Electromagnetic wave shielding material for FPC

A technology of shielding materials and electromagnetic waves, which is applied in the field of electromagnetic wave shielding materials for FPC, can solve the problems of disappearance and the decline of electromagnetic wave shielding machines, and achieve the effect of suppressing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

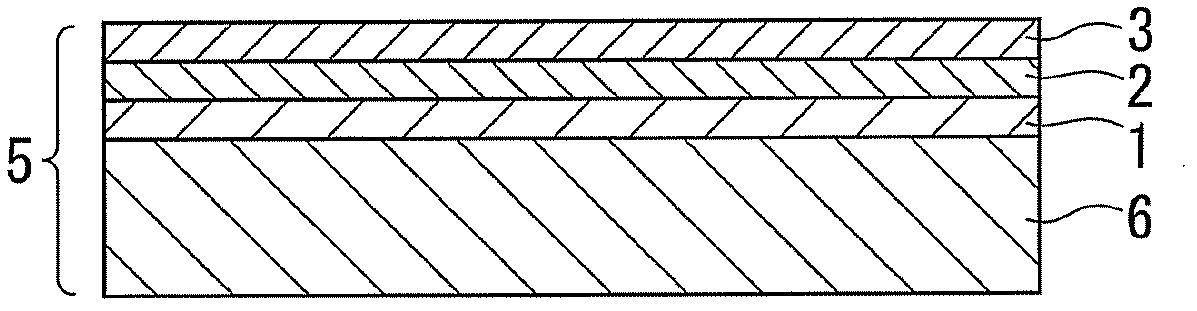

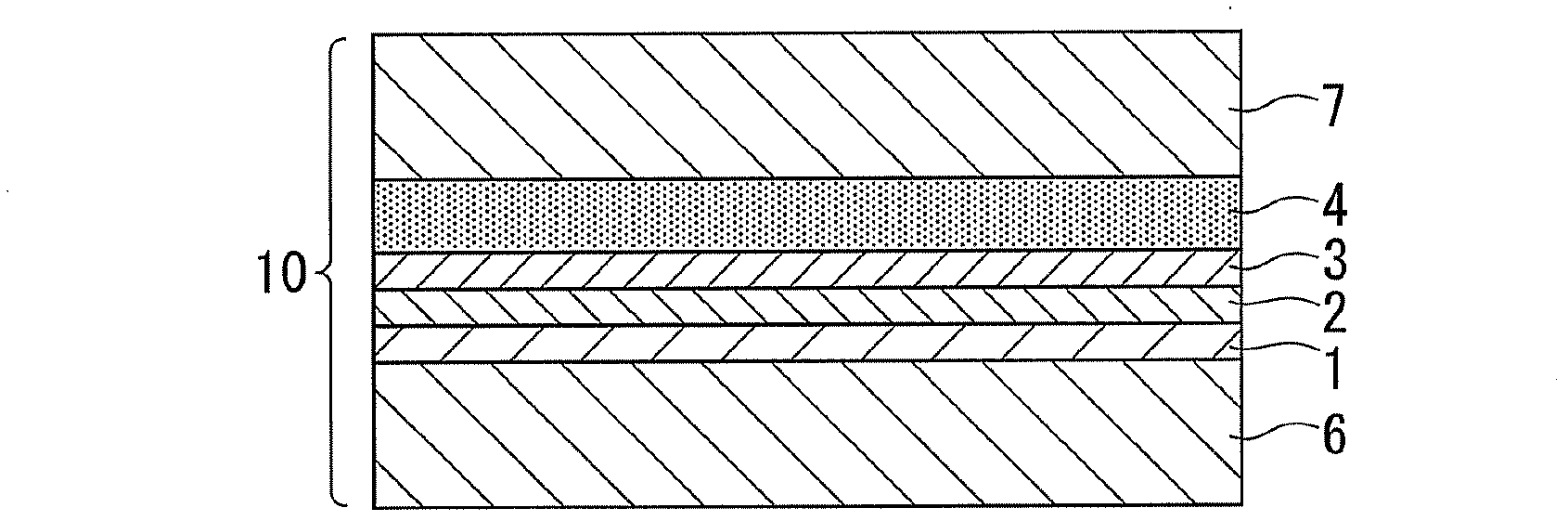

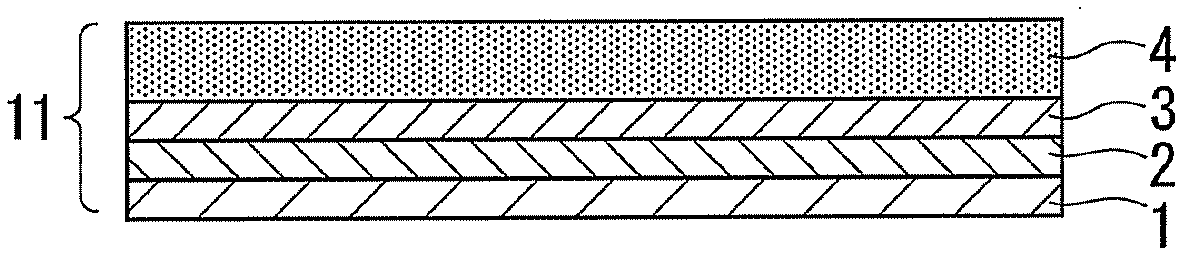

[0107] A polyethylene terephthalate (PET) film (manufactured by Toyobo Co., Ltd., product number: E5100) having a thickness of 50 μm was used as the support film 6 . On one side of the support film 6, a solvent-soluble polyimide coating liquid was cast-coated so that the thickness after drying became 4 μm, and dried to laminate a dielectric thin resin film. Substrate 1. On the formed base material 1, the paint for forming the adhesive bond layer 2 is applied so that the thickness after drying is 0.3 μm, and the adhesive bond layer 2 is laminated. Carbon black, which is a black pigment, is mixed with a polyester resin composition having a heat-resistant temperature of 260 to 280°C. On the adhesive layer 2, as a conductive filler, a conductive paste prepared by mixing silver particles with a primary average particle diameter of about 50 nm is used, and after drying, the thickness becomes 0.3 μm. It baked at 150 degreeC, the electroconductive paste layer 3 was formed, and the e...

Embodiment 2

[0109]A polyethylene terephthalate (PET) film (manufactured by Toyobo Co., Ltd., product number: E5100) having a thickness of 50 μm was used as the support film 6 . On one side of the support film 6, a solvent-soluble polyimide coating liquid was cast-coated so that the thickness after drying became 8 μm, dried, and a thin resin film made of a dielectric was laminated. Substrate 1. On the formed base material 1, the paint for forming the adhesive bond layer 2 is applied so that the thickness after drying is 0.3 μm, and the adhesive bond layer 2 is laminated. Carbon black, which is a black pigment, is mixed with a polyester resin composition having a heat-resistant temperature of 260 to 280°C. On the adhesive layer 2, as a conductive filler, a conductive paste prepared by mixing silver particles with a primary average particle diameter of about 50 nm is used, and after drying, the thickness becomes 0.3 μm. It baked at 150 degreeC, the electroconductive paste layer 3 was forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com