Quick-drying building sealant composition

A technology of sealants and compositions, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of incapacity in the construction period, high prices of imported products, and the impact on the cost of construction enterprises, etc., to achieve fast curing speed, Simple construction and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

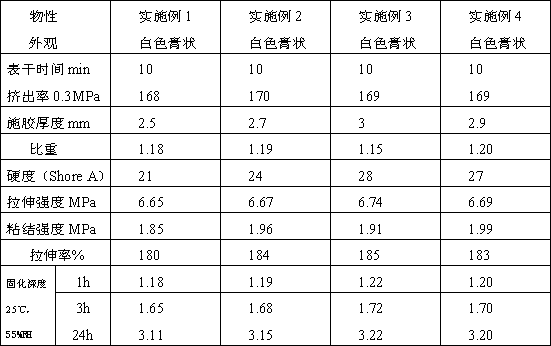

Examples

Embodiment 1

[0044] a, silicone resin GS-WKZM 14%,

[0045] b, silicone resin GS-QL5000 21.4%,

[0046] c, dimethicone thinner DMS-100 4%,

[0047] d, filler nano calcium T1-101A 24.4%,

[0048] e, filler nano calcium carbonate GS-TC80, 24%,

[0049] f, GS-HS01 white paste 6.2%,

[0050] g, crosslinking agent D-20 3.1%,

[0051] h, curing agent S-210 0.18%;

[0052] i, organic catalyst T-IBAY 1.2%,

[0053] j, coupling agent 0.5%

[0054] k, Catalyst T-12 0.017%,

[0055] l, Catalyst T-440 0.003%,

[0056] m, free radical scavenger 1%;

[0057] The stated percentages are by weight.

Embodiment 2

[0059] a, silicone resin GS-WKZM 10%,

[0060] b, silicone resin GS-QL5000 23.1%,

[0061] c, Dimethicone thinner DMS-100 3%,

[0062] d, filler nano calcium T1-101A 23%,

[0063] e, filler nano calcium carbonate GS-TC80, 25%,

[0064] f, GS-HS01 white paste 7.5%,

[0065] g, crosslinking agent D-20 4.5%,

[0066] h, curing agent S-210 0.10%;

[0067] i, organic catalyst T-IBAY 1.5%,

[0068] j, coupling agent 0.55%

[0069] k, Catalyst T-12 0.248%,

[0070] l, Catalyst T-440 0.002%,

[0071] m, free radical scavenger 1.5%;

[0072] The stated percentages are by weight.

Embodiment 3

[0074] a, silicone resin GS-WKZM 6%,

[0075] b, silicone resin GS-QL5000 28.15%,

[0076] c, Dimethicone thinner DMS-100 4.5%,

[0077] d, filler nano calcium T1-101A 20.5%,

[0078] e, filler nano calcium carbonate GS-TC80, 25%,

[0079] f, GS-HS01 white paste 8%,

[0080] g, crosslinking agent D-20 3.5%,

[0081] h, curing agent S-210 0.15%;

[0082] i, organic catalyst T-IBAY 1.5%,

[0083] j, coupling agent 0.595%

[0084] k, Catalyst T-12 0.595%,

[0085] l, Catalyst T-440 1.5%,

[0086] m, free radical scavenger 0.001%;

[0087] The stated percentages are by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com