Reactive hot melt adhesive composition as well as preparation method and application thereof

A technology of hot-melt adhesives and compositions, applied in the direction of adhesive types, polyurea/polyurethane adhesives, polymer adhesive additives, etc., to achieve the effect of increasing the reaction speed and the depth of colloid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

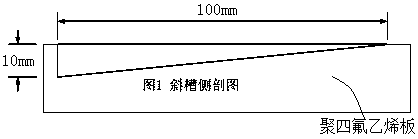

Image

Examples

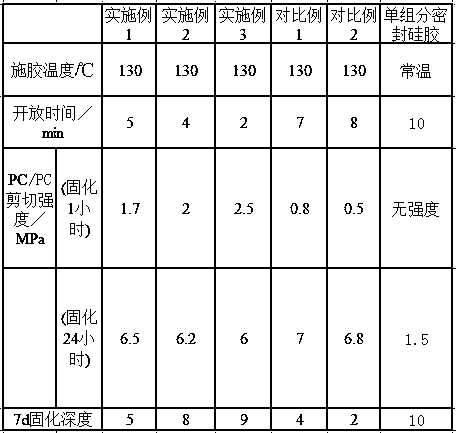

Embodiment 1

[0042] Take 80g of isocyanate prepolymer A, 10g of tackifying resin, 1g of fumed silica (R972), 9g of silane-modified silicone resin D, and 0.02g of toluenesulfonyl isocyanate into the reaction kettle. At 80°C, vacuumize and mix for 60min. Add 0.10g of γ-aminopropyltrimethoxysilane (KH-540), a mixture of stannous octoate and 2'2-dimorpholinodiethyl ether (1:1) 0.1g. After vacuum mixing for 15 minutes. Vacuum defoaming for 30min. Glue out. Pour into the mold to measure the curing depth and shear strength test.

Embodiment 2

[0044] Take 70g of isocyanate prepolymer A, 10g of tackifying resin, 1g of fumed silica (R972), 19g of silane-modified silicone resin D, and 0.02g of toluenesulfonyl isocyanate into the reaction kettle. At 80°C, vacuumize and mix for 60min. Add 0.20g of γ-aminopropyltrimethoxysilane (KH-540), a mixture of stannous octoate and 2'2-dimorpholinodiethyl ether (1:1) 0.1g. After vacuum mixing for 15 minutes. Vacuum defoaming for 30min. Glue out. Pour into the mold to measure the curing depth and shear strength test.

Embodiment 3

[0046] Take 60g of isocyanate prepolymer A, 10g of tackifying resin, 1g of fumed silica (R972), 29g of silane-modified silicone resin D, and 0.02g of toluenesulfonyl isocyanate into the reaction kettle. At 80°C, vacuumize and mix for 60min. Add 0.30g of γ-aminopropyltrimethoxysilane (KH-540), a mixture of stannous octoate and 2'2-dimorpholinodiethyl ether (1:1) 0.1g. After vacuum mixing for 15 minutes. Vacuum defoaming for 30min. Glue out. Pour into the mold to measure the curing depth and shear strength test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com