Vacuum electron beam double-roller pressing coating method

A vacuum electron beam and electron beam technology, which is applied in the field of vacuum electron beam to roll press coating, can solve the problems of difficult explosive welding quality and difficult compounding of titanium steel, and achieve the effect of large bonding force, large coating thickness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

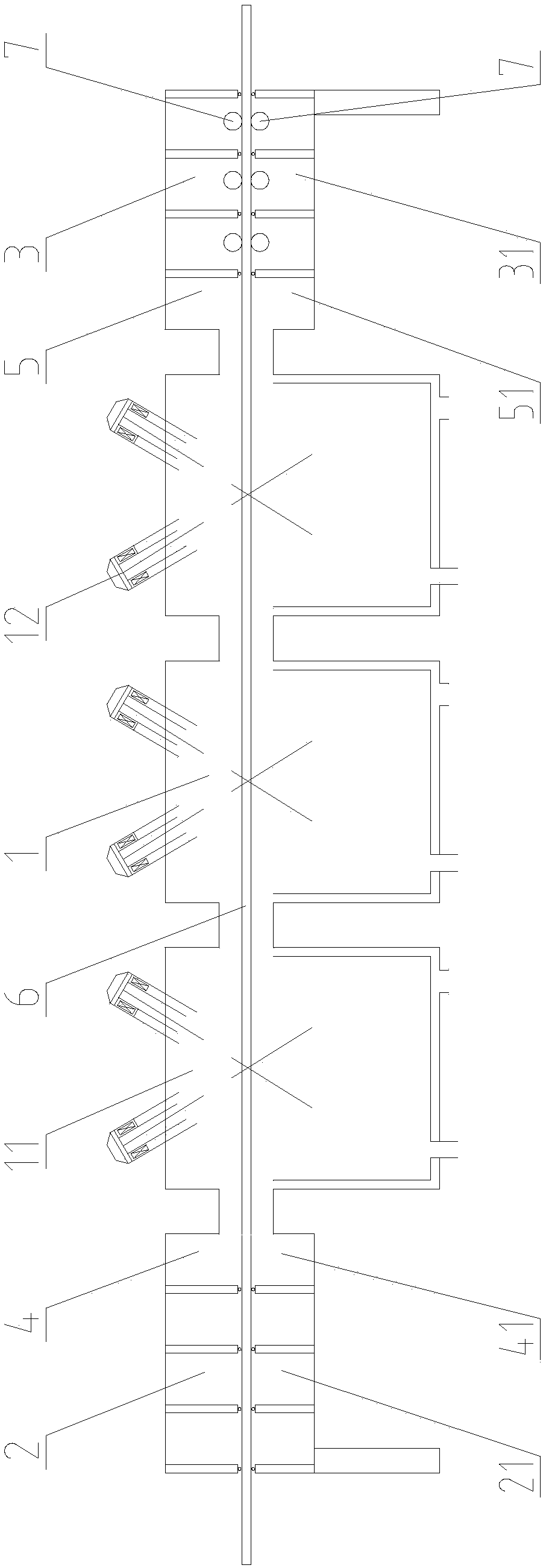

[0049] In the vacuum electron beam-to-roll coating device of the present embodiment:

[0050] The electron beam furnace contains 1 working chamber, and each working chamber is equipped with 2 electron guns;

[0051] There are 3 vacuum chambers in front of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum heating device for multi-stage heating;

[0052] There are 3 vacuum chambers in the front or back of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum device for multi-stage vacuum;

[0053] Two pairs of rollers are installed in the rear vacuum chamber of the vacuum electron beam roller coating device. The pressure parameter of the first pair of rollers is set to 0.05MPa, and the pressure parameter of the second pair of rollers is set to 0.1MPa for multi-stage roller pressing. ;

[0054] There are 3 vacuum chambers behind the vacuum electron beam coating device, and each vacuum chambe...

Embodiment 2

[0058] In the vacuum electron beam-to-roll coating device of the present embodiment:

[0059] The electron beam furnace contains a working chamber, and the working chamber is equipped with 2 electron guns;

[0060] There are 4 vacuum chambers in front of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum heating device for multi-stage heating;

[0061] There are 3 vacuum chambers in the front or back of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum device for multi-stage vacuum;

[0062] Set 4 pairs of rollers in the rear vacuum chamber of the vacuum electron beam roller coating device, the pressure parameter of the first pair of rollers is 0.1MPa, the pressure parameter of the second pair of rollers is 0.2MPa, the third pair of rollers Set the pressure parameter to 0.5MPa, set the pressure parameter of the fourth pair of rollers to 1MPa, and perform multi-stage roller pressing;

...

Embodiment 3

[0067] In the vacuum electron beam-to-roll coating device of the present embodiment:

[0068] The electron beam furnace contains a working chamber, and the working chamber is equipped with 2 electron guns;

[0069] There are 3 vacuum chambers in front of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum heating device for multi-stage heating;

[0070] There are 3 vacuum chambers in the front or back of the vacuum electron beam coating device, and each vacuum chamber is equipped with a flat vacuum device for multi-stage vacuum;

[0071] Set 3 pairs of rollers in the rear vacuum chamber of the vacuum electron beam roller coating device, the pressure parameter of the first pair of rollers is 1MPa, the pressure parameter of the second pair of rollers is 2MPa, and the pressure parameter of the third pair of rollers 3MPa, multi-stage roller pressing;

[0072] There are 3 vacuum chambers behind the vacuum electron beam coating device, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com