Patents

Literature

33results about How to "Large coating thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

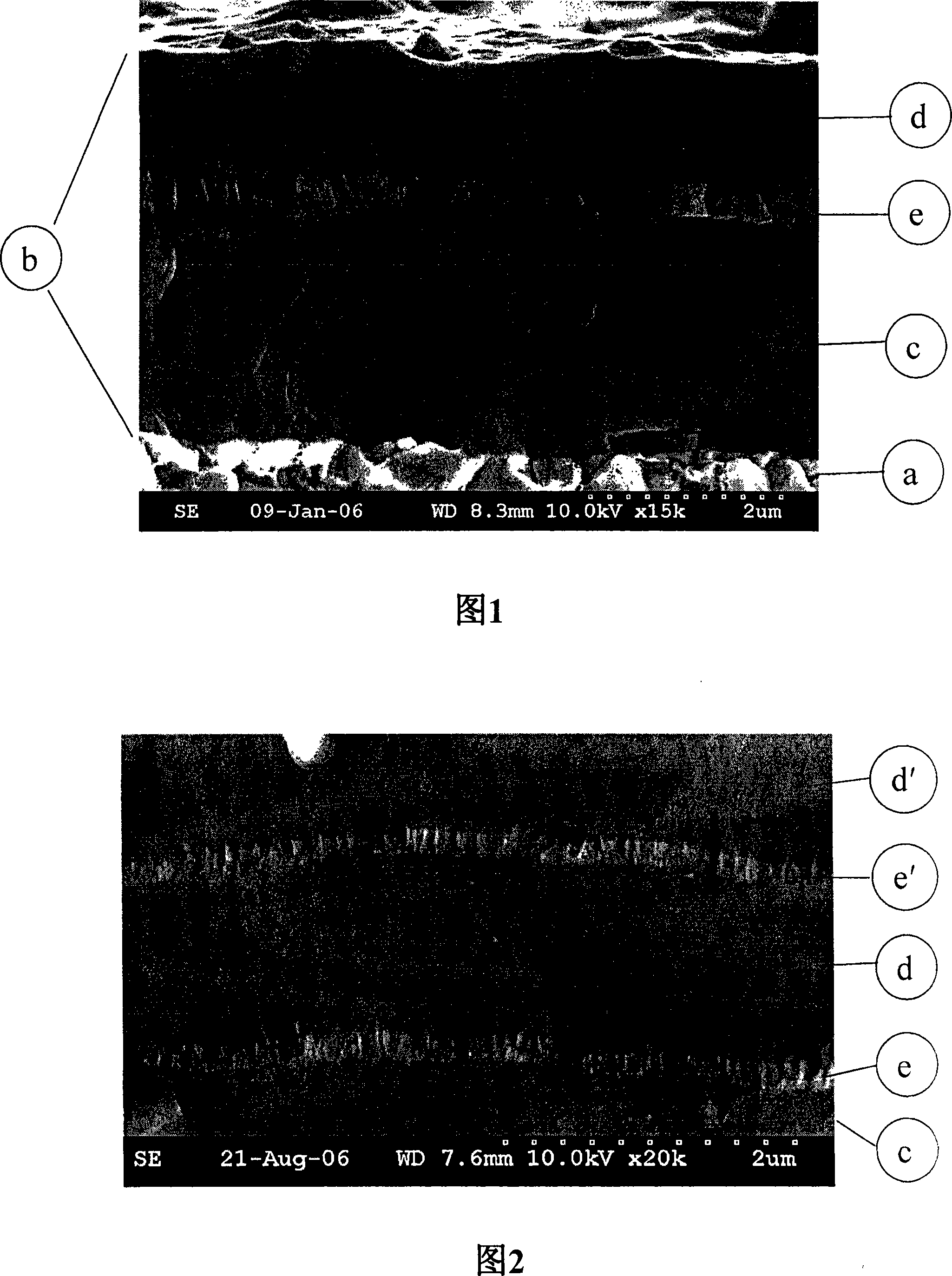

Coated cemented carbide endmill

InactiveCN101204864AIncreasing the thicknessThickness does not decreaseLayered productsVacuum evaporation coatingWear resistantMetal machining

