Dual-cured ceramic material for additive manufacturing and preparation method and application of dual-cured ceramic material

A ceramic material and additive manufacturing technology, applied in the field of additive manufacturing materials, which can solve the problems of difficult-to-solidify ceramic materials, such as difficulty in printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

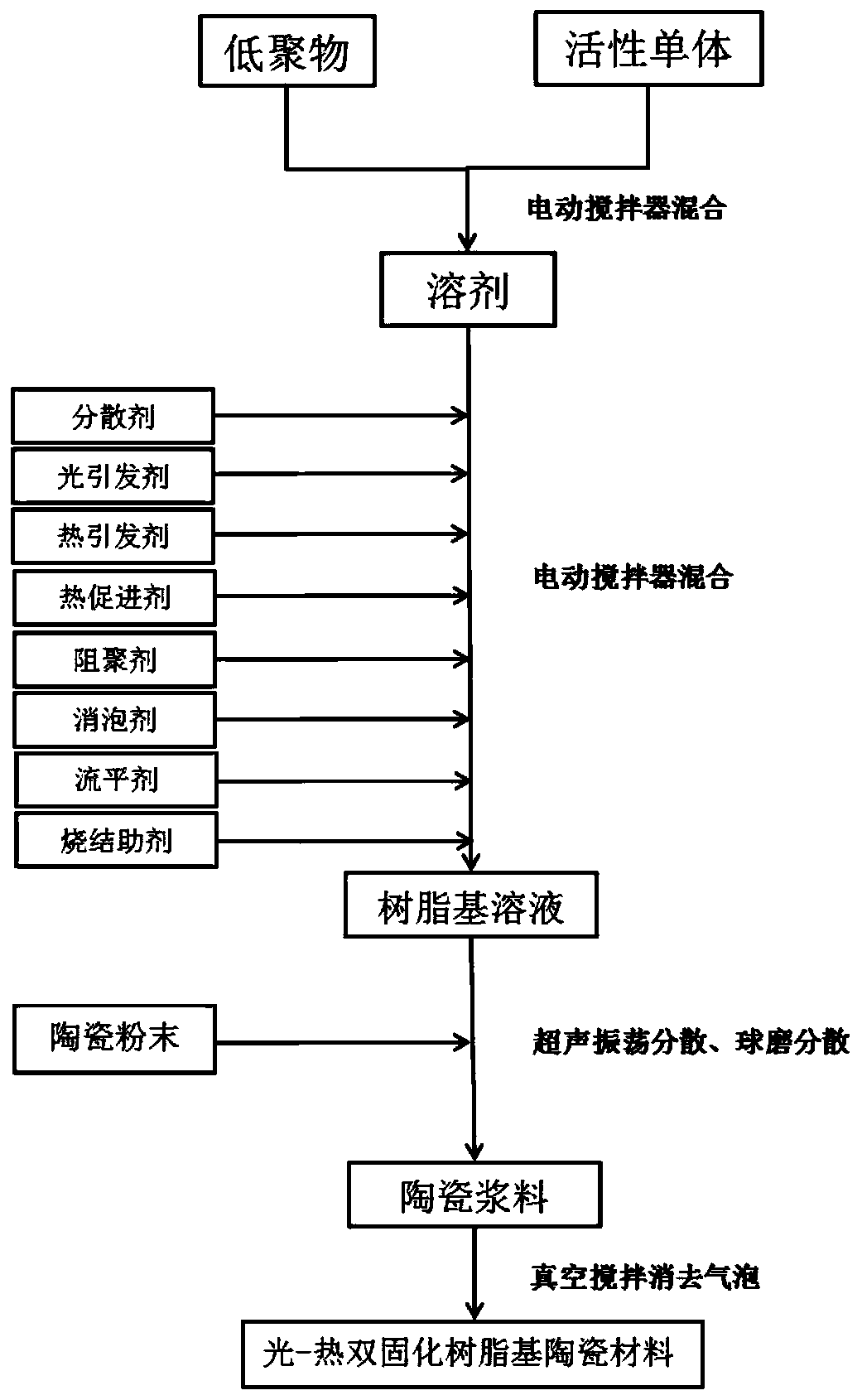

Method used

Image

Examples

experiment example 1

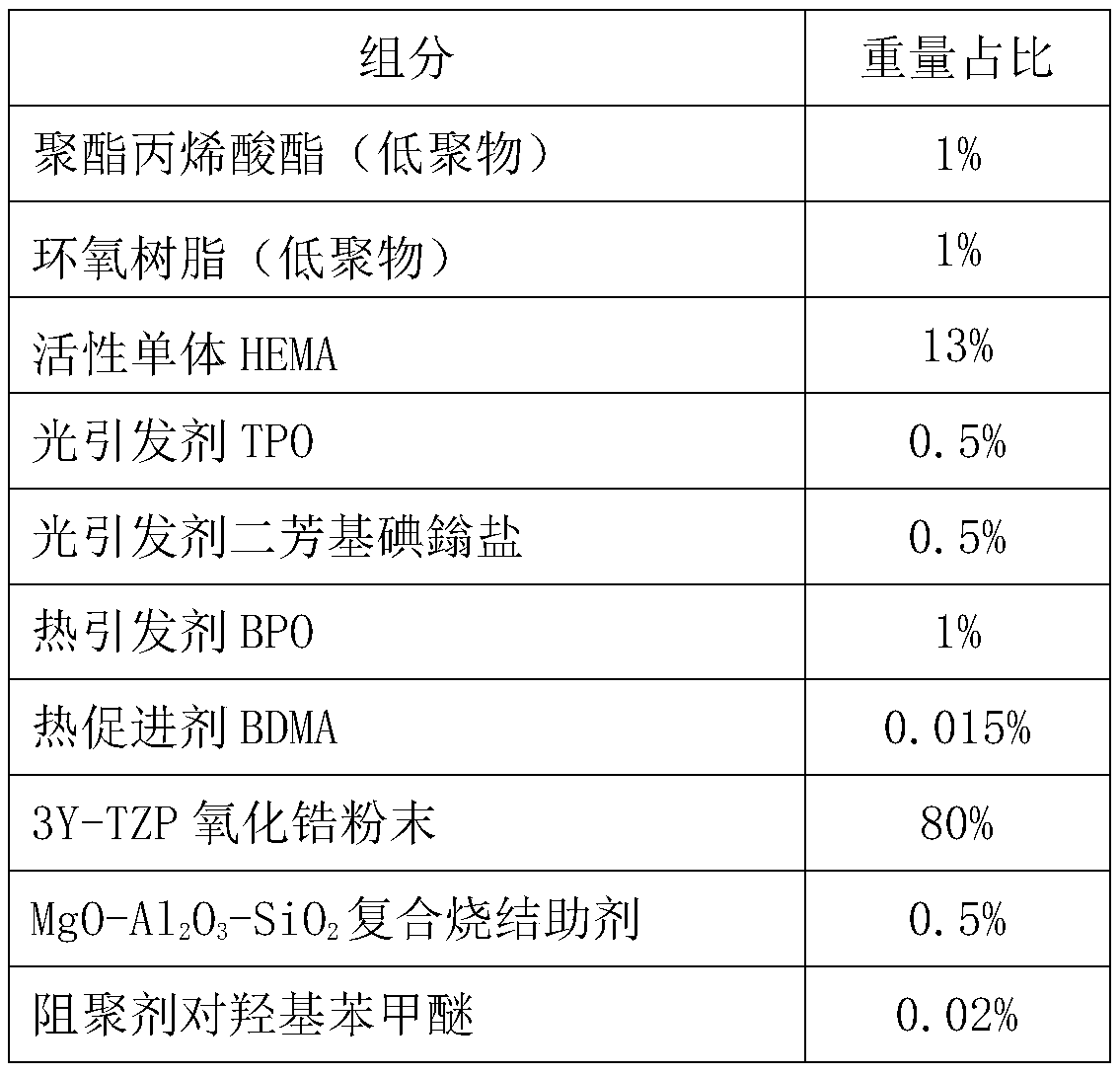

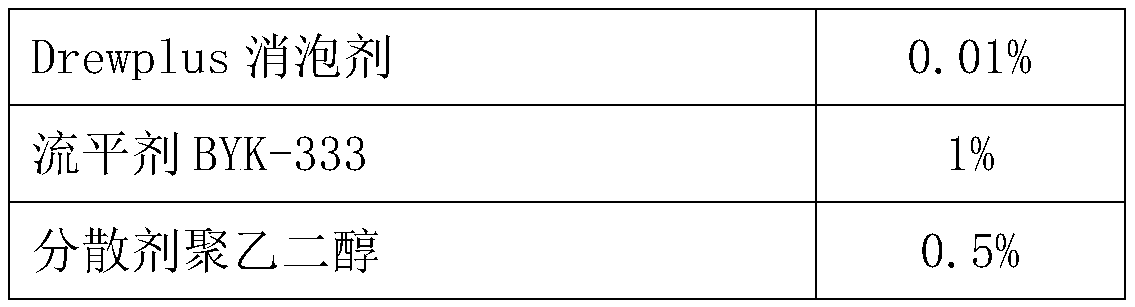

[0043] Experimental Example 1 used the components in weight proportion shown in Table 1.

[0044] Table 1 Components used in Experimental Example 1

[0045]

[0046]

[0047] The specific preparation method of Experimental Example 1 is as follows.

[0048] Put urethane acrylate, epoxy resin, and active monomer HEMA (hydroxyethyl methacrylate) into a beaker; use an electric stirrer to disperse, set the speed at 200r / min, and stir for 20min to obtain a uniformly mixed solvent.

