Gradual intensity electron beam radiation coating solidification process

A technology of electron beam radiation and curing process, which is applied in the field of radiation curing, can solve the problems of poor adhesion and different energy at the interface contact, and achieve strong adhesion, large coating thickness and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

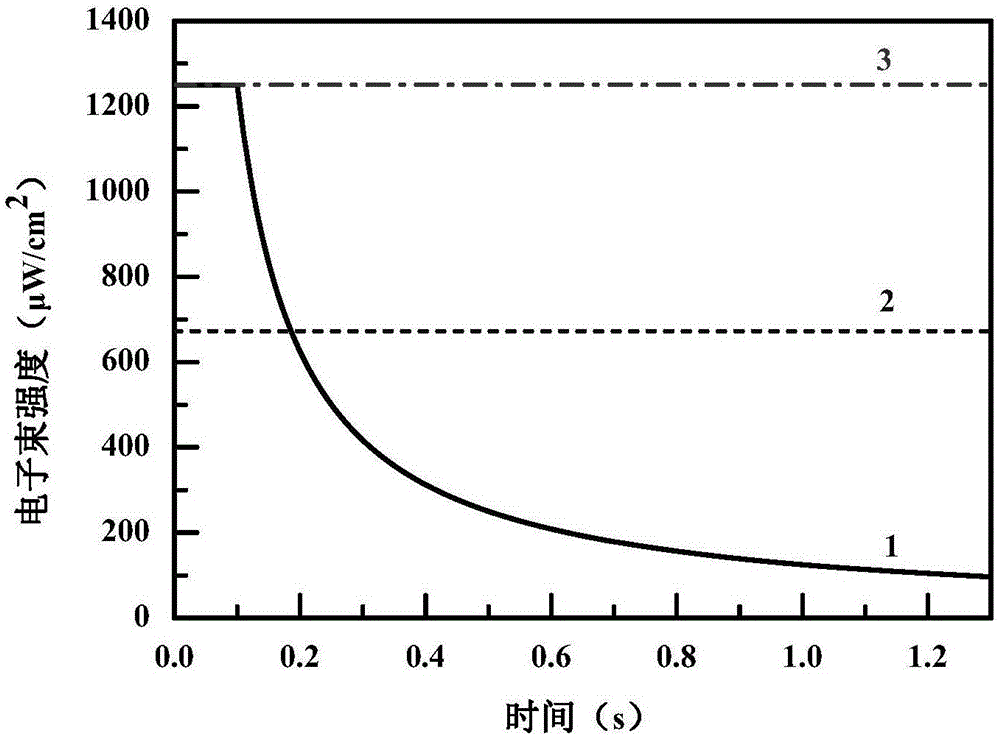

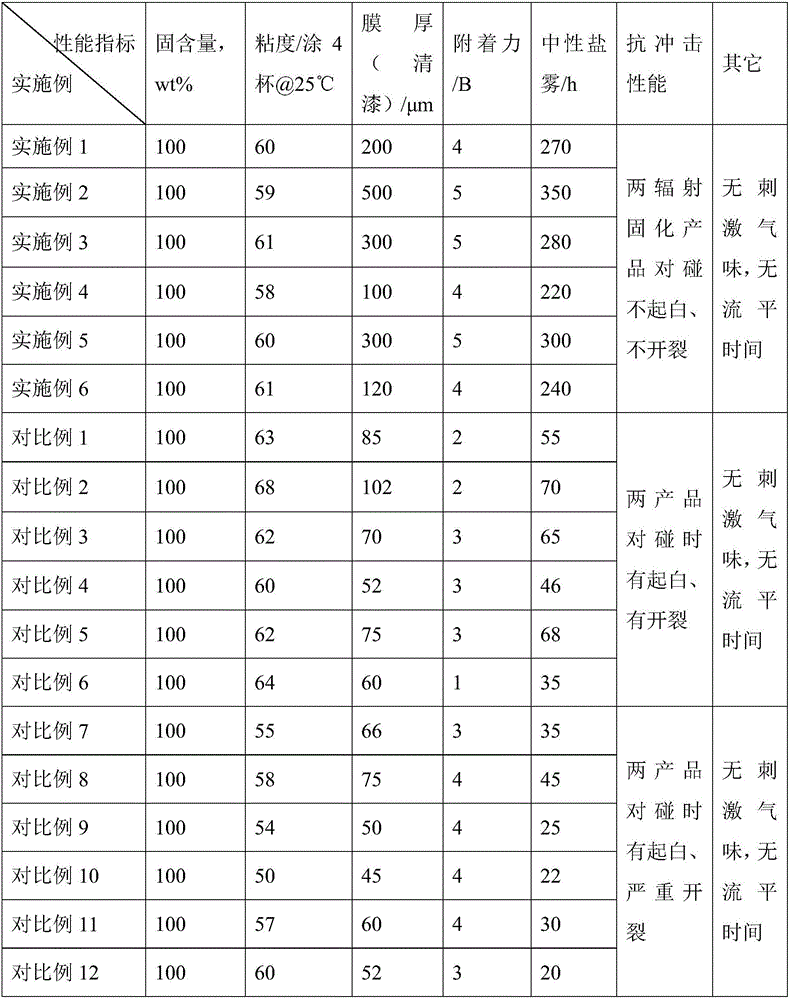

[0028] Coating the paint on the metal parts, the metal parts are 80mm×80mm stainless steel plates, the coating thickness is 200μm, and cured by electron beam radiation in a vacuum environment, the curing parameters are: radiation voltage 400KeV; electron beam dose 40KGy; beam current 100mA; electronic accelerator drive speed 100m / min; vacuum degree 10 -3 bar, time 1.3s. During the electron beam irradiation process, the electron beam intensity E applied in the first 0.1s is 1250μW / cm 2 , and then start from 0.1s, apply the electron beam intensity according to E=125 / t, and stop the application at 1.3s to complete the curing of the coating.

Embodiment 2

[0030] The paint is coated on the metal parts, the metal parts are 80mm×80mm stainless steel plates, the coating thickness is 500μm, and it is cured by electron beam radiation in a vacuum environment. The curing parameters are: radiation voltage 1MeV; electron beam dose 100KGy; beam current 150mA; electronic accelerator drive speed 850m / min; vacuum degree 10 -1 bar, time 2.5s. During the electron beam irradiation process, the electron beam intensity E applied in the first 0.1s is 2408μW / cm 2 , and then start from 0.1s, apply the electron beam intensity according to E=240.8 / t, and stop the application at 2.5s to complete the curing of the coating.

Embodiment 3

[0032] The paint is coated on the metal parts, the metal parts are 80mm×80mm stainless steel plates, the thickness of the coating is 300μm, and it is cured by electron beam radiation in a nitrogen environment. The curing parameters are: radiation voltage 800KeV; electron beam dose 60KGy; Current 120mA; electronic accelerator drive speed 300m / min; nitrogen concentration 300mg / L, time 0.6s. During the electron beam irradiation process, the electron beam intensity E applied in the first 0.1s is 586μW / cm 2 , and then start from 0.1s, apply the electron beam intensity according to E=58.6 / t, stop the application at 0.6s, and complete the curing of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com