Silicon carbide ceramic paste for photocuring and preparation method thereof

A silicon carbide ceramic and light curing technology, applied in the direction of additive processing, can solve problems such as unfavorable sintering and reduce the solid content of paste, and achieve the effect of improving printing efficiency, increasing curing depth and increasing solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

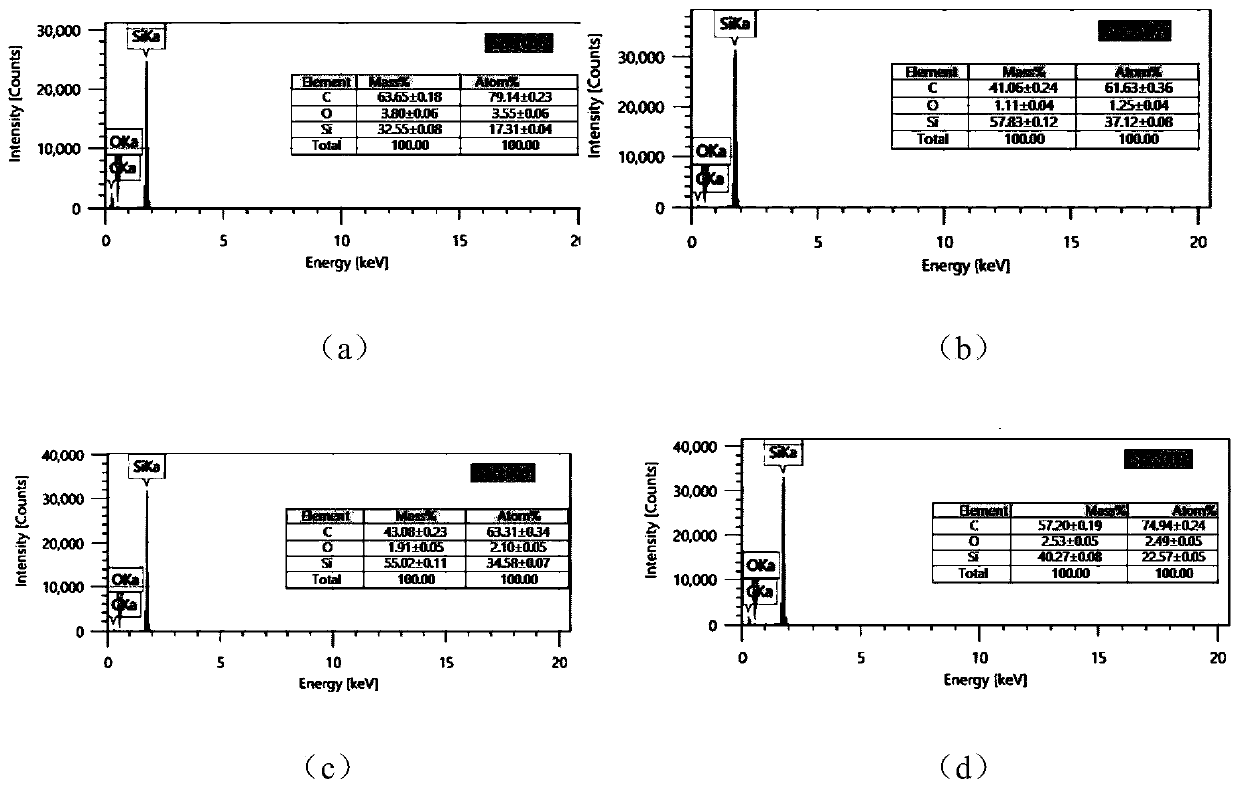

[0053] Step 1: Coating a layer of SiO on the surface of spherical SiC powder with d50=0.4um and spherical SiC powder with d50=2.5um by CVD method 2 , SiO 2 The thickness of the layer is 8 nm.

[0054] Step 2, put the two coated powders into the ball mill, wherein the SiC powder with d50=0.4um accounts for 20% by mass, the balance is SiC powder with d50=2.5um, and the added SiC powder is 1% by mass The stearic acid was ball milled for 12 hours at a ball milling speed of 360 r / min, and SiC mixed powder was formed after ball milling.

[0055] Step 3, weighing 100g of SiC mixed powder, 1g of dispersant, 34.69g of monomer, 3g of compatibilizer and 0.69g of photoinitiator respectively, wherein the SiC mixed powder is sieved through a 100 mesh screen after drying; the content of compatibilizer is SiC mixed powder 3wt%, dispersant content is 1wt% of SiC mixed powder, monomer content is 34.69wt% of SiC mixed powder, photoinitiator content is 2wt% of monomer mass; Compatibilizer is st...

Embodiment 2

[0063] Step 1: Coating a layer of SiO on the surface of spherical SiC powder with d50=0.4um and spherical SiC powder with d50=2.5um by CVD method 2 , SiO 2 The thickness of the layer is 8 nm.

[0064] Step 2, put the coated two powders into the ball mill, where the mass of SiC powder with d50=0.4um accounts for 30%, the balance is SiC powder with d50=2.5um, and the mass of SiC powder added is 1% The stearic acid was ball milled for 12 hours at a ball milling speed of 360 r / min, and SiC mixed powder was formed after ball milling.

[0065] Step 3, weigh 100g of SiC mixed powder, 0.7g of dispersant, 23.1g of monomer, 2.5g of compatibilizer and 0.46g of photoinitiator, wherein the SiC mixed powder is sieved through a 100 mesh screen after drying; The content is 2.5wt% of the SiC mixed powder, the dispersant content is 0.7wt% of the SiC mixed powder, the monomer content is 23.1wt% of the SiC mixed powder, and the photoinitiator content is 2wt% of the monomer mass; the compatibili...

Embodiment 3

[0069] Step 1: Coating a layer of SiO on the surface of spherical SiC powder with d50=0.4um and spherical SiC powder with d50=2.5um by CVD method 2 , SiO 2 The thickness of the layer is 10 nm.

[0070] Step 2, put the two coated powders into the ball mill, wherein the SiC powder with d50=0.4um accounts for 40% of the mass, and the balance is SiC powder with d50=2.5um, and the added SiC powder is 1% by mass The stearic acid was ball milled for 12 hours at a ball milling speed of 360 r / min, and SiC mixed powder was formed after ball milling.

[0071] Step 3, weigh 100g of SiC mixed powder, 0.6g of dispersant, 30g of monomer, 1.5g of compatibilizer and 0.66g of photoinitiator, wherein the SiC mixed powder is sieved through a 100 mesh screen after drying; the content of compatibilizer SiC mixed powder 1.5wt%, dispersant content is 0.6wt% of SiC mixed powder, monomer content is 30wt% of SiC mixed powder, photoinitiator content is 2.2wt% of monomer mass; compatibilizer is stearin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com