[0049] Add dispersant polyethylene glycol, photoinitiator TPO, photoinitiator diaryliodonium salt, thermal initiator BPO, thermal accelerator BDMA, polymerization inhibitor p-hydroxyanisole, Drewplus disinfectant to the solvent at room temperature Foaming agent, leveling agent BYK-333, MgO-Al 2 o 3 -SiO2 Composite sintering aids were dispersed for 30 minutes with an electric stirrer at a speed of 200 r / min to obtain a resin-based solution. This step should be performed in the dark.

[0050] Pu...

experiment example 2

[0054] Experimental Example 2 used the components in weight proportion shown in Table 2.

[0055] Table 2 Components used in Experimental Example 2

[0056]

[0057]

[0058] The specific preparation method of Experimental Example 2 is the same as that of Experimental Example 1.

experiment example 3

[0060] Experimental Example 3 used the components in weight proportion shown in Table 3.

[0061] Table 3 Components used in Experimental Example 3

[0062] Element Weight ratio urethane acrylate 1% active monomer TEGDMA 30% Photoinitiator 819 1% Thermal curing initiator BPO 5% Thermal Accelerator N,N-Dimethylaniline 1% Leveling agent BYK-358 0.1% CaO-Al 2 o 3 -SiO 2 Composite sintering aid

[0063] The specific preparation method of Experimental Example 3 is the same as that of Experimental Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com