A coloring process for cotton fiber processing

A chemical fiber and cotton fiber technology is applied in the field of coloring technology for cotton fiber chemical fiber processing. Solubility, the effect of improving the suspension rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

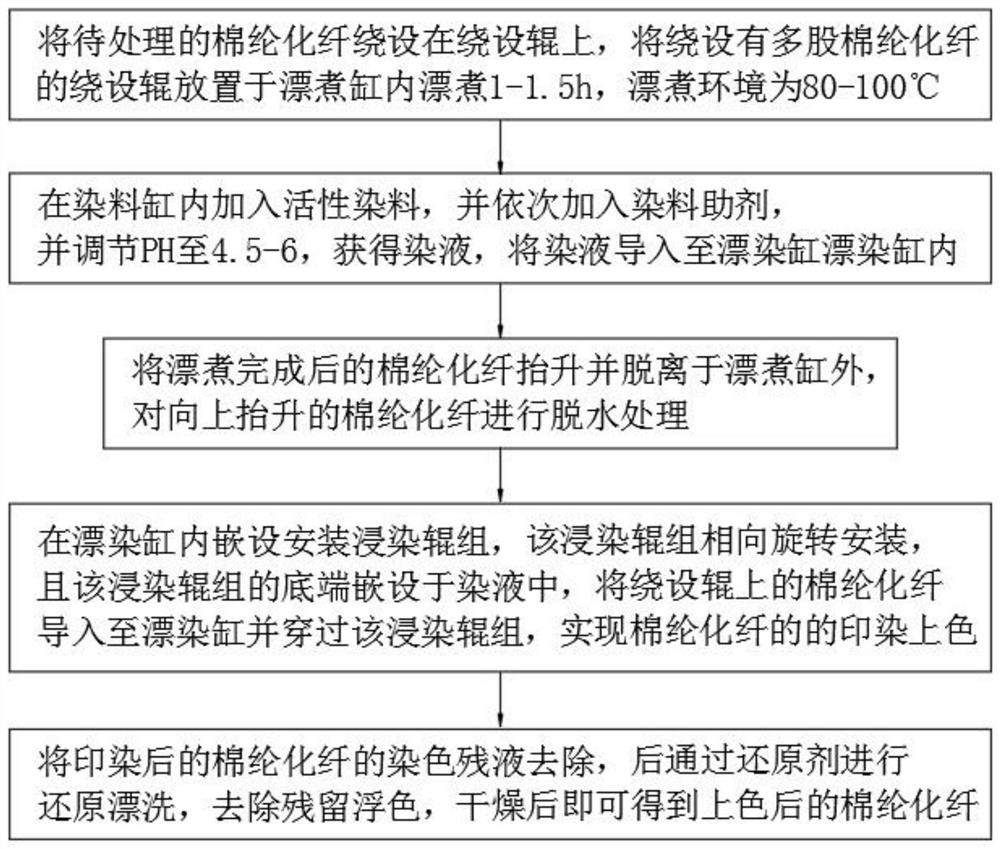

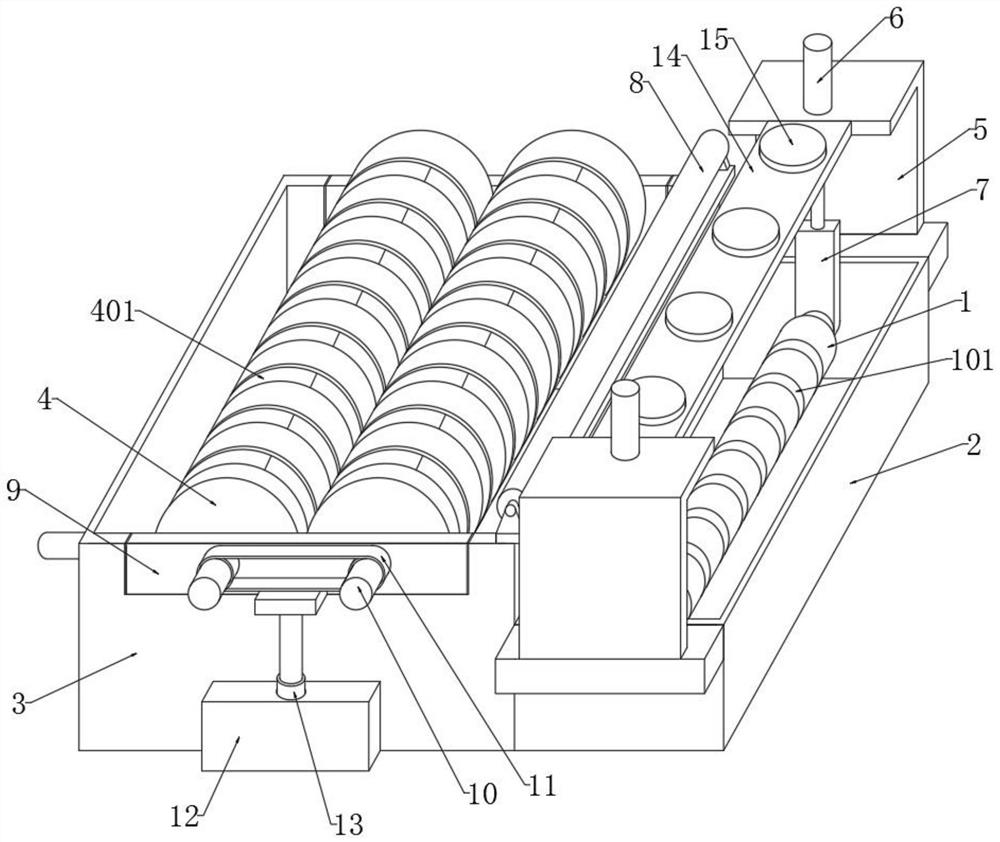

[0042] see figure 1 , a kind of coloring process for cotton fiber processing, comprising the following steps:

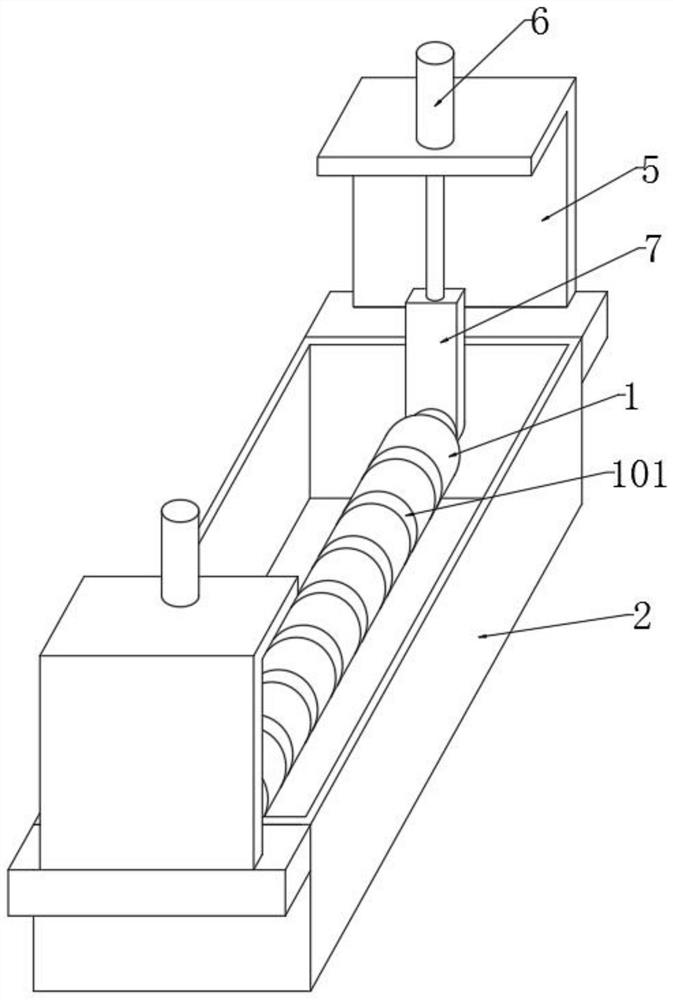

[0043] S1. Winding the cotton fiber to be treated on the winding roller 1, and placing the winding roller 1 wound with multiple strands of cotton fiber in the rinsing tank 2 for 1-1.5 hours. The rinsing environment is 80-100℃;

[0044] S2. Add reactive dyes to the dye vat, and add dye auxiliaries in turn, adjust the pH to 4.5-6, stir for 0.5-1h, and maintain a high temperature environment of 100-120°C to obtain dyeing liquor, which is introduced into the bleaching and dyeing In cylinder bleaching and dyeing cylinder 3;

[0045] S3. Elevate the cotton fiber chemical fiber after scouring in S1 and separate it from the bleaching tank 2, and perform dehydration treatment on the raised cotton fiber chemical fiber;

[0046] S4. Embed and install the exhaust dyeing roller group 4 in the bleaching and dyeing vat 3, the exhaust dyeing roller group 4 is installed in opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com