Light modulator and its fabrication method

一种光调制器、制造方法的技术,应用在仪器、光学、非线性光学等方向,能够解决基板与导电膜接合力弱、导电膜与基板易剥离、光波散射或吸收等问题,达到抑制共振现象或热电效果、抑制热电效果、抑制剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be described in detail using appropriate examples.

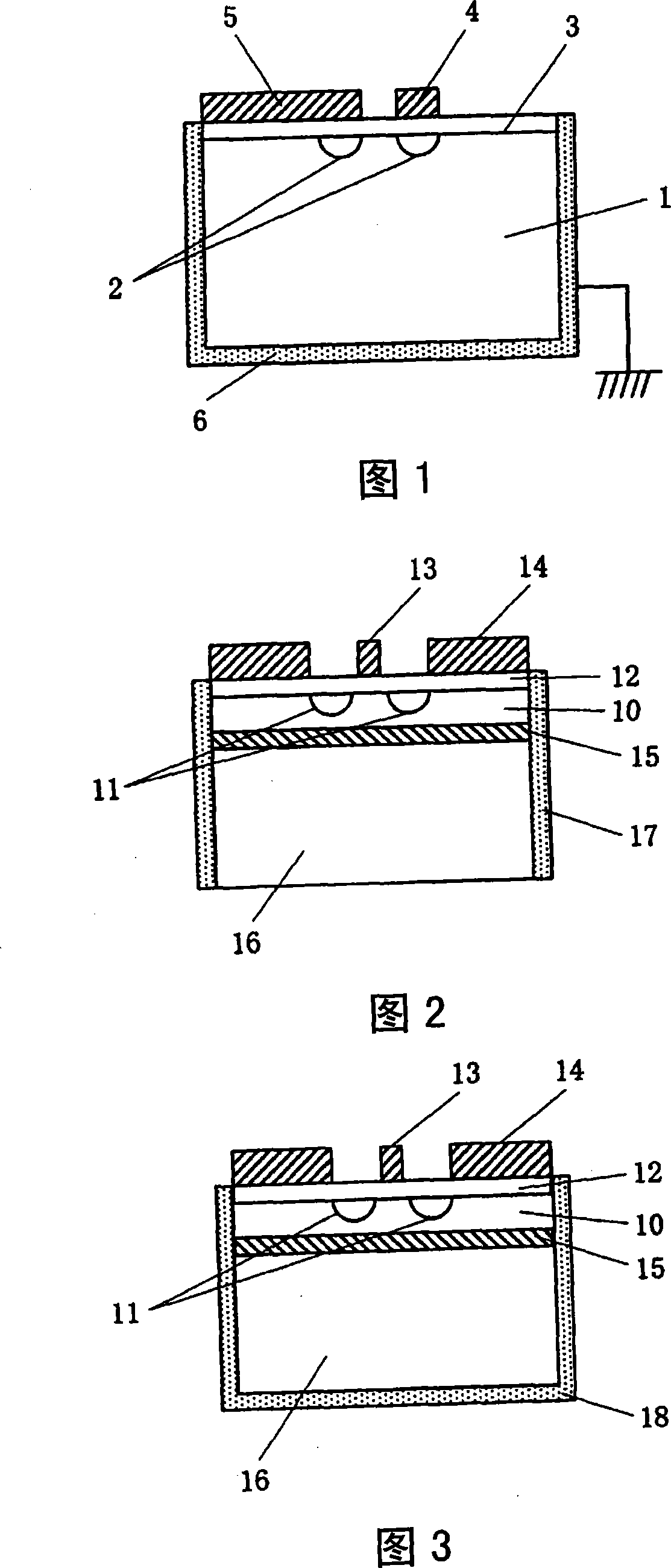

[0048] FIG. 2 is a diagram showing a first embodiment of an optical modulator according to the present invention, showing a cross-sectional view of the optical modulator.

[0049] The light modulator includes: a thin plate 10 with a thickness of 20 μm or less formed of a material having an electro-optical effect; an optical waveguide 11 formed on the surface of the thin plate (the optical waveguide may also be formed on the back of the thin plate 10); and a modulation electrode (signal electrode 13, ground electrode 14), which are formed on the surface of the thin plate, and are used to modulate the light passing through the optical waveguide; the above-mentioned optical modulator is characterized in that it has: a reinforcing plate 16, which is bonded through the layer 15, which is bonded on the back of the thin plate; and a conductive film 17, which is formed continuously from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com