Owner:SANDVIK INTELLECTUAL PROPERTY AB

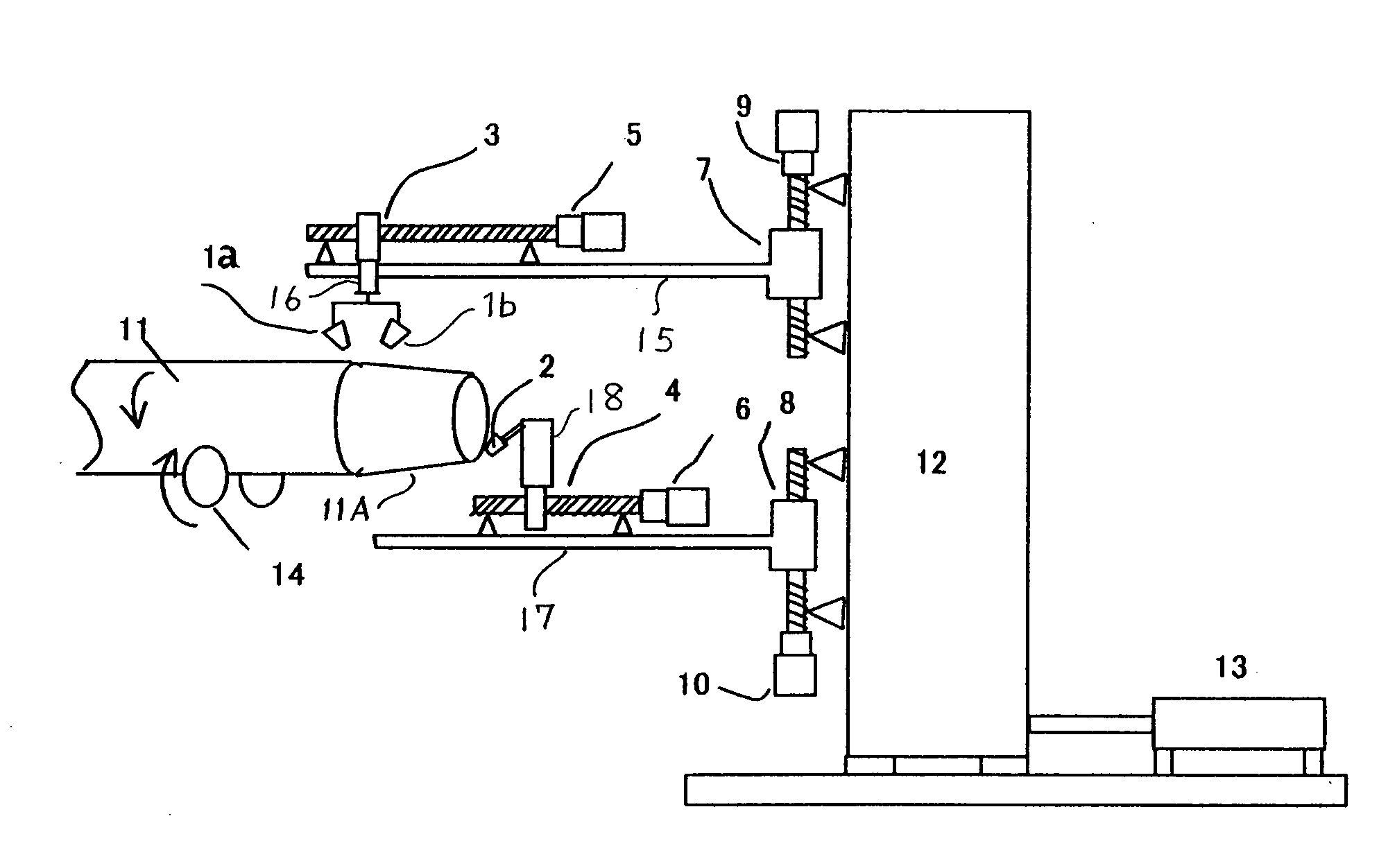

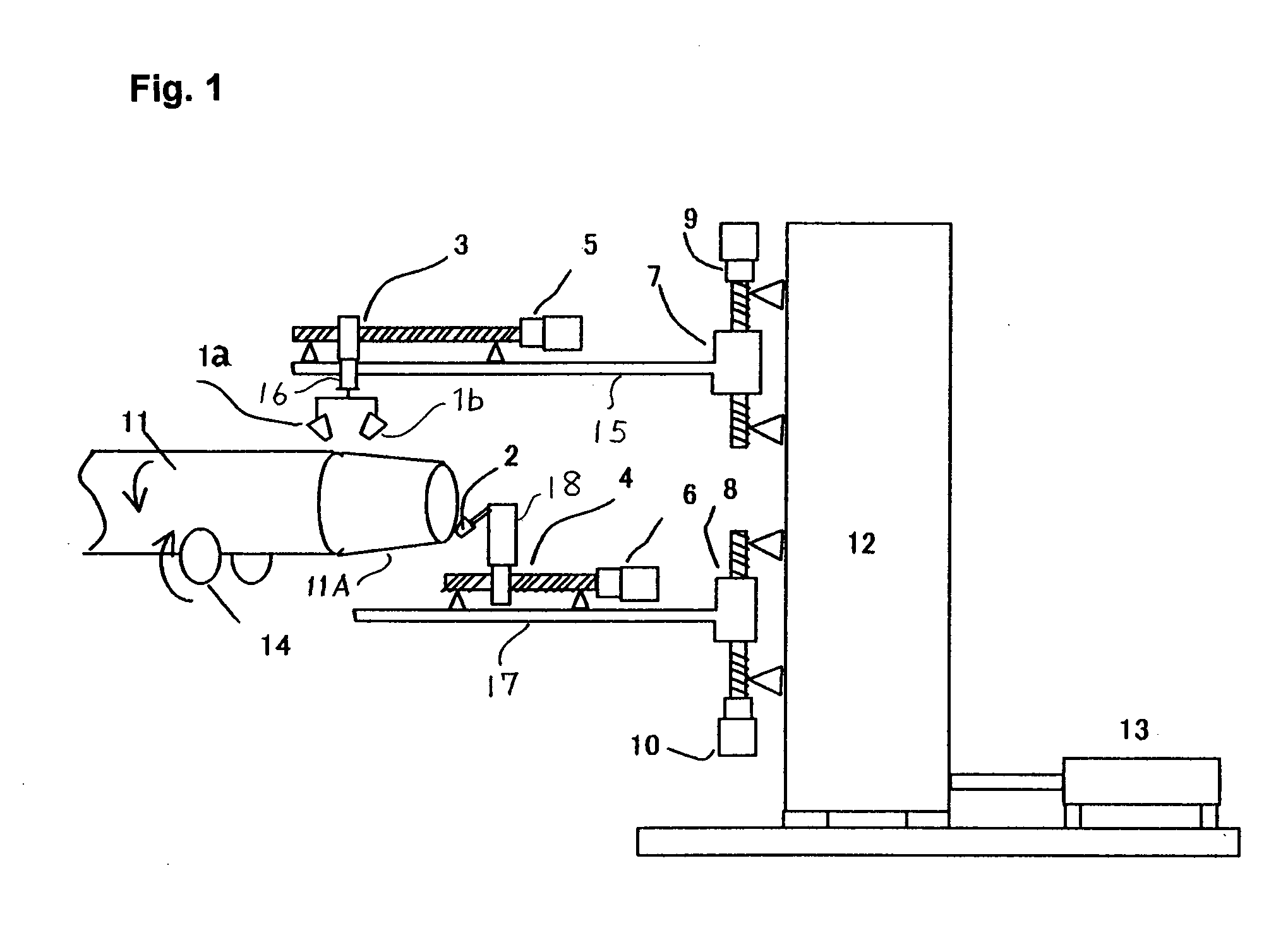

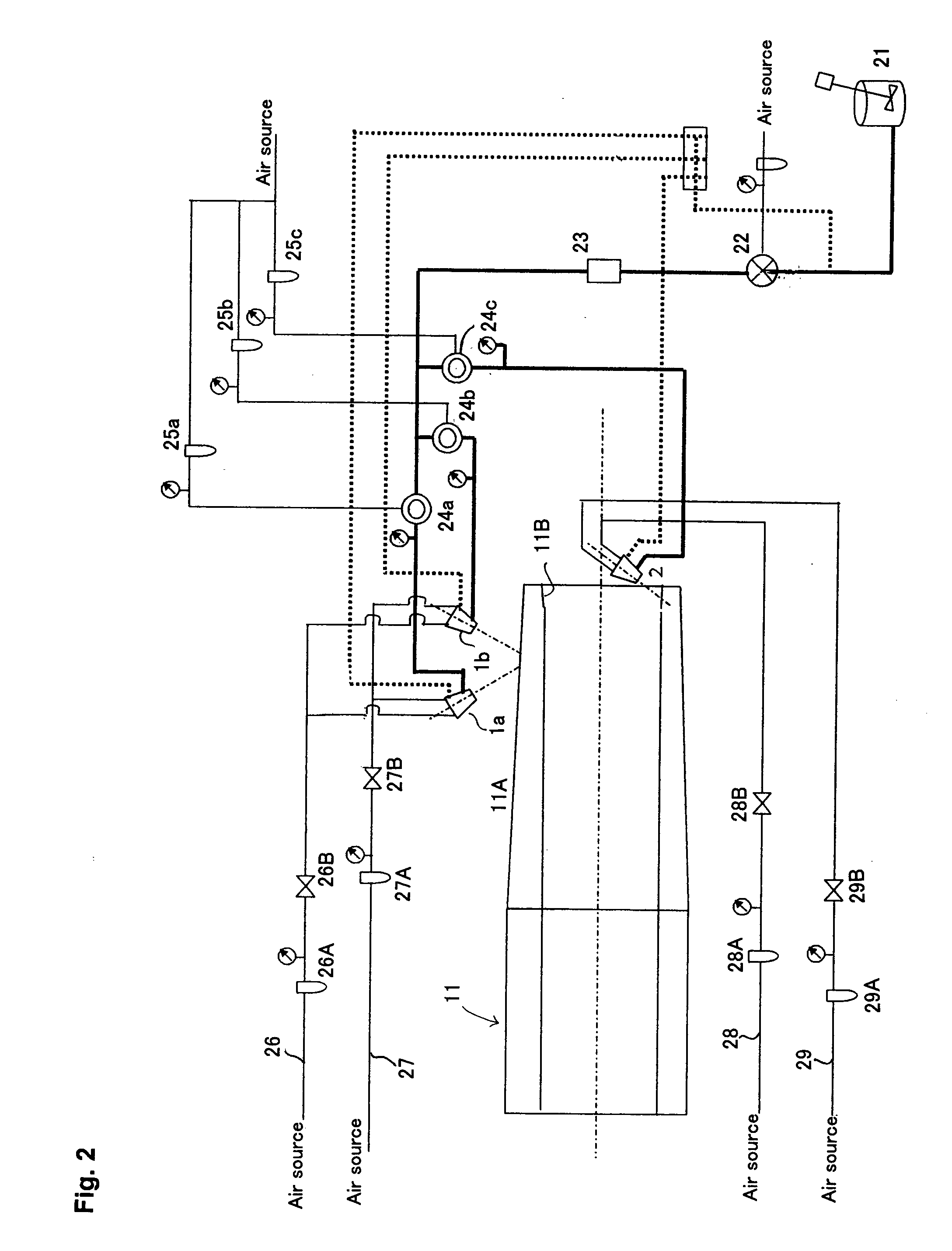

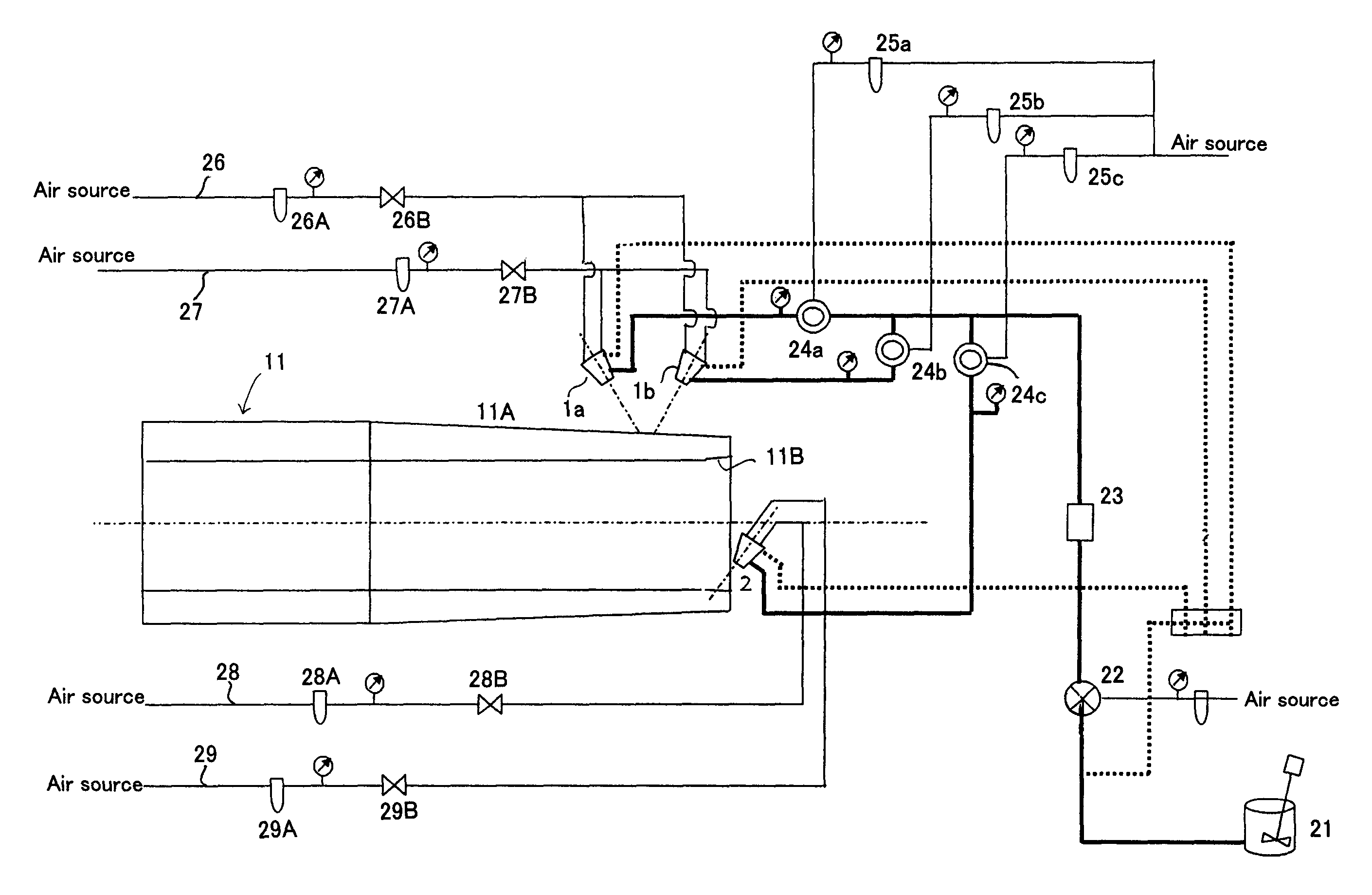

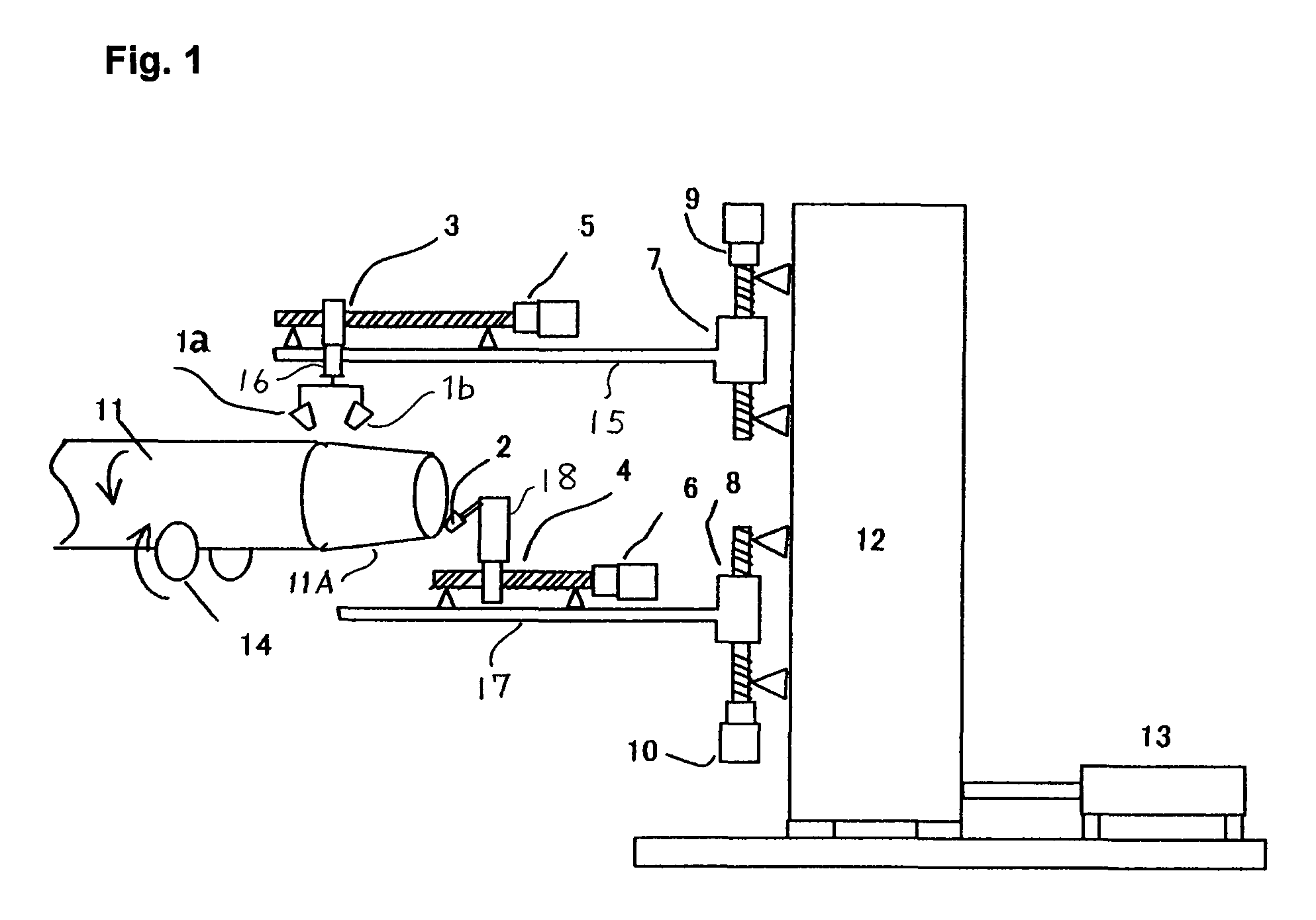

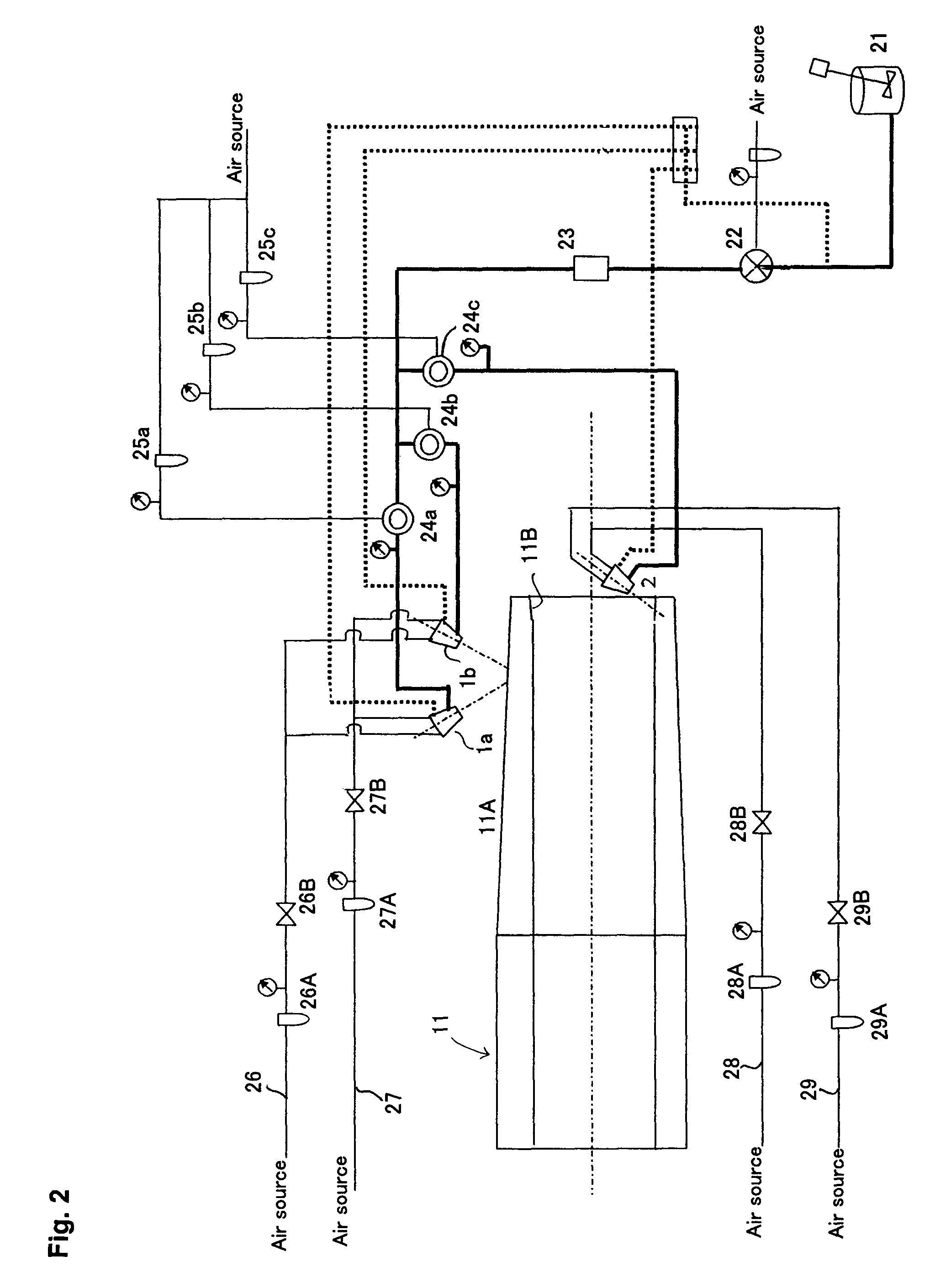

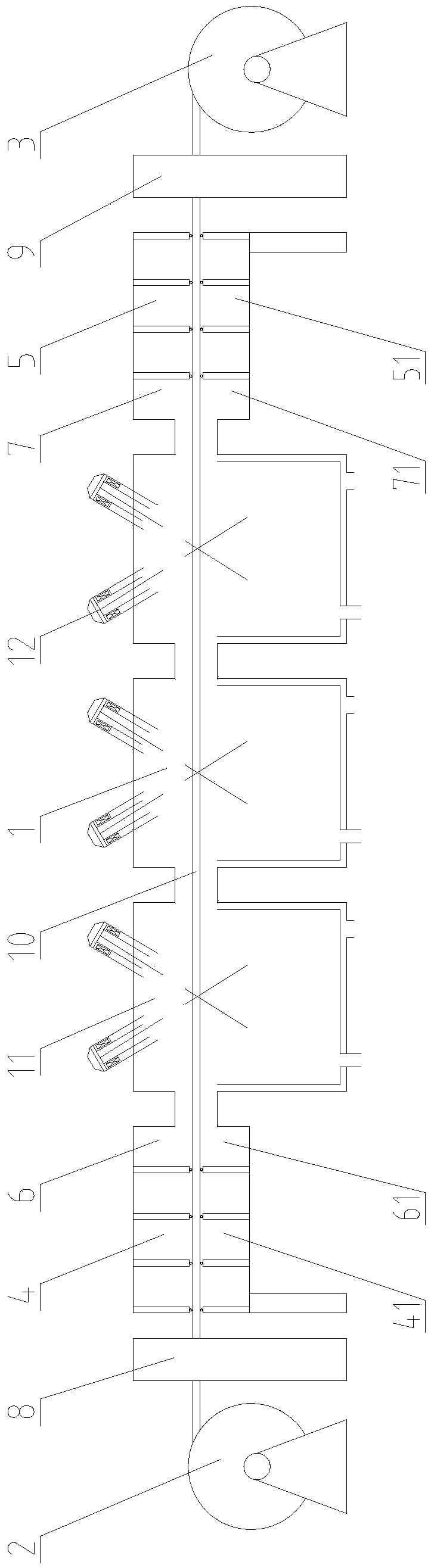

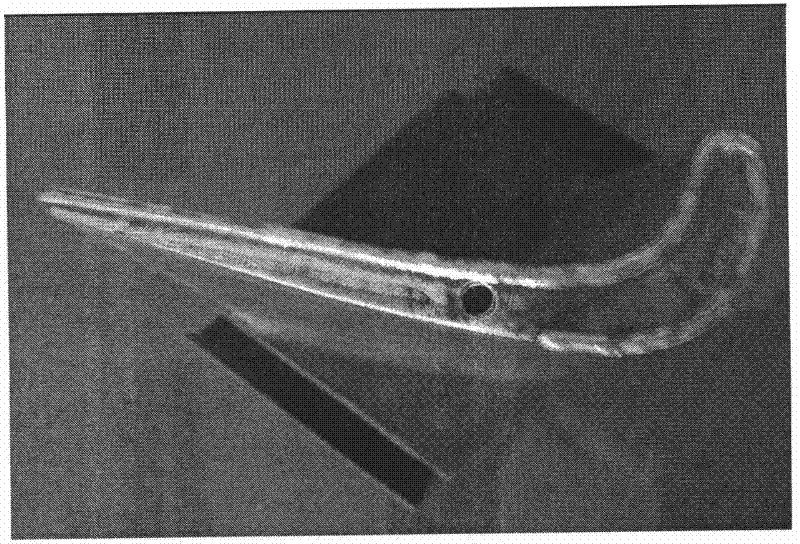

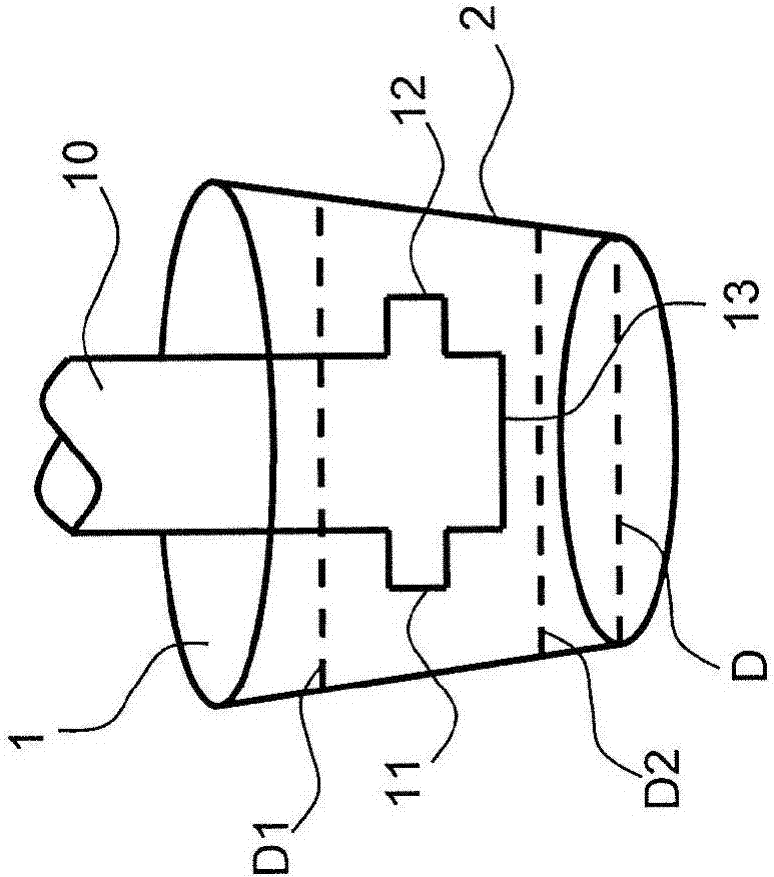

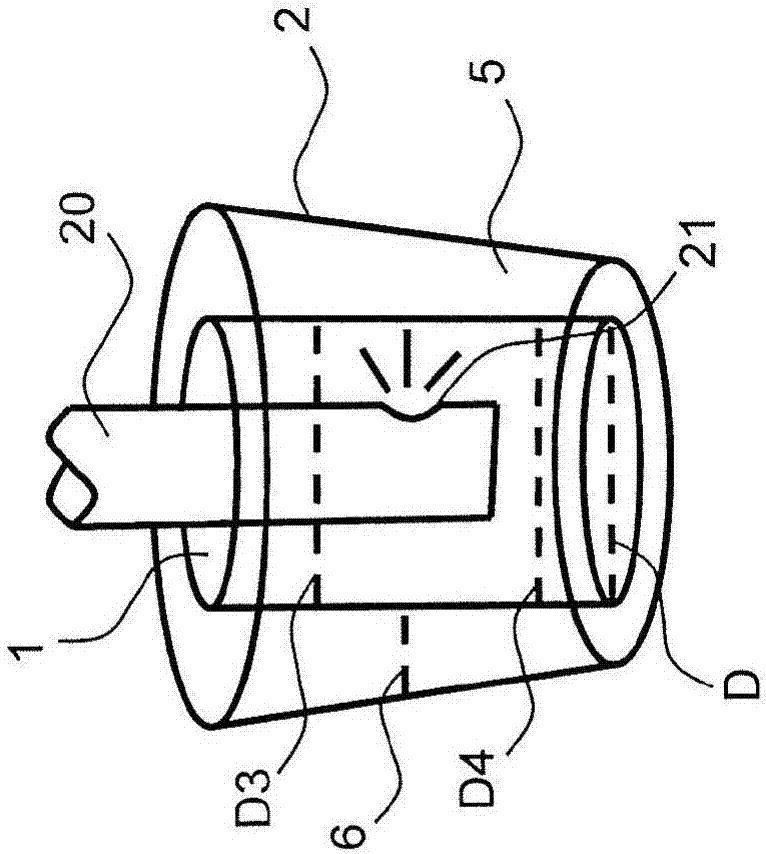

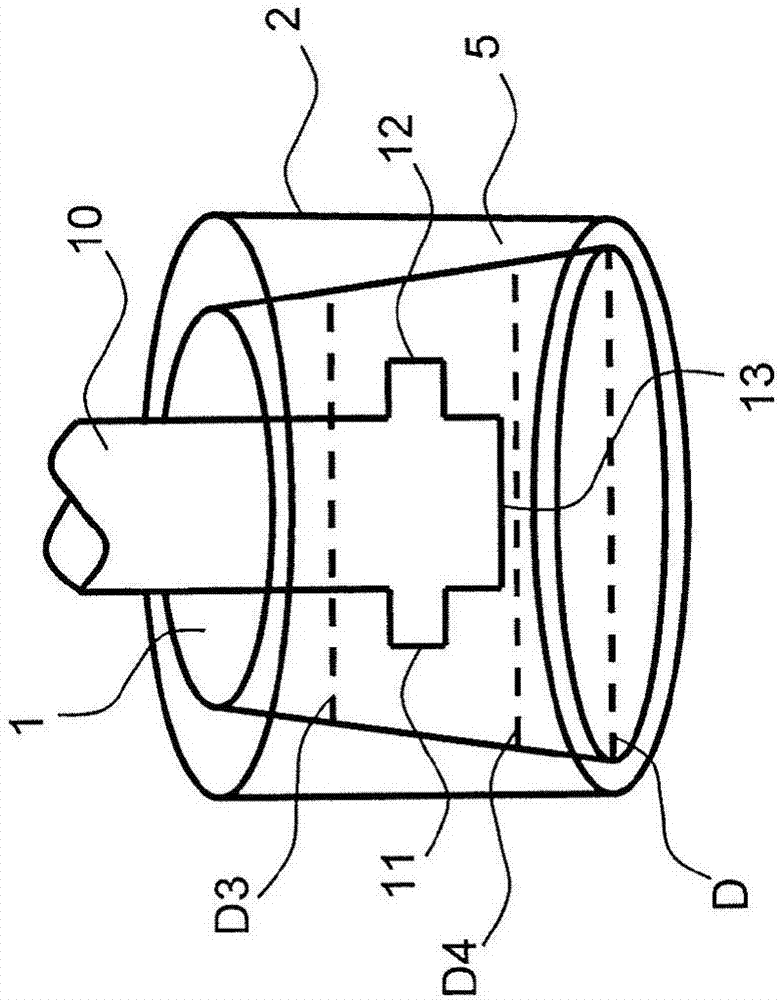

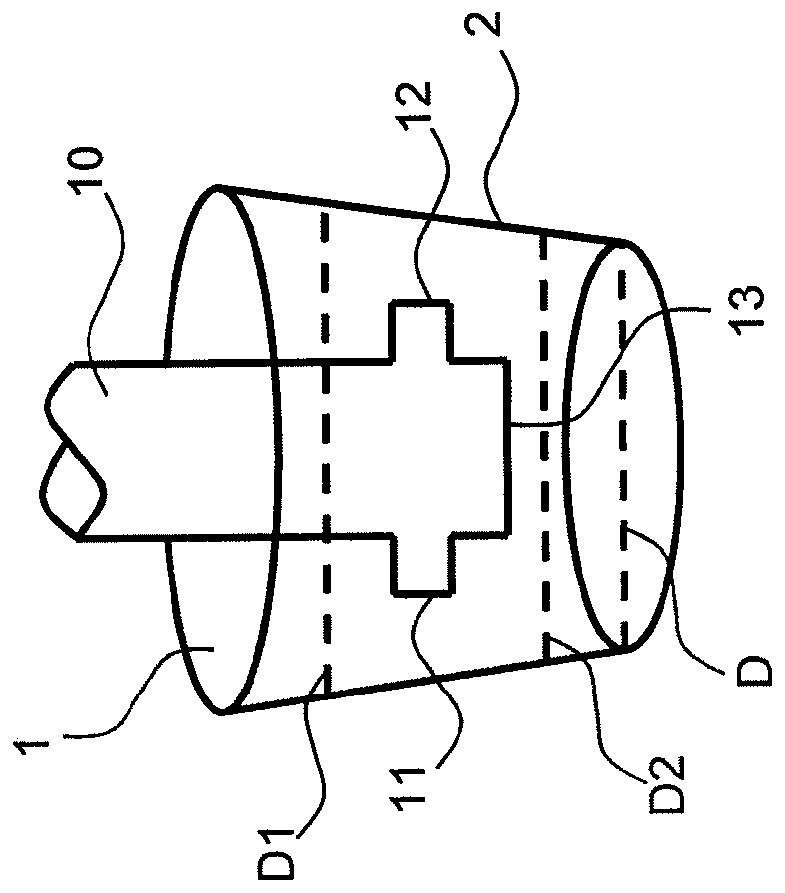

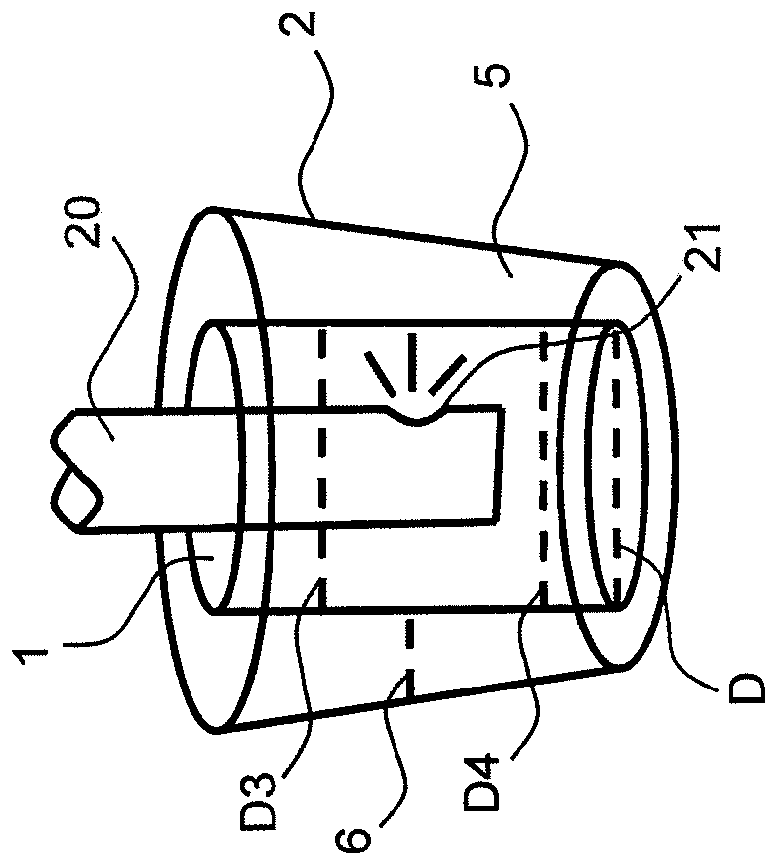

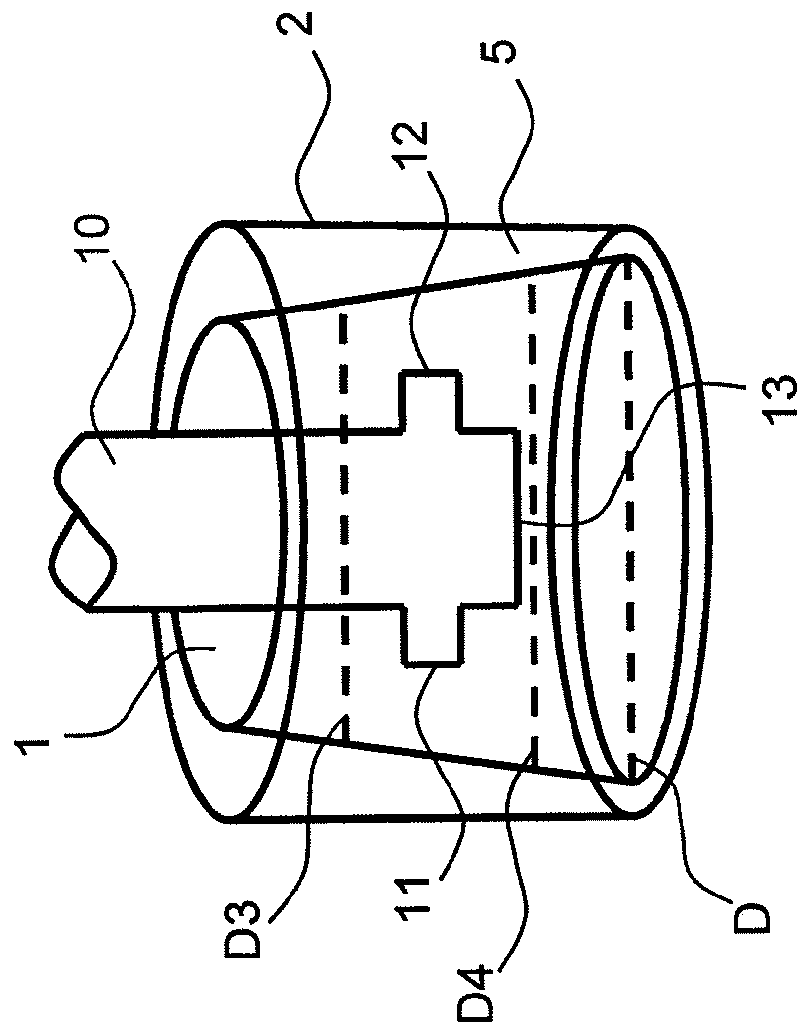

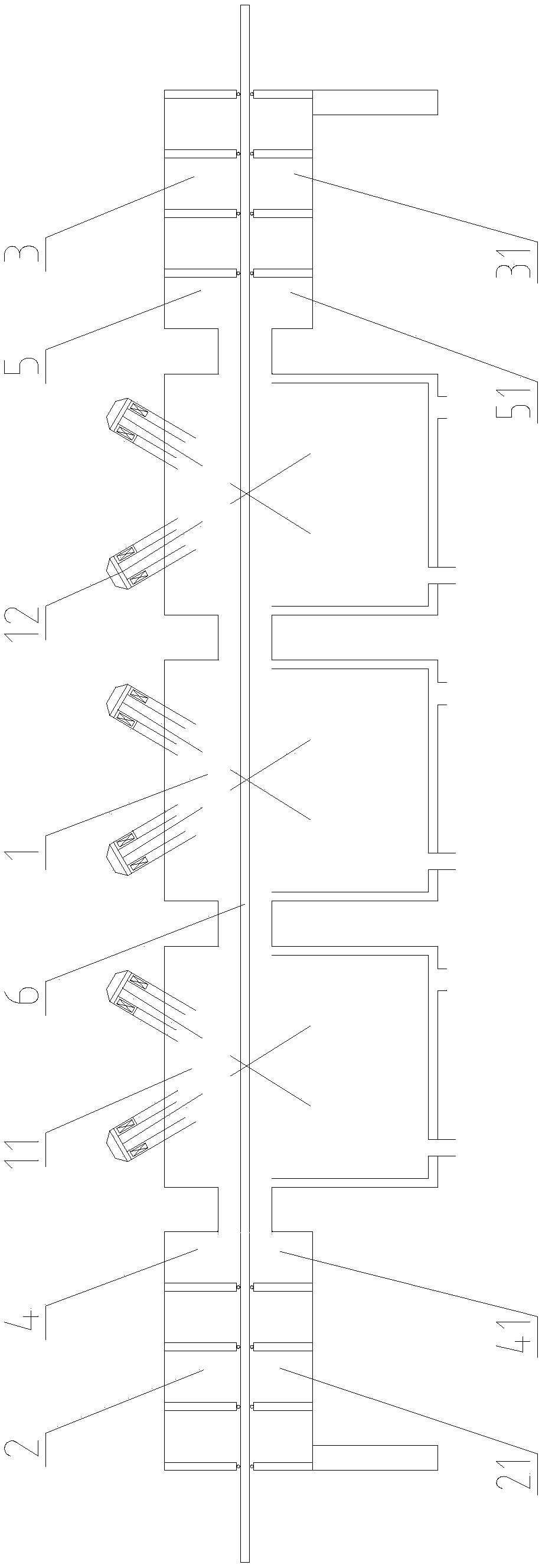

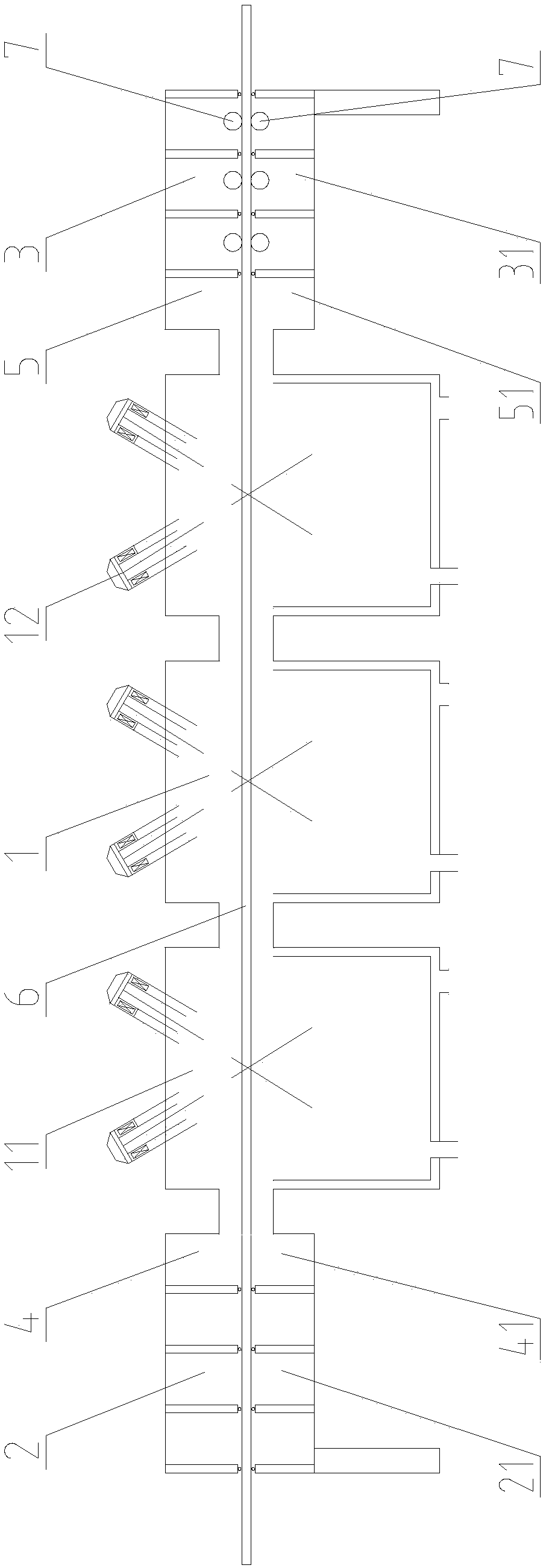

Coating apparatus for applying a UV curable resin to a threaded end of a steel pipe

ActiveUS20130228122A1Prevent rustImprove adhesionPretreated surfacesCorrosion preventionResin coatingEngineering

A coating apparatus for forming a thin UV curable resin coating on threaded end portions of a steel pipe comprises a spraying unit having at least two nozzles adapted to spray the resin coating composition by pneumatic atomization toward the threaded end portion of the steel pipe, a resin supply system for supplying the resin coating composition to each nozzle, and a first nozzle support means which supports each nozzle for movement in the axial direction of the steel pipe and in the vertical direction. The two nozzles are disposed at different positions at least in the axial direction of the steel pipe at angles which are sloped such that the sprayed streams from the nozzles approach each other. The resin supply system has a regulator for maintaining the spraying air pressure of the resin coating composition in each nozzle of the spraying unit at a predetermined respective value.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

