Organic light emission diode and preparation method therefor

An electroluminescent device and luminescent technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low light output and low light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

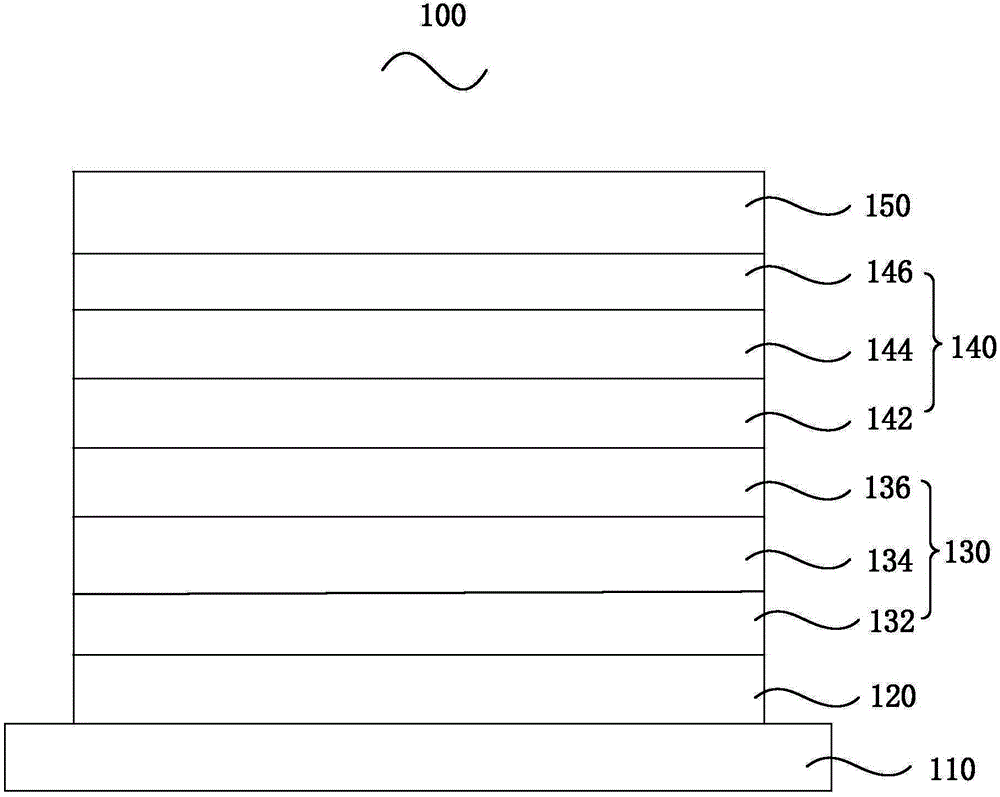

preparation example Construction

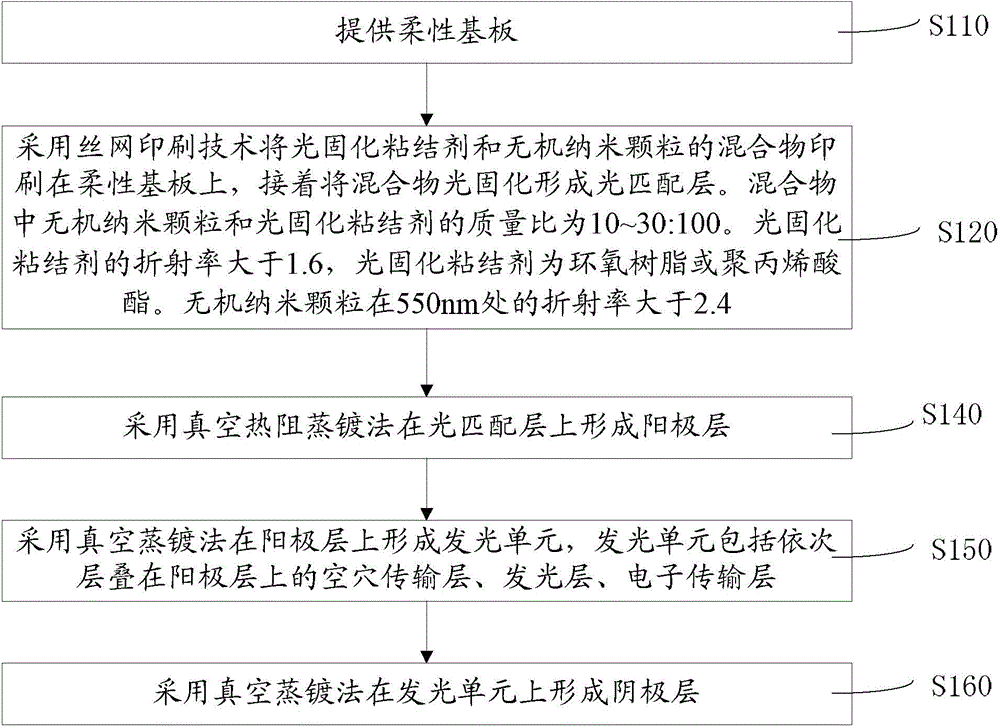

[0051] Such as figure 2 As shown, the preparation method of the above-mentioned organic electroluminescent device of one embodiment includes the following steps:

[0052] S110, providing a flexible substrate.

