Waterless reductive dyeing process

A process and dye technology, applied in the field of anhydrous reductive dyeing process, can solve the problems of environmental air pollution, printing and dyeing process unfavorable to national environmental protection, high pollutant concentration, etc., and achieve high coloring rate, excellent economic benefits, and fewer cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

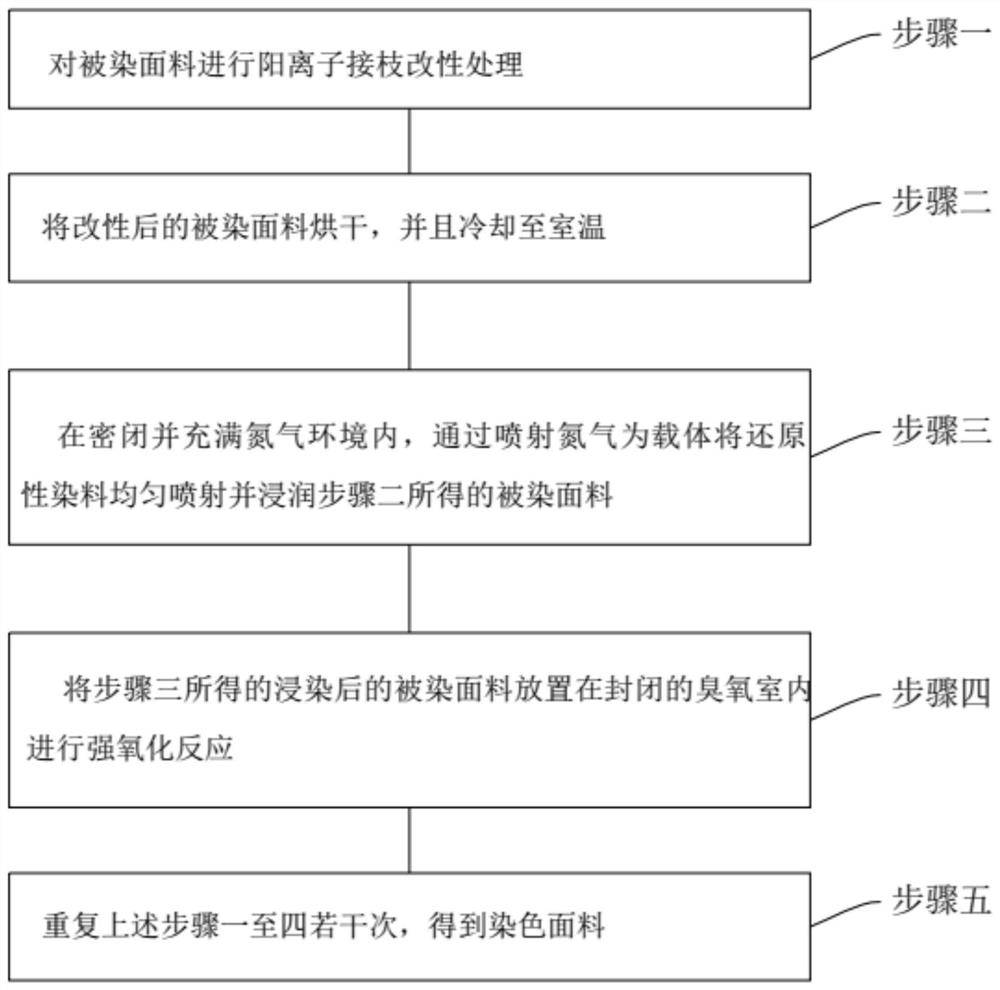

[0023] refer to figure 1 , taking cotton yarn as an example, it needs to be dyed with vat dyes such as indigo in order to make cotton yarn denim. The specific steps are as follows:

[0024] Step 1. Carry out cationic graft modification treatment on the dyed fabric, that is, cotton yarn, specifically soaking the cotton yarn in a polymer cationic modifier for 30 minutes; the cationic modifier adopts a cationic quaternary ammonium salt polymer, which is Compounds with reactive functional groups are mainly used in the new dyeing process of cellulose fibers for garment coatings and dyeing in the same bath with direct and reactive dyes. Therefore, the use of cationic grafting modification in this scheme is mainly to increase the color uptake rate of dyeing.

[0025] Step 2, raising the modified dyed fabric to 80 degrees Celsius for drying treatment, drying for 10 minutes, cooling to room temperature after drying, and then completing the pretreatment of material preparation. The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com