A blue light curable ink composition for textiles and digital jet printing curing method thereof

A composition and textile technology, applied in the field of blue light curable ink composition for textiles and its digital jet printing and curing, can solve the problems of softness, elasticity, toughness and other wearing properties that are not suitable for flexible textiles, and can solve the problems of subsequent processing and consumption. Water energy consumption problem, good tensile strength, safe and efficient printing fabric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

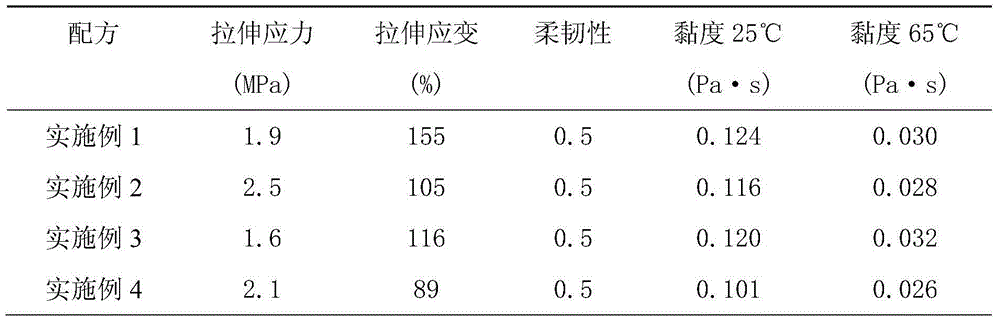

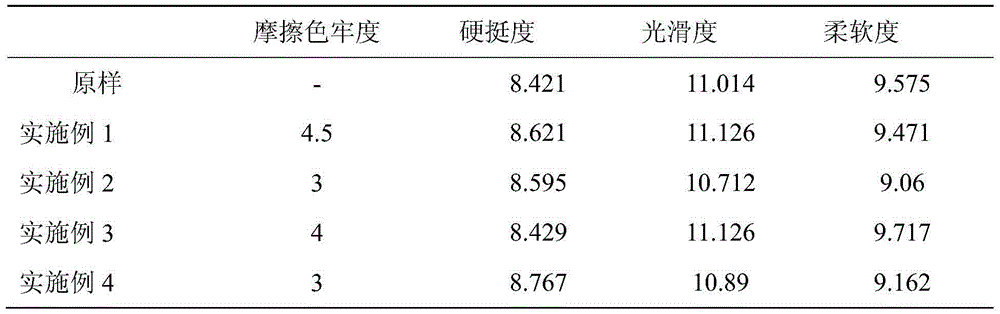

[0027] A kind of blue light curing digital inkjet printing ink composition for textiles, its each component is as follows:

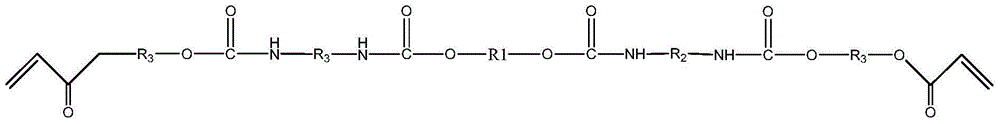

[0028] The first component, oligomer: urethane acrylate (self-made) 60wt%,

[0029] Monomer: butyl acrylate (Jiangsu Sanmu) 10wt%,

[0030] Monomer: SM612 (Jiangsu Sanmu) urethane monoacrylate 10wt%,

[0031] Monomer: isobornyl acrylate (Aladdin reagent) 20wt%;

[0032] The second component, based on the first component as 100%,

[0033] Blue light initiator: Chivacure534 (Taiwan Chi Titanium) 1wt%,

[0034] Activator: Chivacure OPD (Taiwan Chi Titanium) 1wt%,

[0035] Colorant: Disperse Turquoise Blue SGL (Zhejiang Longsheng) 2wt%,

[0036] Hyperdispersant Tech-5401 (Tiger polymer) 0.4wt%.

[0037] Among them, the blue light initiator Chivacure534 is bis-2,6-difluoro-3-pyrrole phenyl titanocene; the activator Chivacure OPD is isooctyl 4-dimethylaminobenzoate;

[0038] The viscosity of self-made urethane acrylate is lower than 1.0Pa·s, and commerc...

Embodiment 2

[0042] A kind of blue light curing digital inkjet printing ink composition for textiles, its each component is as follows:

[0043] The first component, oligomer: urethane acrylate (self-made) 60wt%,

[0044] Monomer: butyl acrylate (Jiangsu Sanmu) 10wt%,

[0045] Monomer: SR285 (Sartomer) tetrahydrofuran acrylate 10wt%,

[0046] Monomer: hydroxyethyl methacrylate (Aladdin reagent) 20wt%;

[0047] The second component, based on the first component as 100%,

[0048] Blue light initiator: Chivacure534 (Taiwan Chi Titanium) 1wt%,

[0049] Activator: Chivacure OPD (Taiwan Chi Titanium) 1wt%,

[0050] Colorant: 6505 Qinglianseyuan RNC (Hangzhou Xinchen Pigment) 1wt%,

[0051] Hyperdispersant Tech-5401 (Tiger polymer) 0.6wt%.

[0052] Among them, the blue light initiator Chivacure534 is bis-2,6-difluoro-3-pyrrole phenyl titanocene; the activator Chivacure OPD is isooctyl 4-dimethylaminobenzoate; the raw material and synthesis method of self-made polyurethane acrylate With emb...

Embodiment 3

[0055] A kind of blue light curing digital inkjet printing ink composition for textiles, its each component is as follows:

[0056] The first component, oligomer: urethane acrylate (self-made) 60wt%,

[0057] Monomer: Styrene (Tianjin Kemiou Chemical) 15wt%,

[0058] Monomer: tetrahydrofurfuryl acrylate (Shanghai TCI reagent) 5wt%,

[0059] Monomer: isooctyl acrylate (Aladdin reagent) 20wt%,

[0060] The second component, based on the first component as 100%,

[0061] Blue light initiator: camphorquinone (Sigma Aldrich) 0.5wt%,

[0062] Activator: IHT-PI EDB (Yingli Technology) 0.5wt%,

[0063] Colorant: Disperse Red 3B (Zhejiang Zhenguang Chemical Industry) 2wt%,

[0064] Hyperdispersant Tech-5401 (Tiger polymer) 0.4wt%.

[0065] Among them, the blue light initiator camphorquinone is 1,7,7-trimethyl-bicyclo[2.2.1]heptane-2,3-dione; the activator IHT-PIEDB is 4-dimethylaminobenzoic acid ethyl Ester; The raw material and synthetic method of self-made polyurethane acrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com