[0053] Flexible substrates are cleaned before use.

[0054] The flexible substrate can be a polymer transparent film. For example, polyethylene terephthalate (polyethylene terephthalate, PET) film, polyether sulfone resin (Poly (ether sulfones), PES) film, polycarbonate (Polycarbonate, PC) film or polyimide (Polyimide , PI) films, etc. The thickness of the flexible substrate may be 0.1mm˜0.5mm.

[0055] S120. Print the mixture of photocurable binder and inorganic nanoparticles on the flexible substrate by screen printing technology, and then photocure the mixture to form an optical matching layer. The mass ratio of the inorganic nanoparticles and the light-curing binder in the mixture is 10-30:100. The refractive index of the light-curing adhesive is greater than...

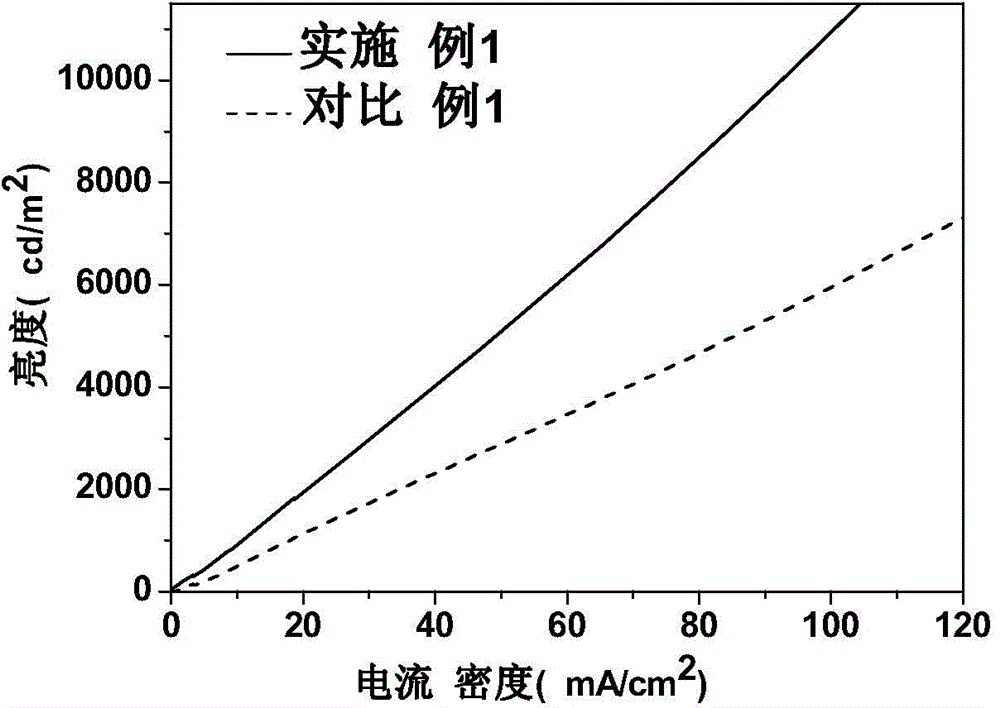

Embodiment 1

[0076] A PET substrate with a thickness of 0.1 mm is provided and cleaned.

[0077] Mix PbS with epoxy resin at a mass ratio of 10:100. The particle size of PbS is 5 nm. Then ultrasonic vibration was dispersed for 1 hour to obtain a mixture. Then, the above mixture was printed on the surface of the flexible substrate by using screen printing technology with a mesh number of 1000 to form a film with a thickness of 20 μm. Then adopt photocuring method to cure the above thin film to form an optical matching layer.

[0078] A first dielectric layer is formed on the optical matching layer by vacuum thermal resistance evaporation method. The material of the first dielectric layer is WO 3 , with a thickness of 40nm. A metal layer is formed on the first dielectric layer by vacuum thermal resistance evaporation method. The material of the metal layer is Ag, and the thickness is 18nm. A second dielectric layer is formed on the metal layer by vacuum thermal resistance evaporation ...

Embodiment 2

[0084] Provide a PES substrate with a thickness of 0.5mm and clean it.

[0085] Mix ZnS with polyacrylate at a mass ratio of 20:100. The particle diameter of ZnS is 25 nm. Then ultrasonic vibration was dispersed for 5 hours to obtain a mixture. Then, the above mixture was printed on the surface of the flexible substrate by using screen printing technology with a mesh number of 600 to form a film with a thickness of 100 μm. Then adopt photocuring method to cure the above thin film to form an optical matching layer.

[0086] A first dielectric layer is formed on the optical matching layer by vacuum thermal resistance evaporation method. The material of the first dielectric layer is MoO 3 layer with a thickness of 80 nm. A metal layer is formed on the first dielectric layer by vacuum thermal resistance evaporation method. The material of the metal layer is Al, and the thickness is 30nm. A second dielectric layer is formed on the metal layer by vacuum thermal resistance eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com