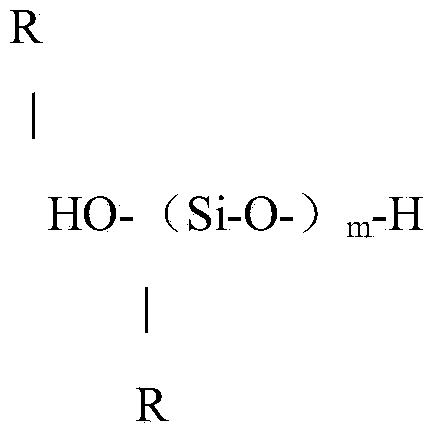

[0032] In the following examples, the viscosity of hydroxyl-terminated polysiloxane is 10000-30000cp; 2 The specific surface area is 150-250m 2 / g.

[0033] Hydroxy-terminated polysiloxane: Jiangxi Xinghuo Chemical Co., Ltd.

[0034] Vapor-phase SiO 2 : Wacker Germany

[0035] Colloidal calcium carbonate: Fujian Quanzhou Xufeng Powder Co., Ltd.

[0036] Zeolite molecular sieve: Shanghai Jiuzhou Molecular Sieve Co., Ltd.

[0037] Methyl tributylketoxime silane: Hubei Lantian Chemical Co., Ltd.

Embodiment 1

[0039] 40 parts of hydroxyl-terminated polydimethylsiloxane, reinforcing agent gas-phase method SiO 2 4 parts, 49 parts of calcium carbonate, 2.5 parts of hydrotalcite, respectively added to the mixer with a rotating speed of 600-800r / min and mixed at a mixing temperature of 70°C, and then pumped into a material tank with a pressure of ≤13.33kPa for degassing and degassing The air-filled rubber is continuously conveyed to the static mixer by the pump, and at the same time, 1 part of the cross-linking agent methyl tributylketoximosilane and the catalyst A mixture of 0.3 parts of dibutyltin laurate; the statically mixed rubber material continuously enters the twin-screw mixing extruder, and at the same time, the silane coupling agent N-β (aminoethyl)-γ is continuously added dropwise through the dripping port with pressure - 0.2 parts of aminopropyltrimethoxysilane and 2.5 parts of curing accelerator N,N-dimethylformamide; after the rubber material is fully mixed in a twin-screw ...

Embodiment 2

[0041] 20 parts of hydroxyl-terminated polymethylphenylsiloxane, reinforcing agent gas-phase method SiO 2 7 parts, 60 parts of quartz powder, and 5 parts of zeolite, respectively added to a stirrer with a rotation speed of 600-800r / min and mixed at a mixing temperature of 50°C, and then pumped into a material tank with a pressure of ≤13.33kPa for degassing and degassing The finished rubber is continuously conveyed to the static mixer by the pump, and at the same time, 3 parts of the cross-linking agent vinyl butanoneximosilane and the catalyst stannous octoate are continuously conveyed to the static mixer by the KRC kneader (horizontal closed continuous kneader) 0.8 parts of the mixture; the statically mixed rubber material continuously enters the twin-screw mixing extruder, and at the same time, 0.7 parts of the silane coupling agent γ-aminopropyltriethoxysilane is continuously added dropwise through the pressure drop port and solidified Accelerator N-methylformamide 3 parts;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com