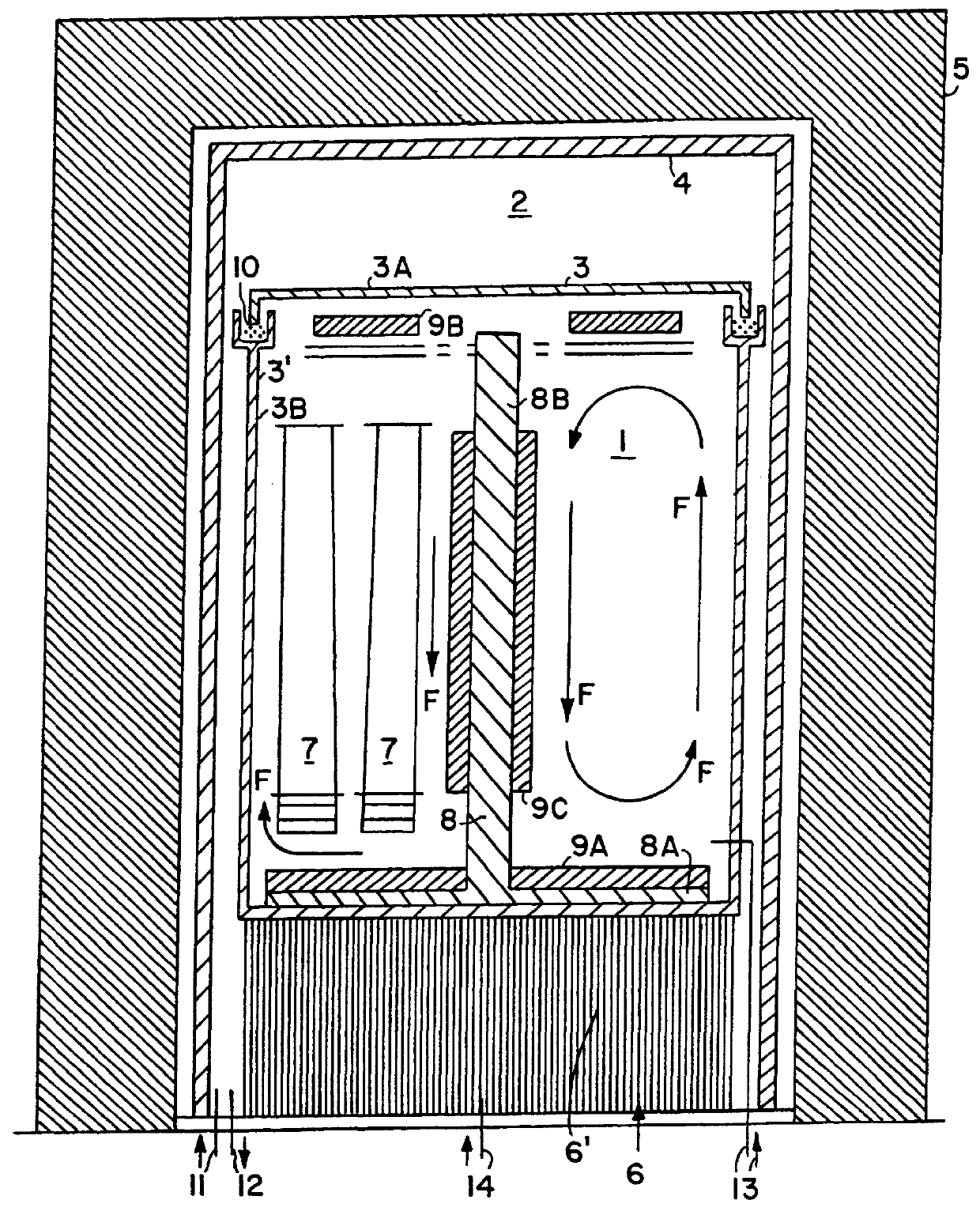

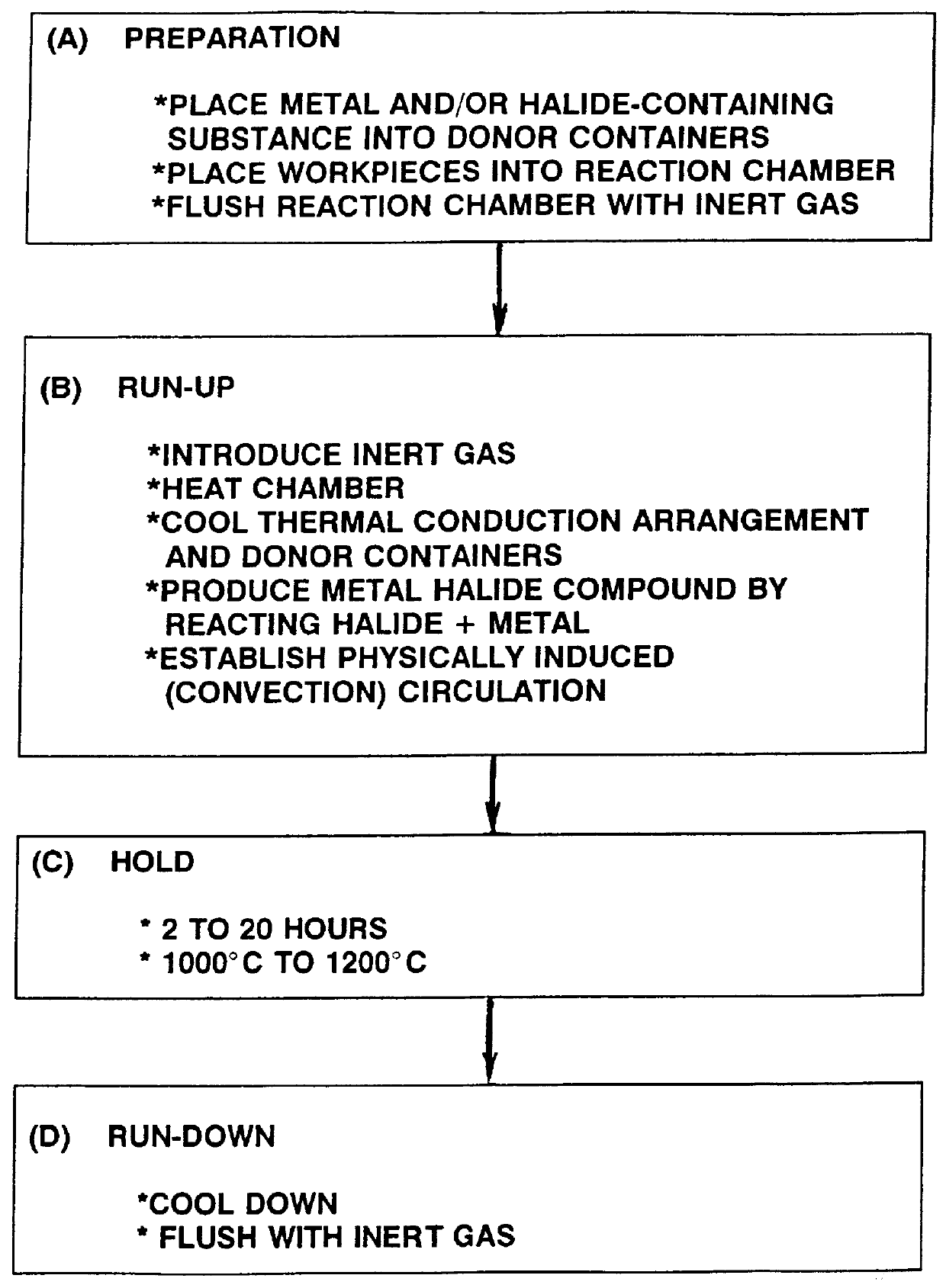

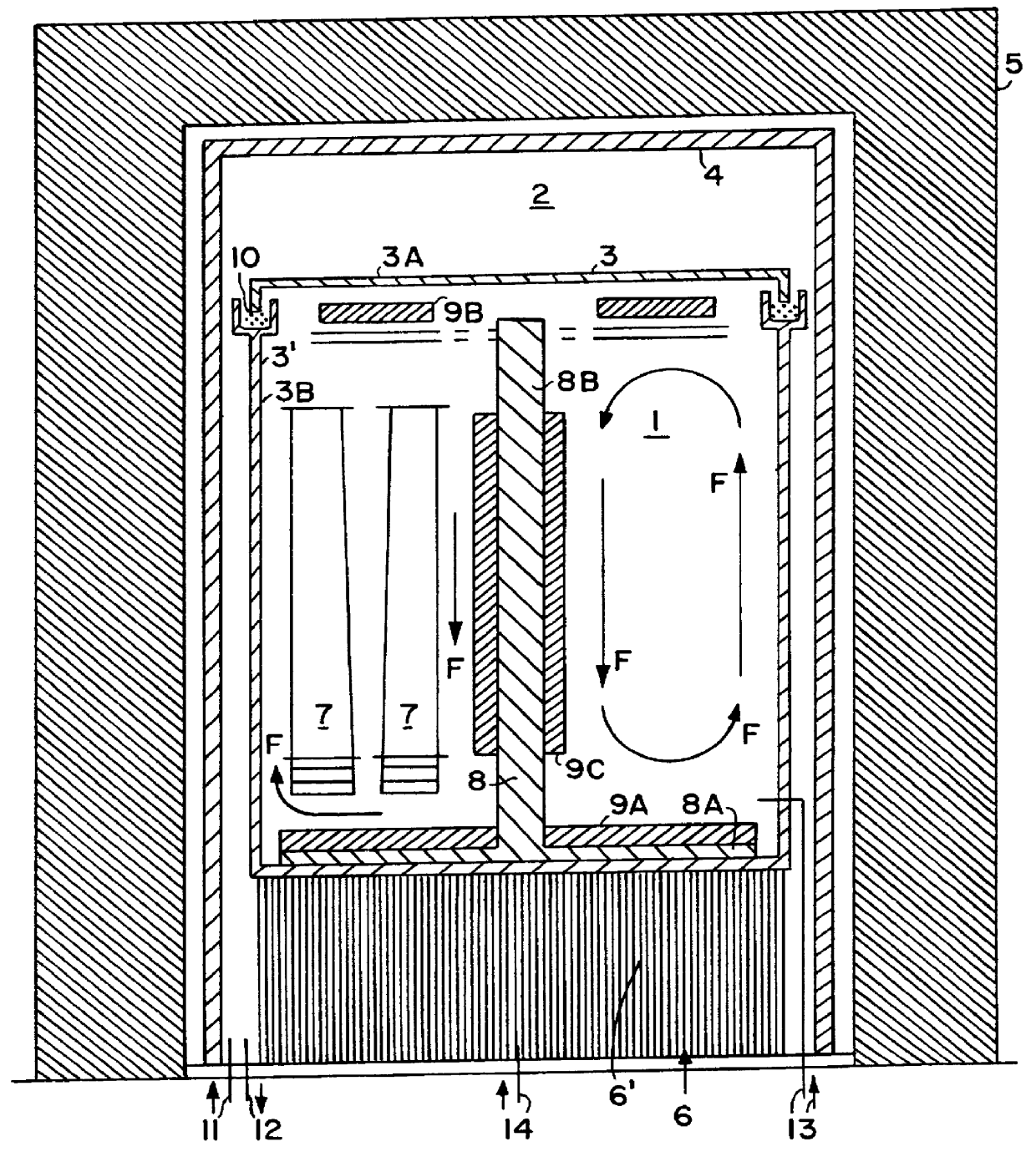

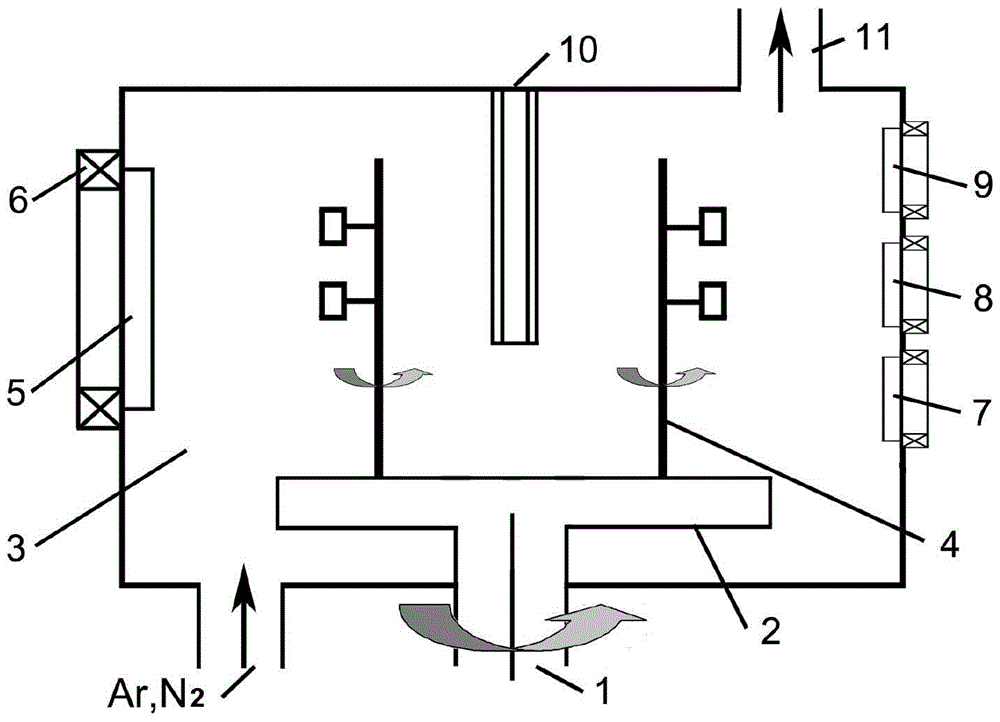

Method and apparatus for gas phase diffusion coating of workpieces made of heat resistant material

InactiveUS6120843AAvoid the needImprove surface qualityEfficient propulsion technologiesSolid state diffusion coatingSmooth surfaceCompound (substance)

In a method for coating workpieces with a coating material by a gas phase diffusion coating process, the coating material is conveyed in the form of a metal halide compound from a coating material source (9A, 9B, 9C) to the workpiece (7) by means of a metal halide gas circulation flow (F). The gas circulation flow (F) is physically induced due to convection by establishing a temperature gradient between the workpiece (7) and the coating material source (9A, 9B, 9C), and is reinforced by the chemical reactions taking place. An apparatus for carrying out a gas phase diffusion process includes a reaction vessel (3) enclosing a reaction chamber (1) in which the workpiece (7) is arranged. The apparatus further includes a metal halide generator (9A, 9B, 9C) arranged in the reaction chamber (1), and a heater (5) as well as a cooling device (6) and a thermal conduction arrangement (8) for establishing a temperature gradient between the workpiece (7) and the metal halide generator (9A, 9B, 9C). The method and apparatus produce a diffusion coating having a uniform thickness and a high quality smooth surface, even on large workpiece surfaces.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

