High-efficiency packaging method for MWT assembly

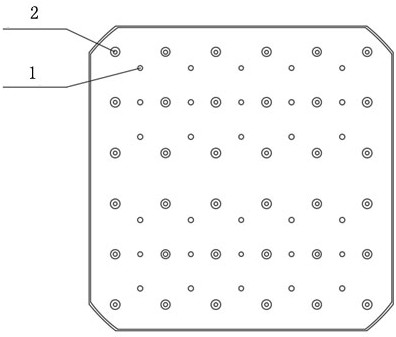

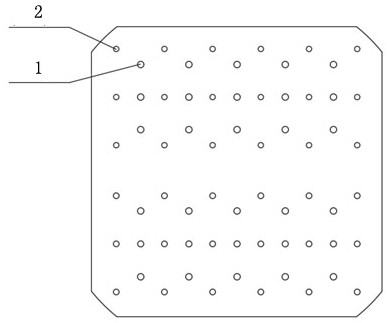

A packaging method and high-efficiency technology, applied in electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of high hole alignment accuracy, black stringing in the lamination process, poor spacing between chips, etc., to increase the curing depth, glue Effect of layer thickness reduction, increased current collection pathway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

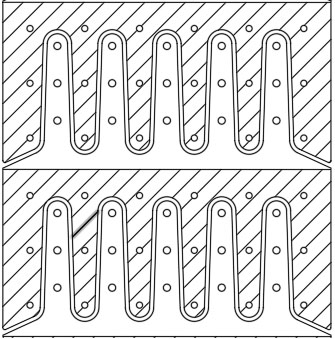

Method used

Image

Examples

Embodiment 1

[0040] Polyurethane thickness 25mm, oven temperature 80°C, oven time 2min, epoxy acrylic thickness 5mm, UV exposure time 30s, total thickness of adhesive layer 30mm, lamination temperature 138°C for one chamber, lamination time for one chamber 7min, two chambers The pressing temperature is 142°C, and the lamination time for one cavity is 7 minutes.

Embodiment 2

[0042] Polyurethane thickness 20mm, oven temperature 80°C, oven time 1min, epoxy acrylic thickness 10mm, UV light time 35s, total thickness of adhesive layer 30mm, lamination temperature 138°C for one cavity, lamination time for one cavity 7min, two-cavity layer The pressing temperature is 142°C, and the lamination time for one cavity is 7 minutes.

Embodiment 3

[0044] Polyurethane thickness 20mm, oven temperature 80°C, oven time 1min, epoxy acrylic thickness 15mm, UV exposure time 40s, total thickness of adhesive layer 30mm, lamination temperature 138°C for one chamber, lamination time for one chamber 7min, two chambers The pressing temperature is 142°C, and the lamination time for one cavity is 7 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com