Ceramic material for photocuring forming as well as emulsion coating preparation method and application of ceramic material

A ceramic material and light-curing technology, which is applied in the field of ceramic materials, can solve the problems of low curing thickness of a single layer of ceramic slurry, influence on the performance of final formed ceramics, and large difference in refractive index of photosensitive resins, etc., so as to achieve short preparation cycle and reduce Absorption or scattering, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

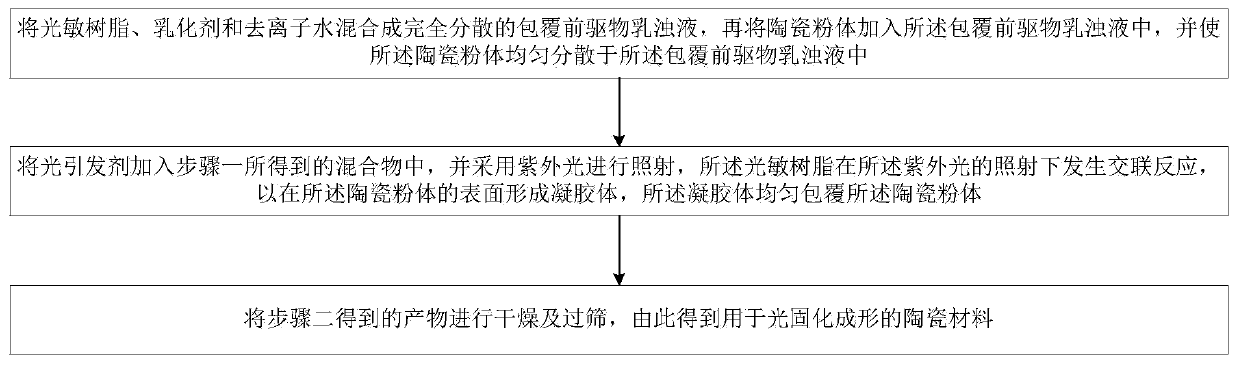

[0028] Specifically, the method for preparing the emulsion coating of the ceramic material for photocuring molding mainly includes the following steps:

[0029] Step 1: Mix the photosensitive resin, emulsifier and deionized water into a completely dispersed coating precursor emulsion, then add ceramic powder into the coating precursor emulsion, and make the ceramic powder uniformly dispersed in the coating precursor emulsion.

[0030] Specifically, the photosensitive resin, emulsifier and deionized water are mixed into a completely dispersed coating precursor emulsion by a mixing and stirring method, and then the ceramic powder is added to the coating precursor emulsion and stirring is continued.

[0031] In this embodiment, the mixing and stirring method includes one or both of magnetic stirring and mechanical stirring; wherein, the rotational speed used for the magnetic stirring is 500-3000 rpm; the rotational speed used for the mechanical stirring is 300-2000 rpm; The phot...

Embodiment 1

[0040] The preparation method for the emulsion coating of the ceramic material for photocuring and forming provided by the embodiment 1 of the present invention mainly includes the following steps:

[0041] (1) The magnetic stirrer stirs and mixes hydroxyethyl methacrylate, deionized water and alkylphenol polyoxyethylene ether at a rotating speed of 500rpm to form a hydroxyethyl methacrylate-deionized water emulsified solution, and then the silicon nitride ceramic The powder is added to the hydroxyethyl methacrylate-deionized water emulsified solution.

[0042] Wherein, the concentration of the hydroxyethyl methacrylate in the hydroxyethyl methacrylate-deionized water emulsified solution is 1 g / L; the alkane in the hydroxyethyl methacrylate-deionized water emulsified solution The concentration of phenol polyoxyethylene ether is 1 g / L; the particle size of the silicon nitride ceramic powder is 0.1 μm, and the silicon nitride ceramic powder is emulsified with the hydroxyethyl me...

Embodiment 2

[0046] The preparation method for the emulsion coating of the ceramic material for photocuring and forming provided by the embodiment 2 of the present invention mainly includes the following steps:

[0047] (1) Trimethylolpropane triacrylate, deionized water and alkylphenol polyoxyethylene ether are stirred and mixed into a trimethylolpropane triacrylate-deionized water emulsified solution with a magnetic stirrer at a rotating speed of 3000 rpm, and then the Silicon carbide ceramic powder is added to the trimethylolpropane triacrylate-deionized water emulsified solution.

[0048] Wherein, the concentration of the trimethylolpropane triacrylate in the trimethylolpropane triacrylate-deionized water emulsified solution is 5 g / L; the trimethylolpropane triacrylate-deionized water The concentration of the alkylphenol polyoxyethylene ether in the emulsified solution is 2g / L; the particle size of the silicon nitride ceramic powder is 100 μm, and the silicon nitride ceramic powder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com