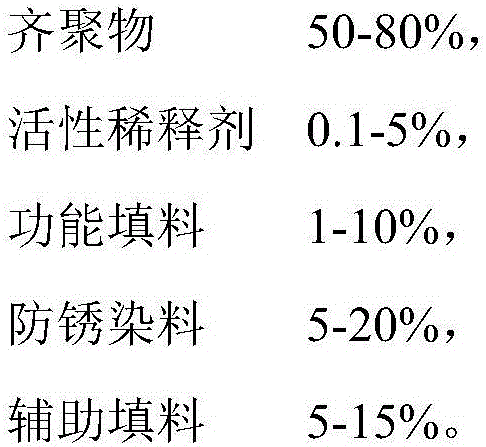

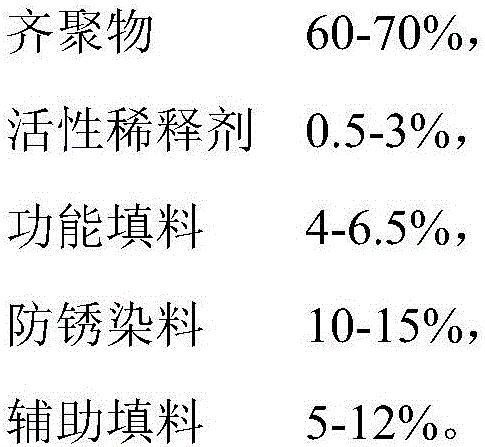

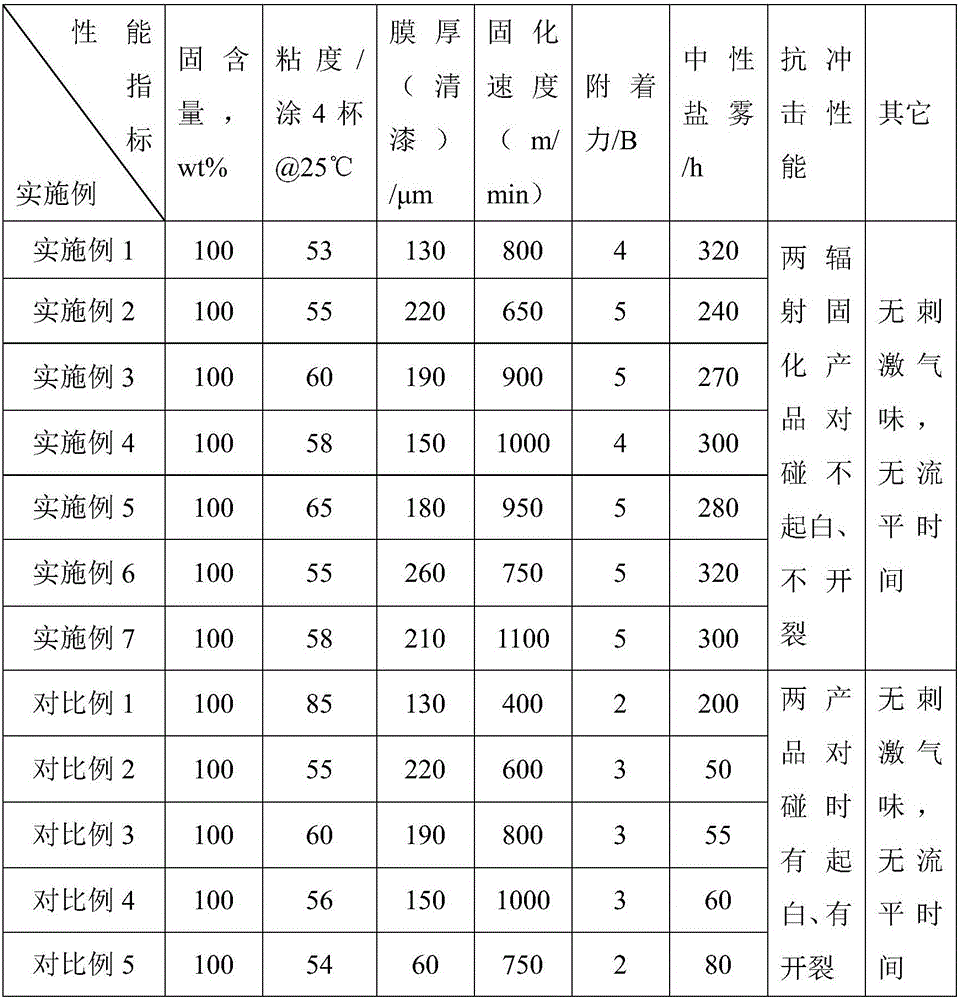

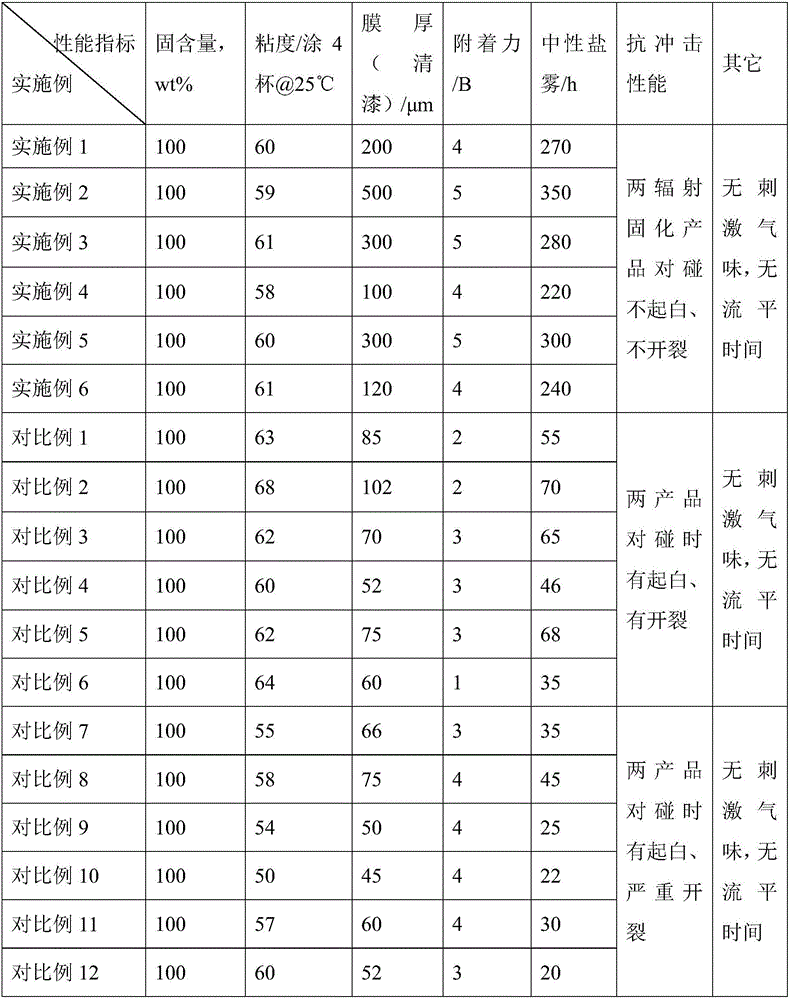

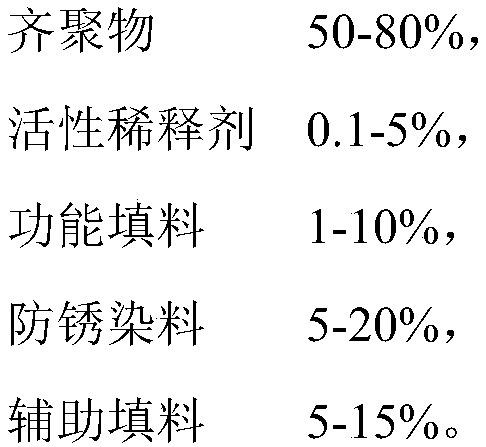

Electron beam radiation curing coating for metal heavy anti-corrosion

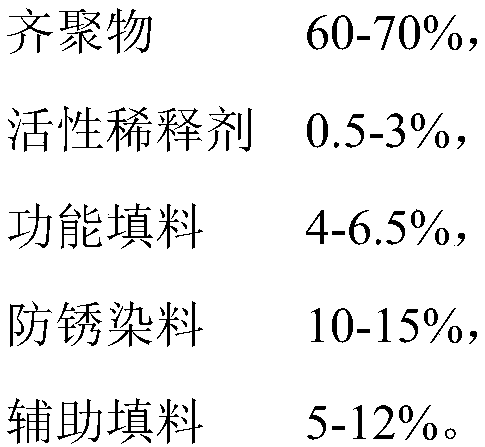

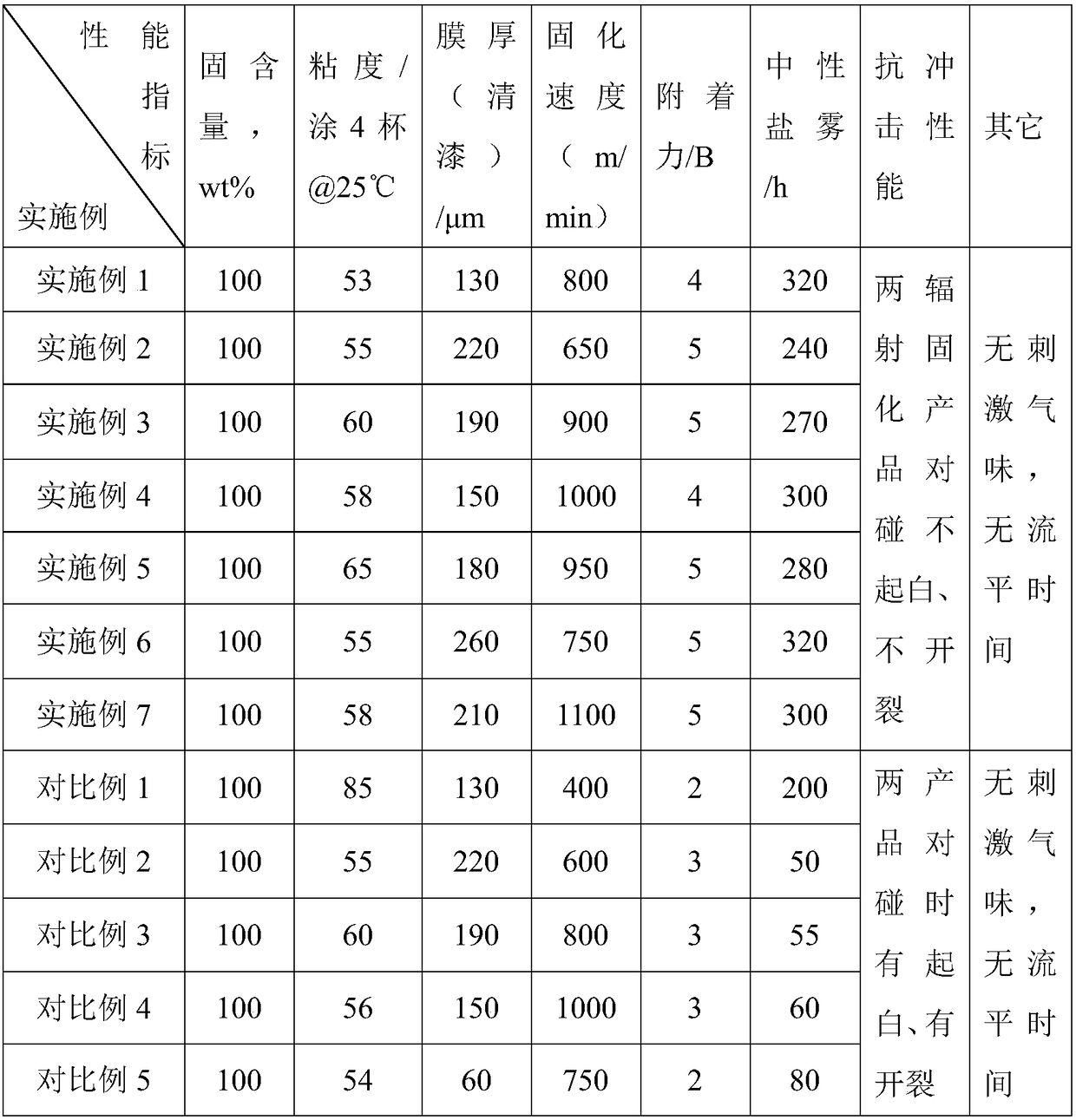

ActiveCN106433258AImprove curing efficiencyReduce energy consumptionAnti-corrosive paintsBeam energyOligomer

The invention discloses an electron beam radiation curing coating for metal heavy anti-corrosion. The coating is prepared from, by mass, 50%-80% of oligomer, 0.1-0.5% of reactive diluent, 1-10% of functional filler, 5-20% of antirust dyestuff and 5-15% of auxiliary filler, and the total mass percentage of the components is 100%. The curing coating for metal heavy anti-corrosion is cured by electron beam radiation, has the advantages of high efficiency and energy conservation, environment friendship and convenient operation, cured depth of the coating is high, thickness is big, and the adhesive force between the coating and the substrate is strong. A conductive carbon material is doped in the curable coating, thus the problem of metal heavy anti-corrosion is solved while electron beam energy absorption is avoided, and it is guaranteed that cured efficiency is not affected. The electron beam radiation curing coating for metal heavy anti-corrosion has excellent wear-resistance and corrosion-resistance, can be applied to the field of metal heavy anti-corrosion anti-corrosion, and is particularly applicable to the field of maritime work heavy anti-corrosion.

Owner:NANJING INST OF TECH +1

Method and apparatus for gas phase diffusion coating of workpieces made of heat resistant material

InactiveUS6156123AAvoid the needImprove surface qualityEfficient propulsion technologiesSolid state diffusion coatingChemical reactionGas phase

In a method for coating workpieces with a coating material by a gas phase diffusion coating process, the coating material is conveyed in the form of a metal halide compound from a coating material source (9A, 9B, 9C) to the workpiece (7) by means of a metal halide gas circulation flow (F). The gas circulation flow (F) is physically induced due to convection by establishing a temperature gradient between the workpiece (7) and the coating material source (9A, 9B, 9C), and is reinforced by the chemical reactions taking place. An apparatus for carrying out a gas phase diffusion process includes a reaction vessel (3) enclosing a reaction chamber (1) in which the workpiece (7) is arranged. The apparatus further includes a metal halide generator (9A, 9B, 9C) arranged in the reaction chamber (1), and a heater (5) as well as a cooling device (6) and a thermal conduction arrangement (8) for establishing a temperature gradient between the workpiece (7) and the metal halide generator (9A, 9B, 9C). The method and apparatus produce a diffusion coating having a uniform thickness and a high quality smooth surface, even on large workpiece surfaces.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

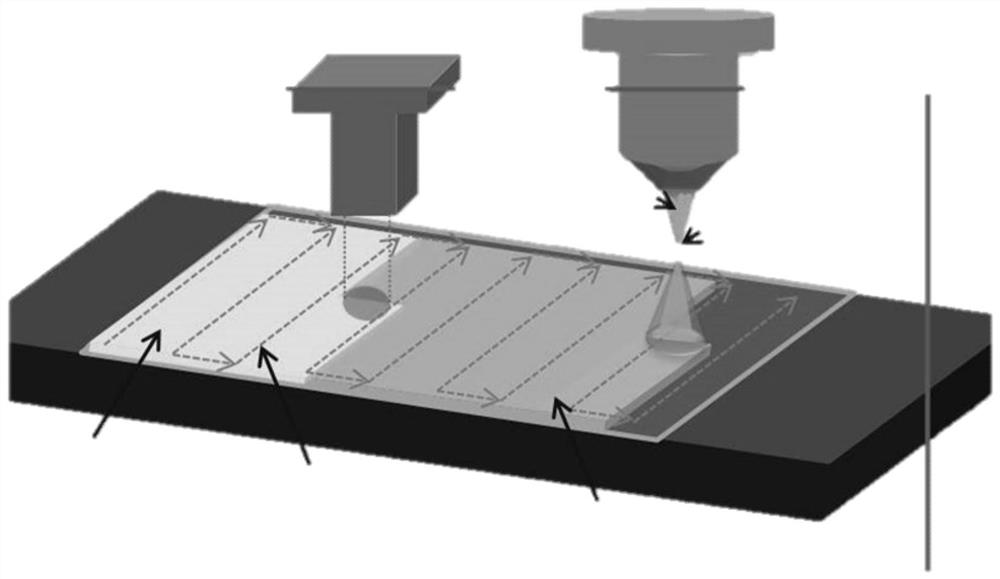

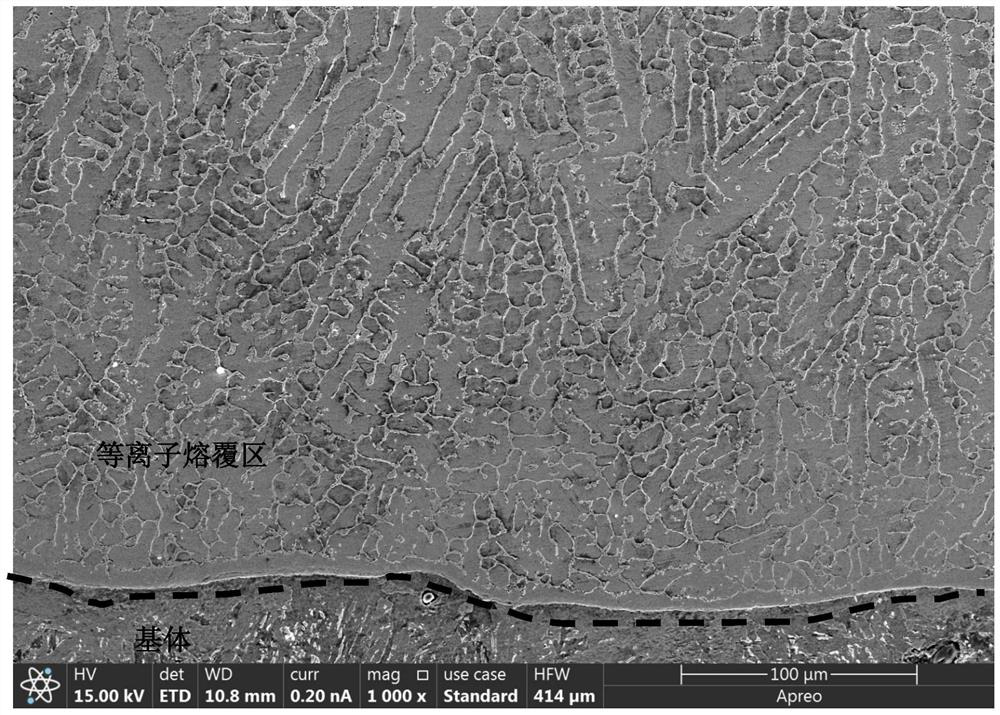

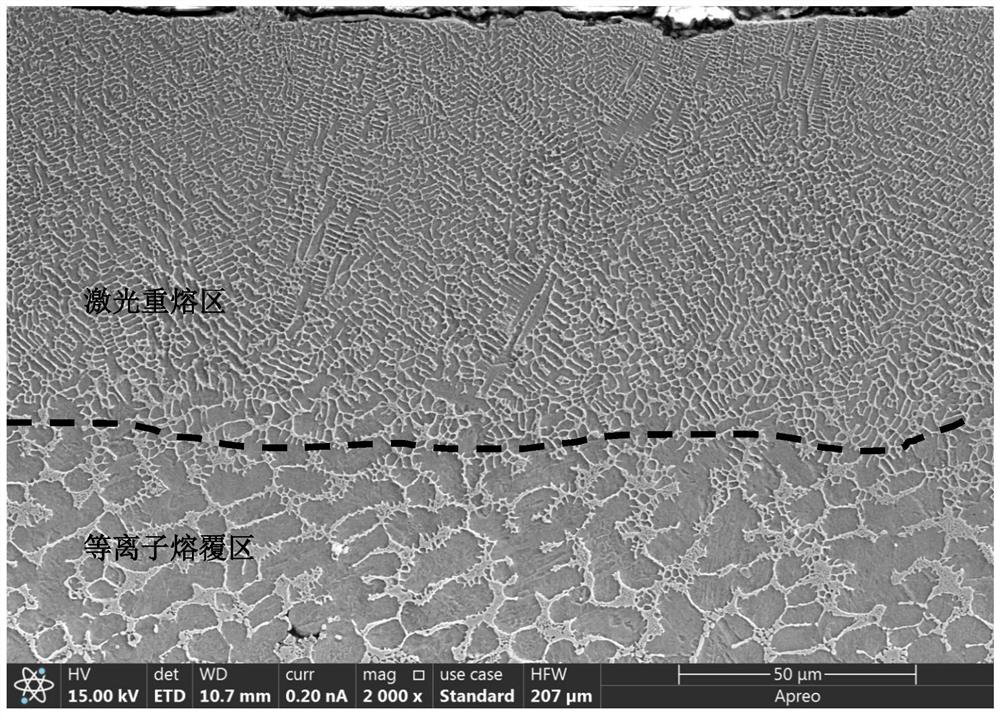

Corrosion-resistant and wear-resistant coating with gradient composite structure and preparation method thereof

ActiveCN113122841ASmall plasticityGood plasticityMetallic material coating processesHigh entropy alloysEquiaxed crystals

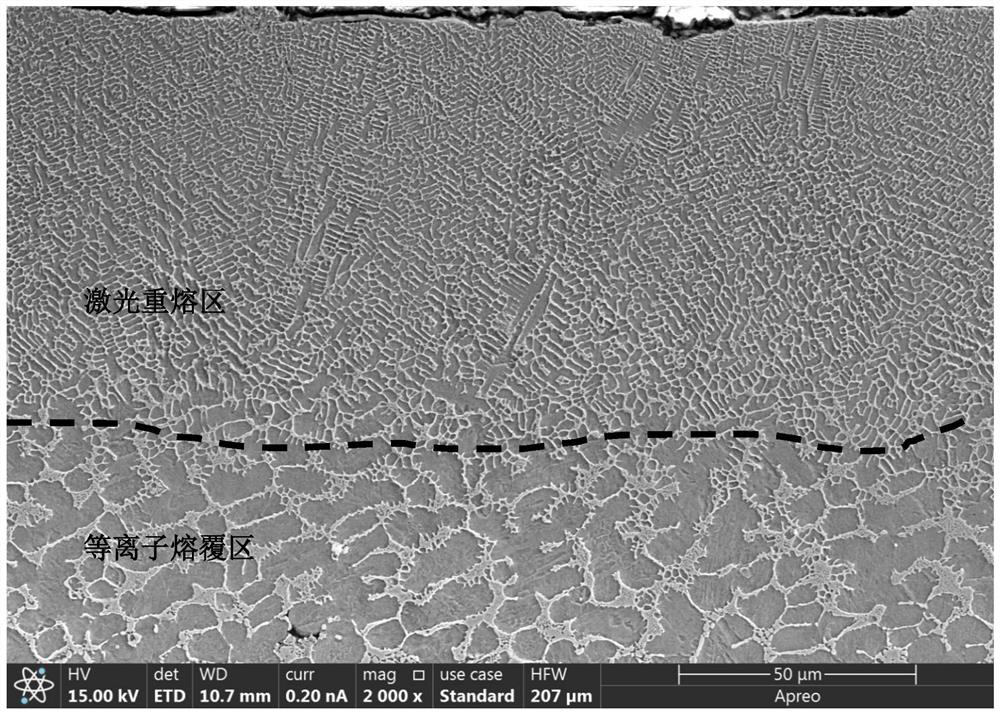

The invention discloses a corrosion-resistant and wear-resistant coating with a gradient composite structure and a preparation method thereof. According to the corrosion-resistant and wear-resistant coating, by cladding alloy powder on the surface of a pretreated matrix through a plasma cladding method to obtain an alloy layer with a large-thickness dendritic structure, and then re-melting and fusing growth of thick dendrites on the surface of the alloy layer through non-powder-feeding laser, so that a fine equiaxed crystal structure is obtained. According to the preparation method, a thick dendrite structure is formed after plasma cladding, dendrites have a nail pile effect on a matrix and have a supporting effect on a subsequent laser high-speed cladding layer, it is guaranteed that a large-thickness coating is obtained, combination with the matrix is strengthened, and the molten high-entropy alloy powder is fully and evenly mixed; and through subsequent laser remelting, thick dendrites can be fused, fine and compact isometric crystals are obtained, propagation of a corrosive medium is blocked, and corrosion resistance is improved.

