Backlight module

A backlight and light source technology, applied in the field of backlight modules, can solve the problems of large thickness of direct-lit backlight modules, inability to meet the needs and development trends of display thinning, and inability to apply thin LCDs, etc. The effect of high brightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

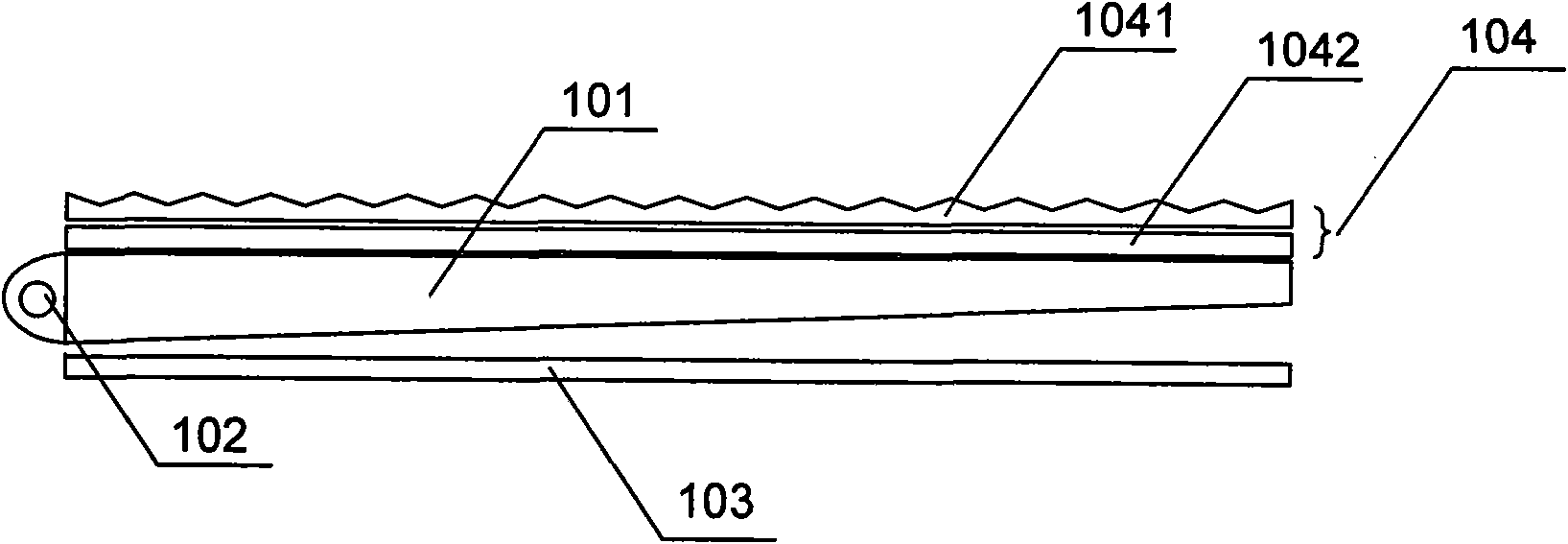

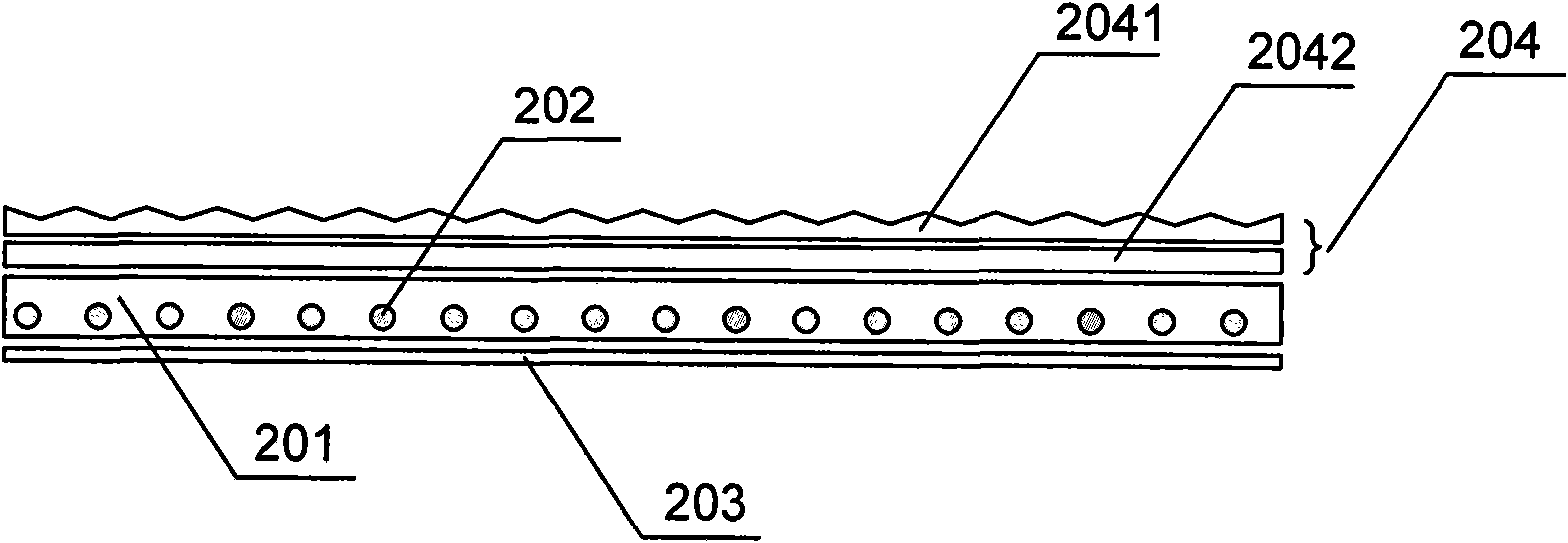

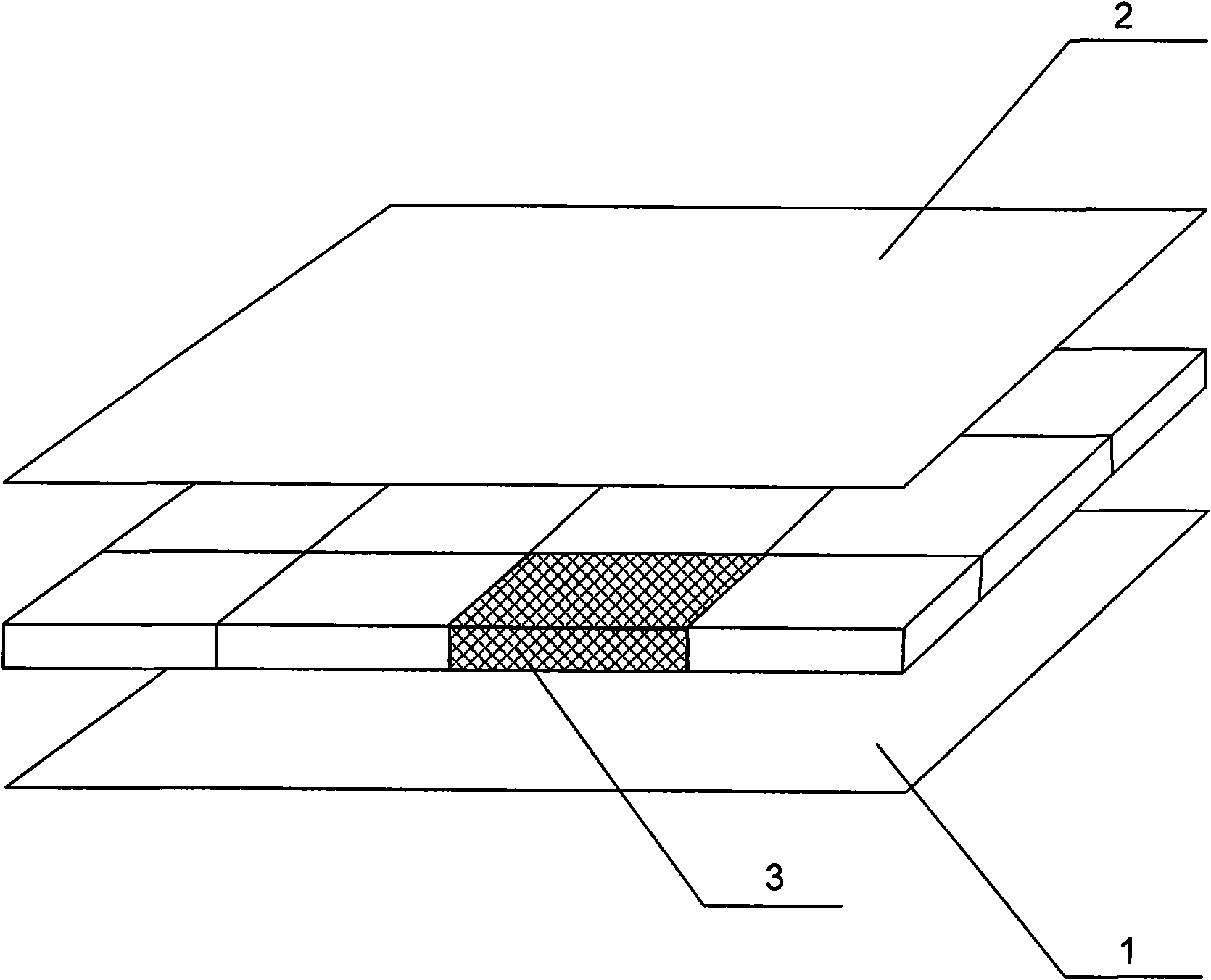

[0019] like image 3 As shown, it is a schematic structural diagram of an embodiment of the backlight module of the present invention, Figure 4 It is a cross-sectional view of an embodiment of the optical unit in the backlight module of the present invention. Please also see image 3 and Figure 4 , The backlight module provided by the embodiment of the present invention includes: a bottom reflection plate 1 and a light-emitting optical film group 2 , and one or more optical units 3 are arranged between the bottom reflection plate 1 and the light-emitting optical film group 2 . Each optical unit 3 includes a light guide plate 31 . The light guide plate 31 may be a polymethyl methacrylate (Polymethyl Methacrylate, hereinafter referred to as: PMMA) product or a polycarbonate (Polycarbonate, hereinafter referred to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com