Owner:OCEAN UNIV OF CHINA

Non-stick coating and preparation method thereof, pot, and cooking equipment

ActiveCN108977747AHigh hardnessHigh bonding strengthCooking-vessel materialsMolten spray coatingPowder mixtureCorrosion resistant

The invention relates to the technical field of electric heating appliances, and discloses a non-stick coating and a preparation method thereof, a pot, and cooking equipment. The method comprises: (1)pre-treating a matrix; (2) pre-heating the surface of the matrix obtained in the step (1); and (3) mixing silicon carbide powder and fluororesin powder to obtain a powder mixture, and carrying out plasma spraying treatment with the powder mixture to form a non-stick coating on the surface of the matrix. The non-stick coating of the invention is gray-black, and has advantages of scale resistance,high surface hardness, high coating adhesion, good scratch resistance, good corrosion resistance, good wettability, good heat transfer performance, long service life and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Non-stick coating and preparation method thereof as well as pot and cooking equipment

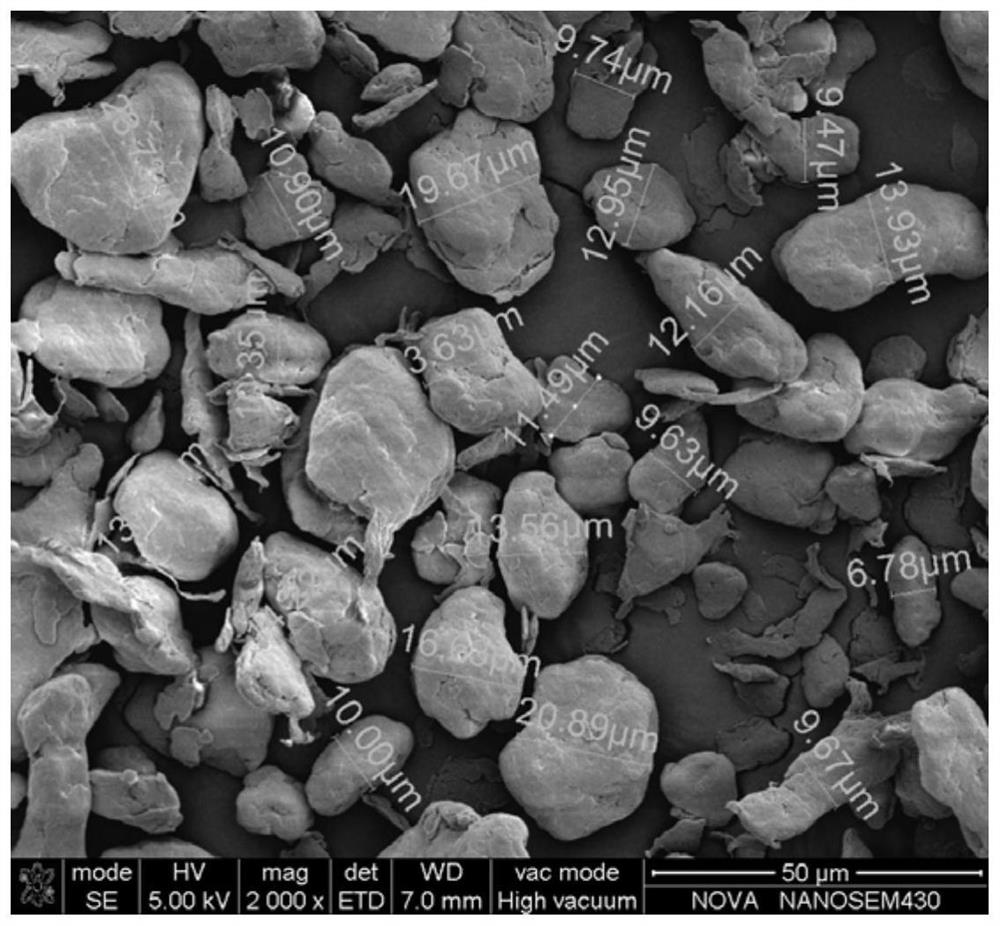

PendingCN108720620AImprove scratch resistanceIncrease deposition rateCooking-vessel materialsSpecial surfacesHigh surfaceMetal powder

The invention relates to the technical field of electro thermal equipment, and discloses a non-stick coating and a preparation method thereof as well as a pot and a cooking device. The method comprises the following steps of: (1) pretreating a substrate; (2) carrying out pre-heating treatment on the surface of the substrate obtained in the step (1); (3) performing cold spraying treatment on the substrate with the mixed powder of the metal powder and the polymer powder to form a non-stick coating on the surface of the substrate. The non-stick coating has the advantages of high surface hardness,high coating binding force, good scratch resistance, good corrosion resistance, long service life and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Non-stick coating and preparation method thereof, pot, and cooking equipment

ActiveCN108977748AHigh hardnessImprove hydrophobicityCooking-vessel materialsMolten spray coatingOxide ceramicThermal spraying

The invention relates to the technical field of electric heating appliances, and discloses a non-stick coating and a preparation method thereof, a pot, and cooking equipment. The method comprises: (1)pre-treating a matrix; (2) pre-heating the surface of the matrix obtained in the step (1); and (3) mixing metal oxide powder and fluororesin powder to obtain a powder mixture, and carrying out thermal spraying treatment with the powder mixture to form a non-stick coating on the surface of the matrix, wherein the metal oxide powder comprises alumina powder and tetravalent metal oxide ceramic powder. The non-stick coating of the invention has advantages of high surface hardness, high coating adhesion, good scratch resistance, good corrosion resistance, good wettability, long service life and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Coating apparatus for applying a UV curable resin to a threaded end of a steel pipe

ActiveUS9205441B2Prevent rustImprove adhesionPretreated surfacesCorrosion preventionSpray nozzleEngineering

A coating apparatus for forming a thin UV curable resin coating on threaded end portions of a steel pipe comprises a spraying unit having at least two nozzles adapted to spray the resin coating composition by pneumatic atomization toward the threaded end portion of the steel pipe, a resin supply system for supplying the resin coating composition to each nozzle, and a first nozzle support means which supports each nozzle for movement in the axial direction of the steel pipe and in the vertical direction. The two nozzles are disposed at different positions at least in the axial direction of the steel pipe at angles which are sloped such that the sprayed streams from the nozzles approach each other. The resin supply system has a regulator for maintaining the spraying air pressure of the resin coating composition in each nozzle of the spraying unit at a predetermined respective value.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

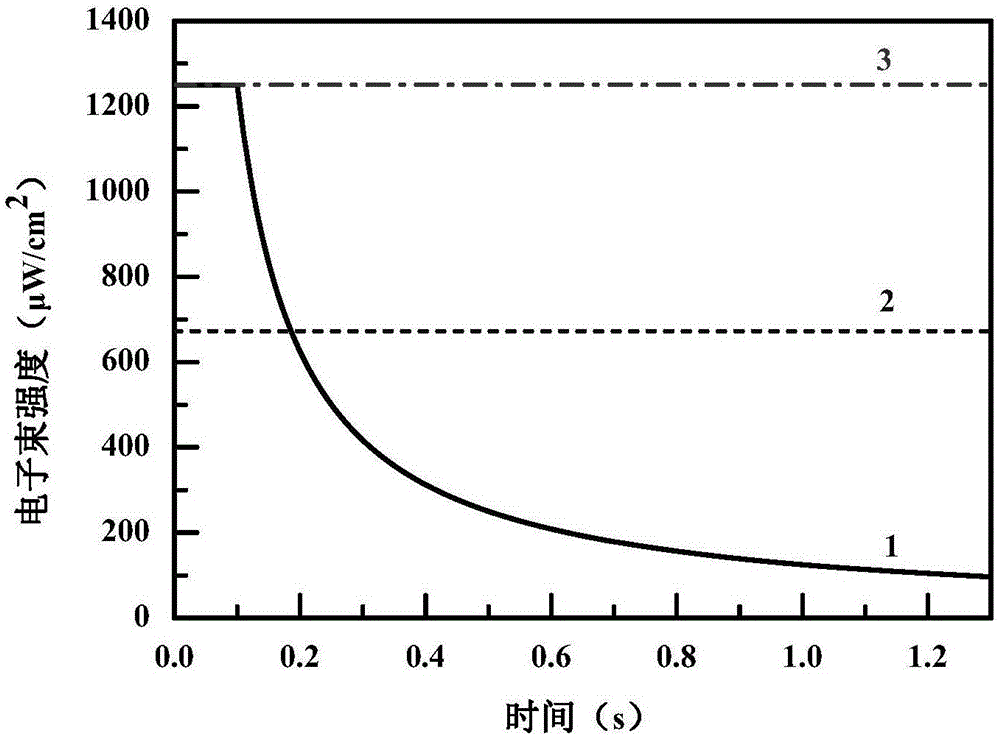

Gradual intensity electron beam radiation coating solidification process

ActiveCN106475286AImprove curing efficiencyReduce energy consumptionPretreated surfacesAnti-corrosive paintsHigh energyUltimate tensile strength

The invention discloses a gradual intensity electron beam radiation coating solidification process. The invention bases on the solidification technics of electron beam radiation, adopts a solidifying form of gradual intensity, and mainly is used for solidifying coating with thickness at 100Mum-500Mum, the electron beam intensity is accurately controlled by a computer program, and achieves a dynamic coordination with the solidified thickness of the coating. On one hand, the process bases on the solidification of electron beam radiation, solves the problems of high energy consumption and inadequate depth by solidifications of traditional ultraviolet ray, one the other hand, the process adopts a solidifying form of gradual intensity, respectively solidifies the surface and the insides of the coating, further solves the problem of unenven solidifications of an inside and outside layer membrance when intermittently solidifying ultraviolet-electron beam, thereby increases the direct adherence force of the coating and a base material, enables the coating to possess superior abrasion tolerance and anti erosion property, meanwhile the process reduces unnecessary energy consumption when solidifying the electron beam at a single intensity. The obtained coating from the provided solidification process can be applied to the field of metal corrosion repreventions, meanwhile can achieve the coating and dressing of rusty surfaces.

Owner:YIXING HONGTAI CHEM +1

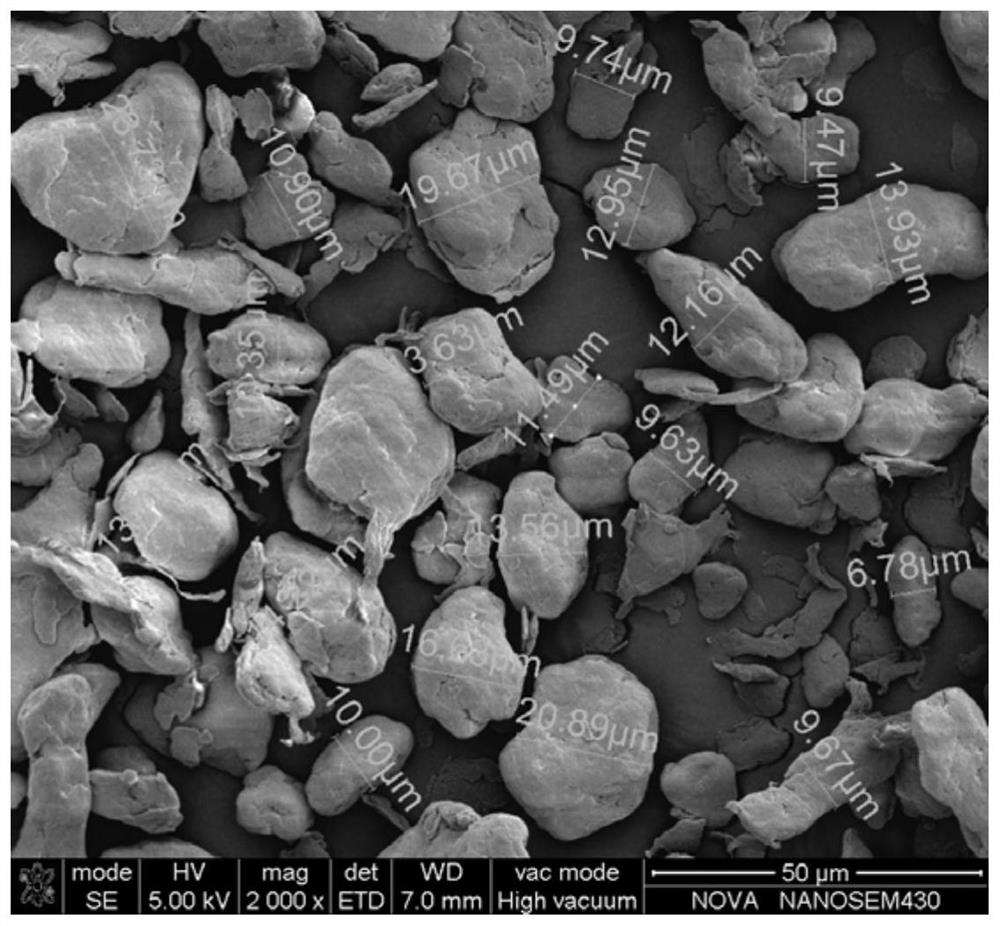

Cement-based pollutant-blocking grouting material and preparation method thereof

ActiveCN113480284AGuaranteed permeabilityTake into account the tightnessCeramicwareZerovalent ironSlurry

The invention belongs to the fields of grouting technology of mines and underground sewage treatment, and provides a cement-based pollutant-blocking grouting material and a preparation method thereof. The cement-based pollutant-blocking grouting material comprises 40-50% of cement, 32-40% of water, 2-5% of calcium oxide, 10-15% of an active filler, 1-2% of gas-forming coated particles, 8-13% of sodium silicate, 1-2% of basalt fibers, 0.5-1% of guar gum, and 0.1-0.5% of sodium dodecyl sulfate, wherein the gas-forming coated particles are aluminum powder particles with kerosene isolating layers, and the active filler is selected from zero-valent iron, magnetite and activated carbon. The material can be used for reinforcing a roadway and inhibiting diffusion of underground pollutants in a mining area at the same time; the material can be injected into potential water passing channels around a mine in advance through a grouting technology; when the material reaches a designated place, dense fine bubbles can be rapidly generated in the material, the whole slurry is rapidly hydrated and expanded, and strength is obtained; and after mining is finished, the level of underground water rises to carry pollutants in a mining area into the underground water, and the material can block migration of the pollutants through a large specific surface area of a porous structure and active substances contained in the material.

Owner:SHANDONG UNIV +1

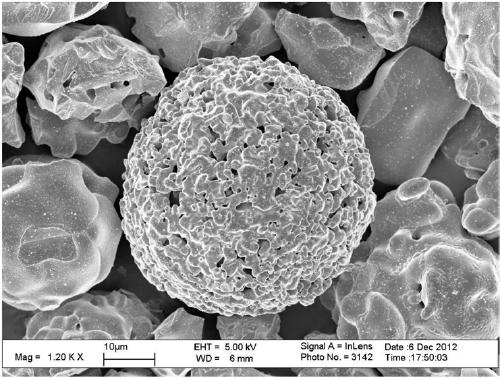

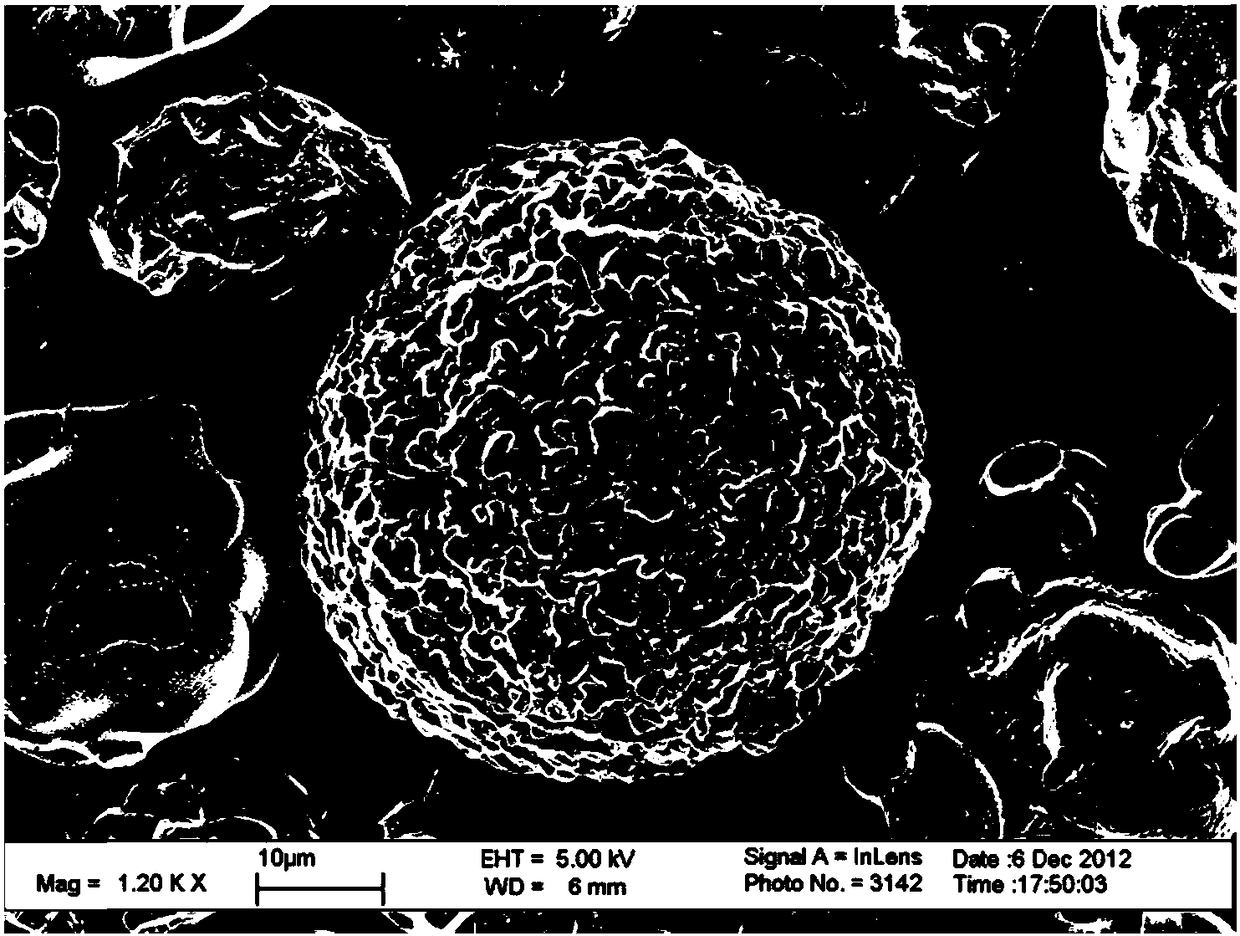

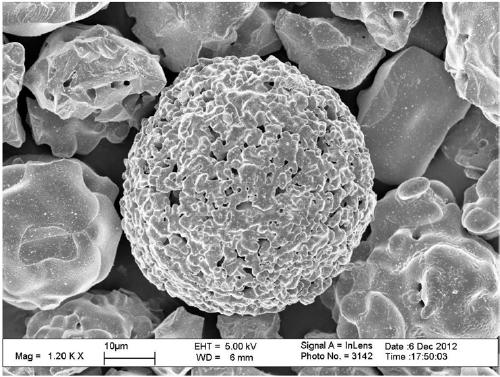

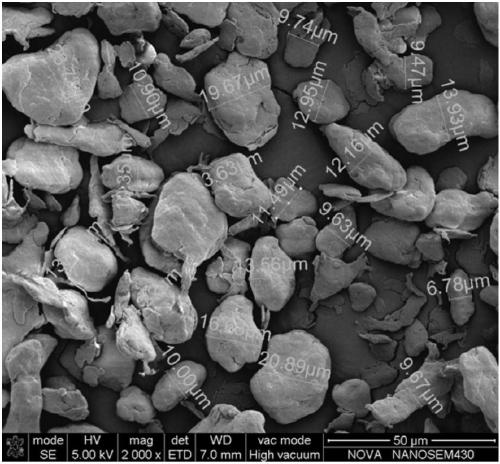

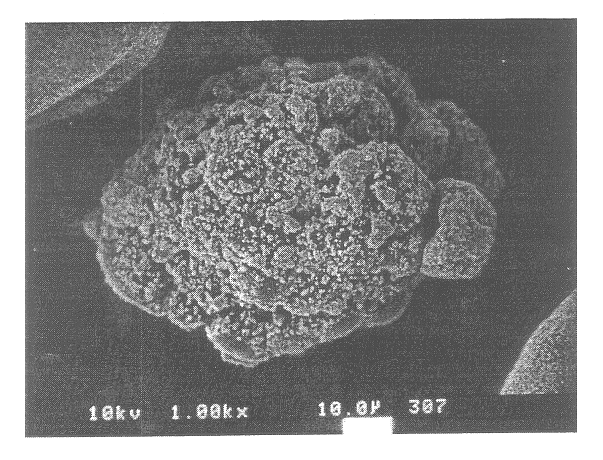

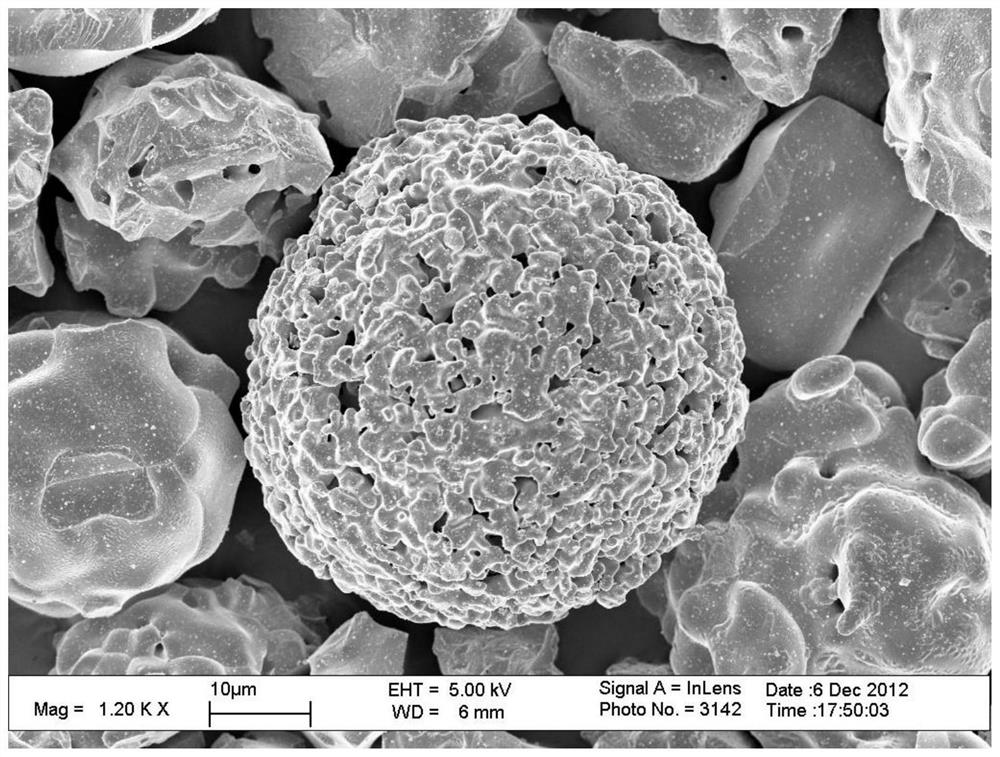

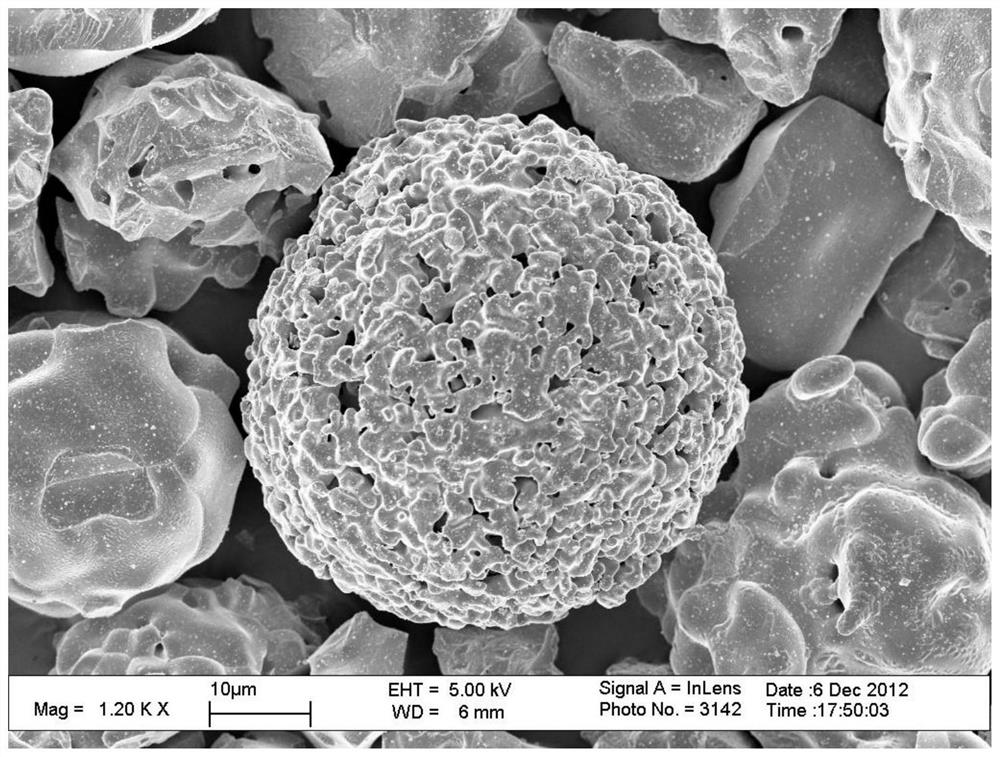

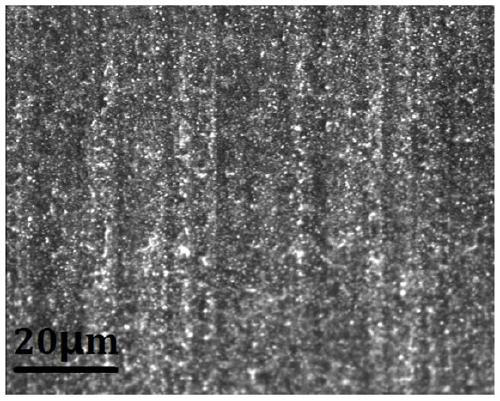

Ceramic shell thermal spray powders and methods of use thereof

InactiveUS6602556B2Large coating thicknessImprove adaptabilityMolten spray coatingPretreated surfacesCeramic coatingMetallurgy

Owner:SAINT GOBAIN ABRASIVES INC

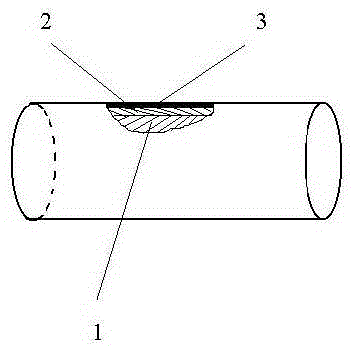

Continuous vacuum electron beam coating method

InactiveCN109295417ALarge coating thicknessLow costVacuum evaporation coatingSputtering coatingWinding machineElectron

The invention discloses a continuous vacuum electron beam coating method and belongs to the technical field of coating. The invention aims to provide a method of coating a thick film with low cost, nopollution, high efficiency and high quality. The method comprises the following steps: putting a coated metal in a continuous vacuum electron beam coating device, wherein a substrate material operates in an electron beam furnace through an uncoiler and a winding machine; heating the substrate material to 400-1200 DEG C; and setting the electron beam power to be not smaller than 20 KW and controlling the vacuum degree of the working chamber of the electron beam furnace at 10-10<-3>Pa to coat, and cooling the coated film to be not higher than 300 DEG C to obtain the coated composite material. The method can be used for obtaining corrosion-resistant coated composite material which is large in coated thickness and has the characteristics of being low in cost, pollution-free, high in speed andhigh in efficiency.

Owner:PANZHIHUA UNIV +1

Epoxy vinyl ester micro compound resin and preparing method thereof

InactiveCN106349889AReduce resin contentLarge coating thicknessAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsChemistry

The invention relates to an epoxy vinyl ester micro compound resin and preparing method thereof. The resin is characterized by that epoxy vinyl ester micro compound resin mainly comprises epoxy vinyl ester resin, quartz sand, dispersant, defoaming agent and leveling agent. The preparing method of epoxy vinyl ester micro compound resin comprises the following step: (1) Weighting raw materials according to claim 2 formula; (2) mixing and stirring raw materials after the raw materials are added into mixing tank; (3) adding the raw materials into high-speed dispersing machine for dispersion; (4) adding the raw materials into grinding miller for grinding; (5) packaging all raw materials in different packages and placing them in cool and dry place for later use. In the preparing method, high-speed dispersing can mix the chemical materials with quartz powder completely and evenly, grinding can open the particles of original resin to make the particles form a new combination with the high-speed dispersed mixture which is added later, in order to form epoxy vinyl ester micro compound resin.

Owner:南丹县南方有色金属有限责任公司

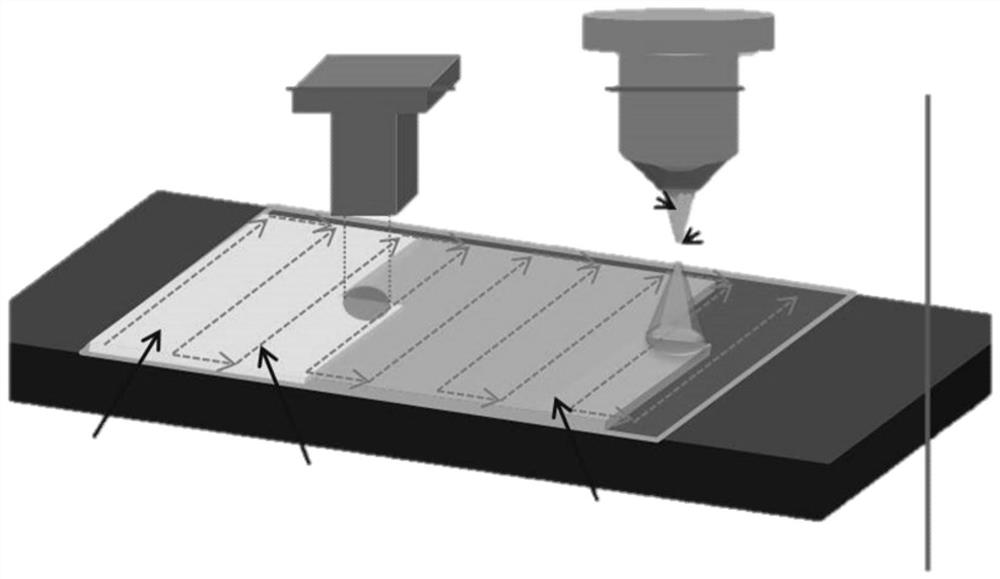

Method for preparing reignition turbine first-stage work bladetip wear-resistant coating

InactiveCN101705487BImprove wear resistanceImprove automation control levelMetallic material coating processesAutomatic controlLaser coating

The invention discloses a method for preparing a reignition turbine first-stage work bladetip wear-resistant coating, which comprises the following steps of: (1) scanning the edge of the end face of the bladetip by using an infrared scanning device of laser coating equipment to enable a scanning track program control program to record the position of a scanned point; and (2) starting a laser generator of the laser coating equipment, transferring alloy powder to the end face of the bladetip under the protection of inert gases, and melting the alloy powder with laser beams. The matrix material of the reignition turbine first-stage work blade is a nickel-based cast high-temperature alloy K488 and the alloy powder is Co-based self-fusing alloy powder. The method for preparing the coating improves the high-temperature wear resistance of the coating, also improves automatic control level and production efficiency of the coating preparation and guarantees the stability of the quality of the product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

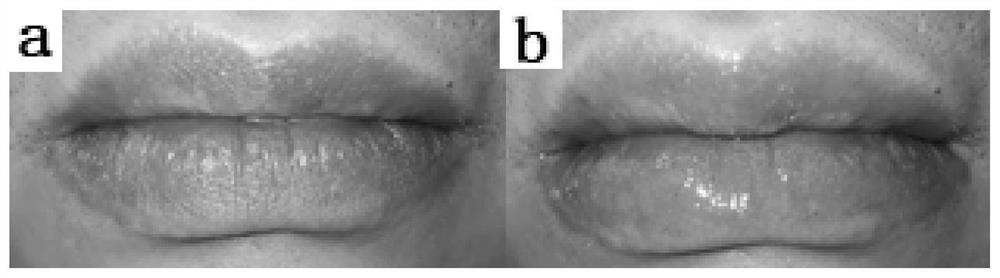

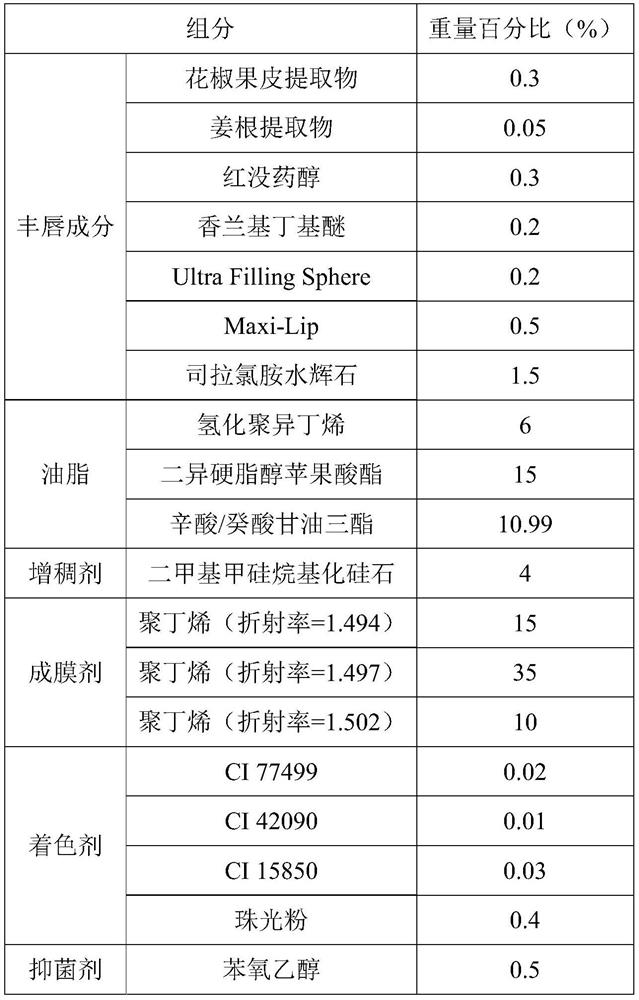

Lip enlarging glaze containing pricklyash peel extract and preparation method of lip enlarging glaze

PendingCN111821247AIncrease brightnessPromote blood circulationCosmetic preparationsMake-upMedicineCapsaicin

The invention relates to lip enlarging glaze containing prickly ash peel extract and a preparation method of the lip enlarging glaze. The lip enlarging glaze comprises the following components: a lipenlarging component, grease, a thickening agent, a bacteriostatic agent and a film-forming agent, wherein the lip enlarging component comprises the prickly ash peel extract. The lip enlarging glaze provided by the invention contains the lip enlarging component containing the prickly ash peel extract, and prickly ash as a rutaceous plant is rich in unsaturated fatty acid, can improve hemorheology,is usually used in edible seasonings, and is natural and edible. The fruit peel extract is mild and safe when being used on the skin, and does not cause strong burning feeling like capsaicin. The prickly ash peel extract is added into the lip enlargement product for the first time, and the instant lip enlargement effect is achieved by enhancing blood circulation of the lip.

Owner:广州那比昂生物科技有限公司

Method and coating system for coating cavity walls

ActiveCN107209010AReduce mistakesLarge coating thicknessLiquid surface applicatorsMolten spray coatingVariable thicknessCoating system

The invention relates to a method for coating cavity walls, in particular cylinder bores of engine blocks. In the method, a coating is applied to a cavity wall using a coating lance. In addition, a cavity diameter is measured using a measuring apparatus. According to the invention, the method is characterized in that at least a plurality of diameter values of a first cavity are measured at different heights of the first cavity using the measuring apparatus, and in that a coating of variable thickness is applied to a wall of the first or a second cavity using the coating lance, the thickness of said coating of variable thickness being dependent on the determined diameter values. The invention additionally describes a corresponding coating system.

Owner:STURM MASCH & ANLAGENBAU GMBH

Method and coating system for coating cavity walls

ActiveCN107209010BLarge coating thicknessLiquid surface applicatorsMolten spray coatingCoating systemCylinder block

The invention relates to a method for coating the walls of a cavity, in particular the cylinder bore of an engine block. In this method, a coating is applied to the cavity walls with a coating gun. In addition, a measuring device is used to measure the cavity diameter. According to the invention, the method is characterized in that at least a plurality of diameter values of the first cavity are measured at different heights of the first cavity with a measuring device, and that the wall of the first cavity or the second cavity is measured with a coating spray gun. A variable-thickness coating is provided, the thickness of which depends on the determined diameter value. In addition, the present invention also describes a corresponding coating system.

Owner:STURM MASCH & ANLAGENBAU GMBH

Non-stick coating and method for its preparation, as well as pots and cooking equipment

ActiveCN108977747BHigh hardnessHigh bonding strengthCooking-vessel materialsMolten spray coatingCarbide siliconPowder mixture

The invention relates to the technical field of electric heating appliances, and discloses a non-stick coating, a preparation method thereof, pots and cooking equipment. The method comprises: (1) pretreating the substrate; (2) preheating the surface of the substrate obtained in step (1); (3) mixing silicon carbide powder and fluororesin powder to obtain a powder mixture, and The powder mixture is plasma sprayed to form a non-stick coating on the substrate surface. The non-stick coating of the present invention is gray-black, stain-resistant, and has high surface hardness, high coating bonding force, good scratch resistance, good corrosion resistance, good wettability, good heat transfer performance, and long service life Etc.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

A kind of electron beam radiation curing coating for metal heavy anticorrosion

ActiveCN106433258BImprove curing efficiencyReduce energy consumptionAnti-corrosive paintsBeam energyOligomer

The invention discloses an electron beam radiation curing coating for metal heavy anti-corrosion. The coating is prepared from, by mass, 50%-80% of oligomer, 0.1-0.5% of reactive diluent, 1-10% of functional filler, 5-20% of antirust dyestuff and 5-15% of auxiliary filler, and the total mass percentage of the components is 100%. The curing coating for metal heavy anti-corrosion is cured by electron beam radiation, has the advantages of high efficiency and energy conservation, environment friendship and convenient operation, cured depth of the coating is high, thickness is big, and the adhesive force between the coating and the substrate is strong. A conductive carbon material is doped in the curable coating, thus the problem of metal heavy anti-corrosion is solved while electron beam energy absorption is avoided, and it is guaranteed that cured efficiency is not affected. The electron beam radiation curing coating for metal heavy anti-corrosion has excellent wear-resistance and corrosion-resistance, can be applied to the field of metal heavy anti-corrosion anti-corrosion, and is particularly applicable to the field of maritime work heavy anti-corrosion.

Owner:NANJING INST OF TECH +1

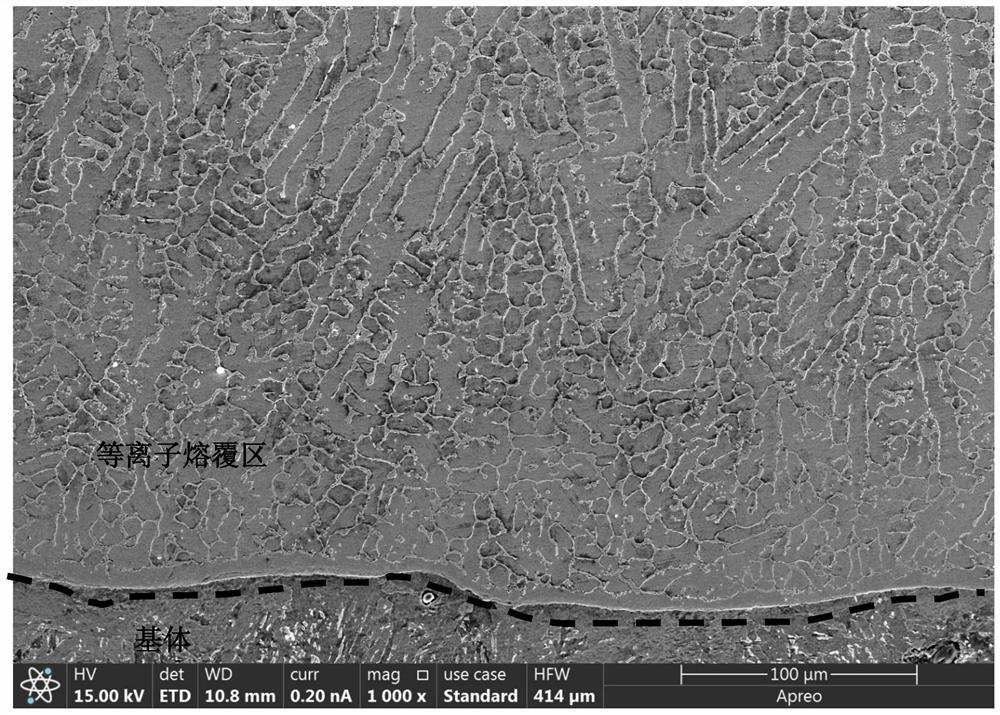

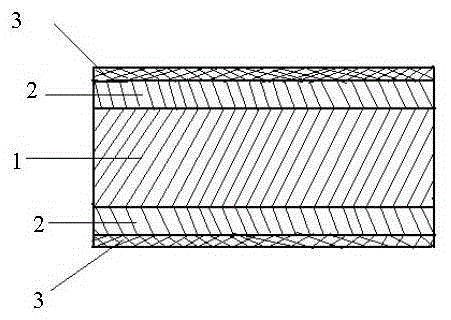

A corrosion-resistant and wear-resistant coating with a gradient combination structure and its preparation method

ActiveCN113122841BSmall plasticityGood plasticityMetallic material coating processesHigh entropy alloysCrystal structure

The invention discloses a corrosion-resistant and wear-resistant coating with a gradient combination structure and a preparation method thereof, which is to clad alloy powder on the surface of a pretreated substrate by plasma cladding to obtain an alloy layer with a large thickness dendritic structure. Afterwards, the surface of the alloy layer is remelted by laser without feeding powder, and the growth of thick dendrites is fused to obtain a fine equiaxed crystal structure. After the plasma cladding of the present invention, a thick dendrite structure is formed. The dendrite has a peg effect on the substrate, and has a supporting effect on the subsequent laser high-speed cladding layer, which ensures the large-thickness coating, strengthens the combination with the substrate, and melts with high entropy. The alloy powder is fully and evenly mixed. The subsequent laser remelting can melt the thick dendrites and obtain fine and dense equiaxed crystals, which can block the propagation of corrosive media and improve corrosion resistance.

Owner:OCEAN UNIV OF CHINA

Vacuum electron beam coating method

InactiveCN109267017ALarge coating thicknessIncrease diversityVacuum evaporation coatingSputtering coatingElectronElectron-beam furnace

The invention belongs to the technical field of coating, relates to a vacuum electron beam coating method and aims to provide a low-cost, pollution-free, high-efficiency and high-quality thick coatingmethod. The method in which vacuum electron beam coating is adopted includes steps: adding coating metal into a vacuum electron beam coating device, taking an iron-base material as a substrate material, heating the substrate material to 400-1200 DEG C, setting electron beam power to be not smaller than 20KW, controlling a vacuum degree of an operating cavity of an electron beam furnace in a rangeof 10-10<-3>Pa, coating, and cooling to 300 DEG C or below to obtain a coating composite material. By adoption of the vacuum electron beam coating method, the coating composite material high in coating thickness and resistant to corrosion can be obtained, and low cost, freeness of pollution, high speed and high efficiency are realized.

Owner:PANZHIHUA UNIV +1

Non-stick coating and method for its preparation, as well as pots and cooking equipment

ActiveCN108977748BImprove performanceGood hydrophobic self-cleaning propertyCooking-vessel materialsMolten spray coatingOxide ceramicPowder mixture

The invention relates to the technical field of electric heating appliances, and discloses a non-stick coating, a preparation method thereof, pots and cooking equipment. The method comprises: (1) pretreating the substrate; (2) preheating the surface of the substrate obtained in step (1); (3) mixing metal oxide powder and fluororesin powder to obtain a powder mixture, and The powder mixture is thermally sprayed to form a non-stick coating on the surface of the substrate, and the metal oxide powder includes aluminum oxide powder and tetravalent metal oxide ceramic powder. The non-stick coating of the invention has the advantages of high surface hardness, high coating binding force, good scratch resistance, good corrosion resistance, good wettability, long service life and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

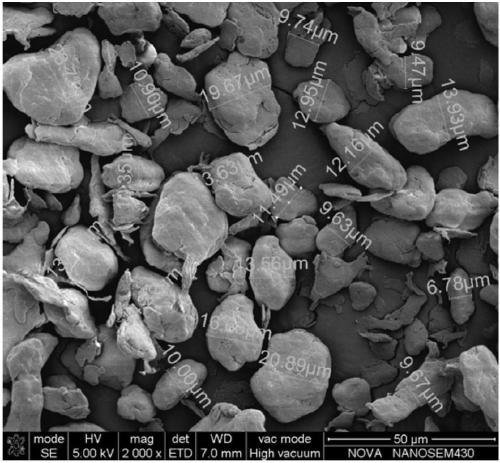

Polyurethane prepolymer, polyurea material, preparation method and application thereof

ActiveCN107522842BIncrease filling volumeLarge coating thicknessPolyurea/polyurethane coatingsRadiation-absorbing paintsPolyesterPolymer science

The invention provides a polyurethane prepolymer, polyurea material and preparation methods and applications thereof and belongs to the field of high-polymer materials. The preparation method of the polyurethane prepolymer comprises mixing polyopolyols and micro-branched polyester polyols in a reaction container, eliminating water under vacuum, and then adding toluene diisocynate and solvent into the reaction container for reaction at 70-80 DEG C for 3-4 h. The preparation method of the polyurea material comprises mixing diamine, antioxygen and mixture solvent to obtain a mixture and mixing the polyurethane prepolymer with the mixture at a weight ratio of 100:23-45. The polyurea material is high filling amount of iron-based powder, large in coating thickness, high in adhesion force, good in flexibility and high in impact resistance.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Method for preparing carbon material surface ceramic coat

The invention relates to a method for preparing a carbon material surface ceramic coat, which comprises the following steps of: uniformly coating the prepared slurry on a carbon material matrix with the coating thickness of 0.8 to 1.2 millimeters, and drying the carbon material matrix to form a uniform coating material on the carbon material matrix; performing TIG deposition on the coating material coated on the carbon material matrix under the process parameters that the current is 120 to 160A, the electric arc voltage is 15 to 20V, the deposition speed is 6 to 8m / h and the argon flow is 5-8L / min so as to melt the coating material under the action of electric arc heat, and cooling the carbon material matrix to obtain a ceramic layer tightly combined with the matrix on the carbon materialmatrix. The method has the advantages of simple operation, high efficiency, low cost, attractive coat and metallurgical combination with the matrix. The prepared ceramic coat has controllable component, high thickness, oxidization resistance and ablation resistance.

Owner:HARBIN INST OF TECH AT WEIHAI

A method for enhancing the surface of metal rolls by electrospark deposition combined with plasma cladding

InactiveCN103805934BImprove heat resistanceImprove wear resistanceMolten spray coatingElectric dischargePlasma deposition

The invention relates to a method for strengthening a surface of a metal roller by adopting an electro-spark deposition method and a plasma fusion covering method. The metal roller is processed in an electro-spark deposition way and a plasma fusion covering way, so that the problems for improving the hardness, abrasion resistance and impact resistance of the surface of the roller and prolonging the service life of the metal roller can be effectively solved. The method comprises the following steps: performing fusion covering of alloy powder onto the surface of the roller by utilizing non-oxidized plasma beam to form a molten alloy coating, depositing WC ceramic hard alloy by utilizing the electro-spark deposition way on the basis of the plasma fusion covering coating to form a composite coating integrating the electro-spark deposition and plasma fusion covering. The method is simple and practical, the electro-spark deposition and the plasma fusion covering composite coating is firmly combined with a substrate, the thickness of the coating is large, so that the surface hardness, compactness, heat resistance and abrasion resistance of the roller are good, and the service life is long; by adopting the composite coating, the price of the iron-nickel alloy powder is low, the thickness of the coating is large, the abrasion resistance and corrosion resistance are good, the hardness and strength are high, and the abrasion and heat resistance is excellent.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

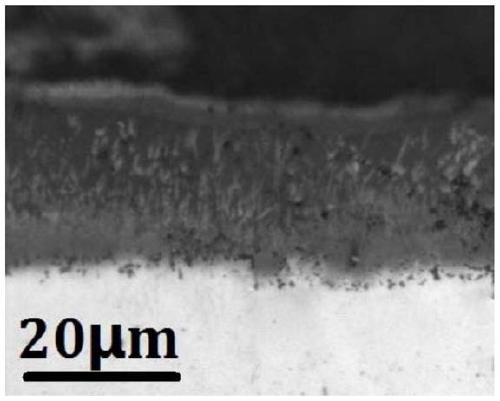

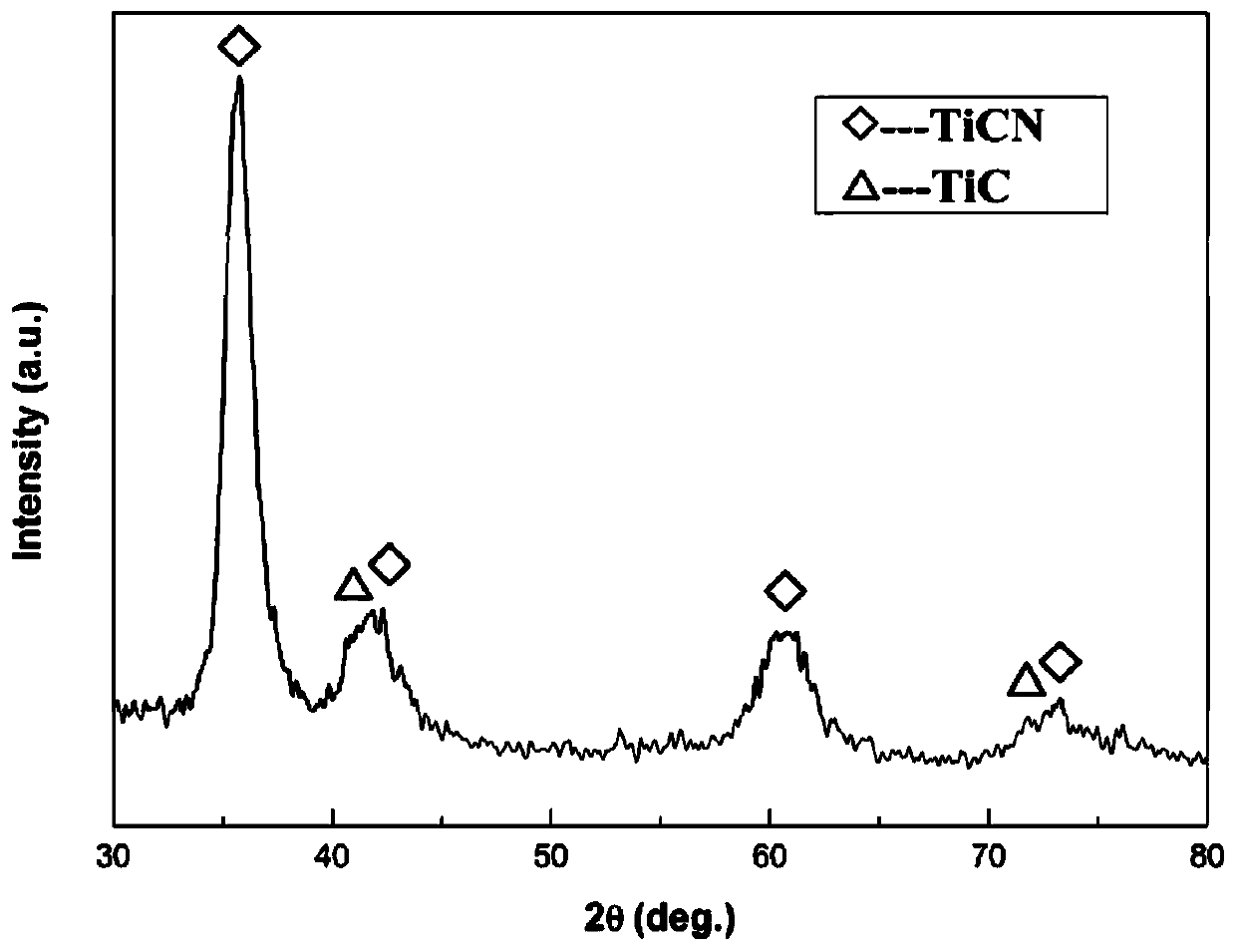

A method for in-situ preparation of TICN coating on the surface of titanium alloy

The invention discloses a method for preparing a TiCN coating layer in situ on the surface of titanium alloy. The method comprises the following steps: mechanically cleaning the surface of a titaniumalloy workpiece until the surface roughness of the titanium alloy workpiece is smaller than 3.2 microns, and uniformly smearing the titanium alloy workpiece with a layer of vaseline paste; and (2) putting the region, smeared with the vaseline paste, of the titanium alloy workpiece below a pulse YAG laser under the protection of nitrogen atmosphere, switching on a power supply of the pulse YAG laser to realize laser irradiation on the region, smeared with the vaseline paste, of the titanium alloy workpiece, and finally cleaning and airing, so as to obtain the TiCN coating layer on the surface of the titanium alloy workpiece. The method is simple, the thickness of the TiCN coating layer is mainly controlled according to the thickness of the smeared vaseline paste and the laser power, and thevaseline paste is taken as a carbon source, so that the cost is low, a process microcell environment can be isolated during the reaction on the surface, and the surface oxidation of the titanium alloy can be prevented.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A hot extrusion die permeation-plating compound surface strengthening method

InactiveCN104911552BReduce hardnessMake up for the lack of performanceVacuum evaporation coatingSputtering coatingPower flowService condition

The invention discloses a method for reinforcing a surface of a hot-extrusion die through cementation compounding. The method comprises the following steps: polishing and cleaning the surface of a die subjected to nitriding treatment, and performing CrAlN coating processing in arc ion plating equipment; with a rectangular Ti target as a Ti source of a bottom layer and a transition layer, controlling the sputtering rate of the rectangular Ti target through the current of the arc power of the rectangular target; with a circular CrAl target as the Cr and Al element source of a CrAlN coating, controlling the sputtering rate of the circular CrAl target through the current of the arc power of the circular CrAl target; ionizing high-purity Ar and N2 so as to be combined with Cr and Al elements, and depositing on the nitriding layer of the die to form the CrAlN coating. The method disclosed by the invention is applicable to the field of hot-extrusion dies in high-temperature and heavy-load harsh service conditions.

Owner:XI AN JIAOTONG UNIV

Vacuum electron beam double-roller pressing coating method

InactiveCN109267011AImprove joint forceLarge coating thicknessVacuum evaporation coatingSputtering coatingPollutionElectron

The invention belongs to the technical field of coating, relates to a vacuum electron beam double-roller pressing coating method and aims to provide a low-cost, pollution-free, high-efficiency and high-quality thick coating method. The method in which vacuum electron beam double-roller pressing coating is adopted includes steps: adding a coating material into a vacuum electron beam double-roller pressing coating device, heating a substrate material to 400-1200 DEG C, setting electron beam power to be not smaller than 20KW, controlling a vacuum degree of an operating cavity of an electron beamfurnace in a range of 10-10<-3>Pa, coating, performing double-roller pressing in a coating process, and cooling to 300 DEG C or below to obtain a coating composite material. By adoption of the vacuumelectron beam double-roller pressing coating method, the coating composite material high in coating thickness and jointing force and resistant to corrosion can be obtained, and low cost, freeness of pollution, high speed and high efficiency are realized.

Owner:PANZHIHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com