Socket connector

A technology of socket connectors and plug connectors, which is applied in the direction of connection, conductive connection, parts of connection devices, etc., can solve the problems that the connection structure of plug connectors and socket connectors cannot be flattened and the height becomes higher, and achieve Improve connection reliability, increase strength, and achieve flattening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

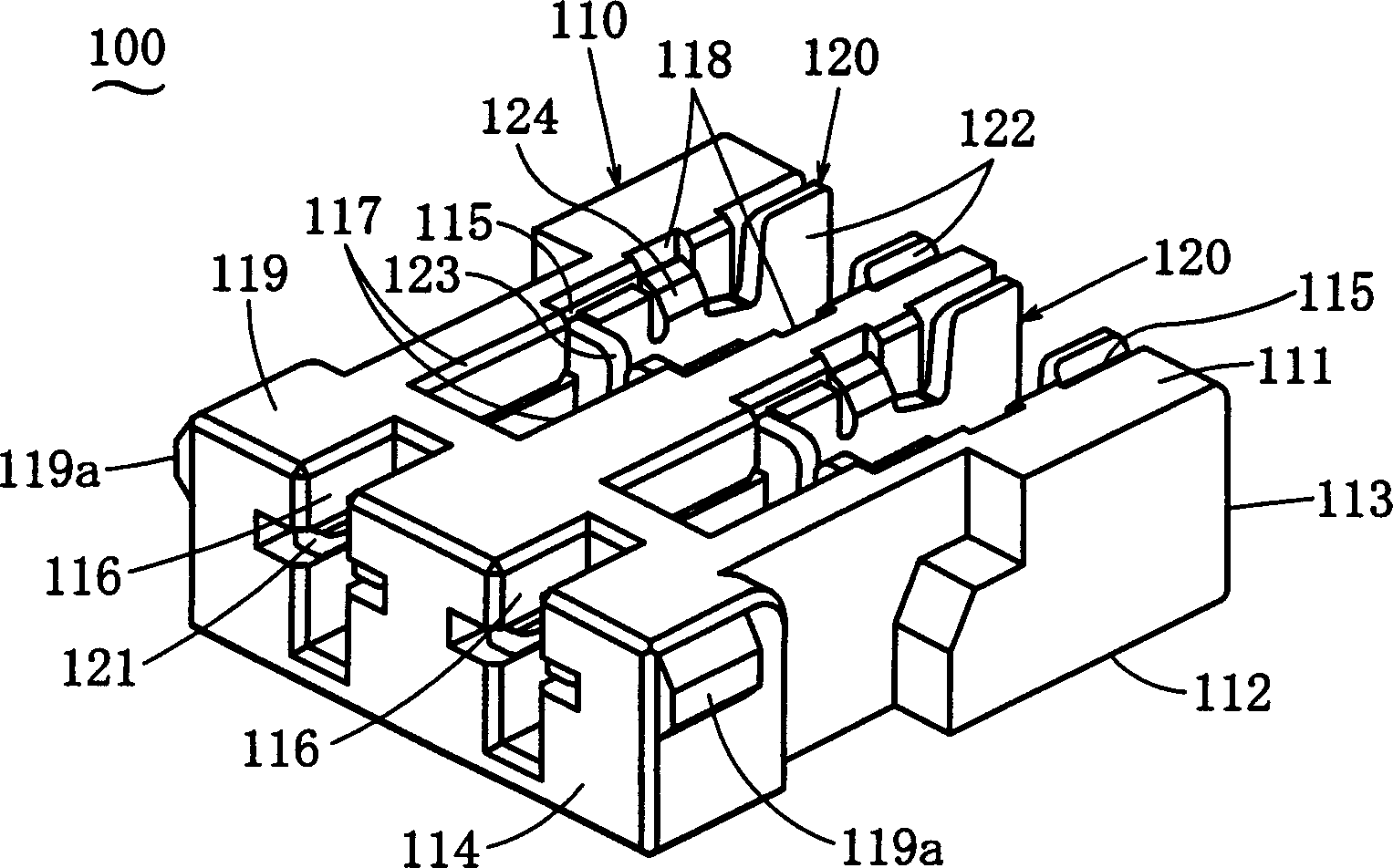

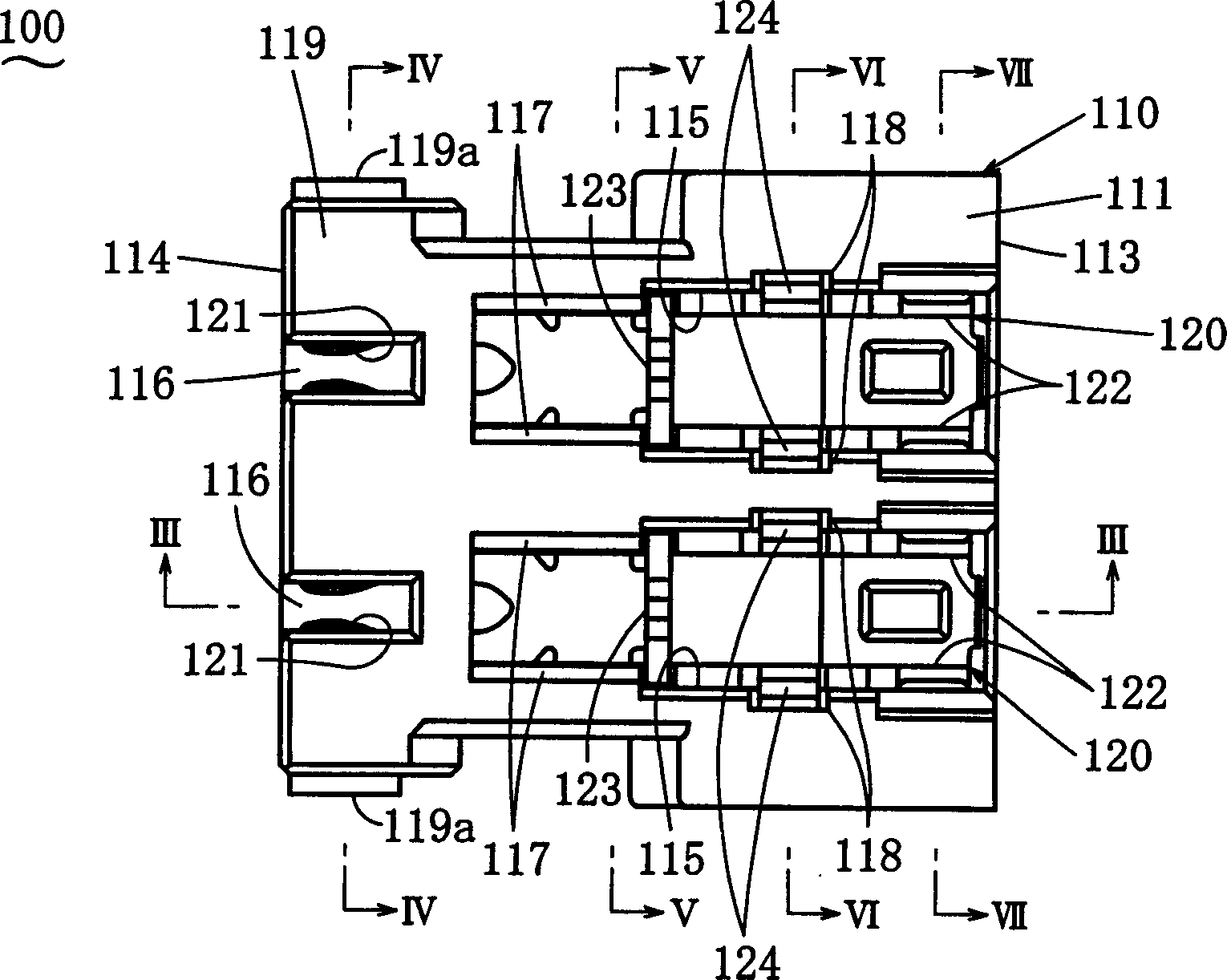

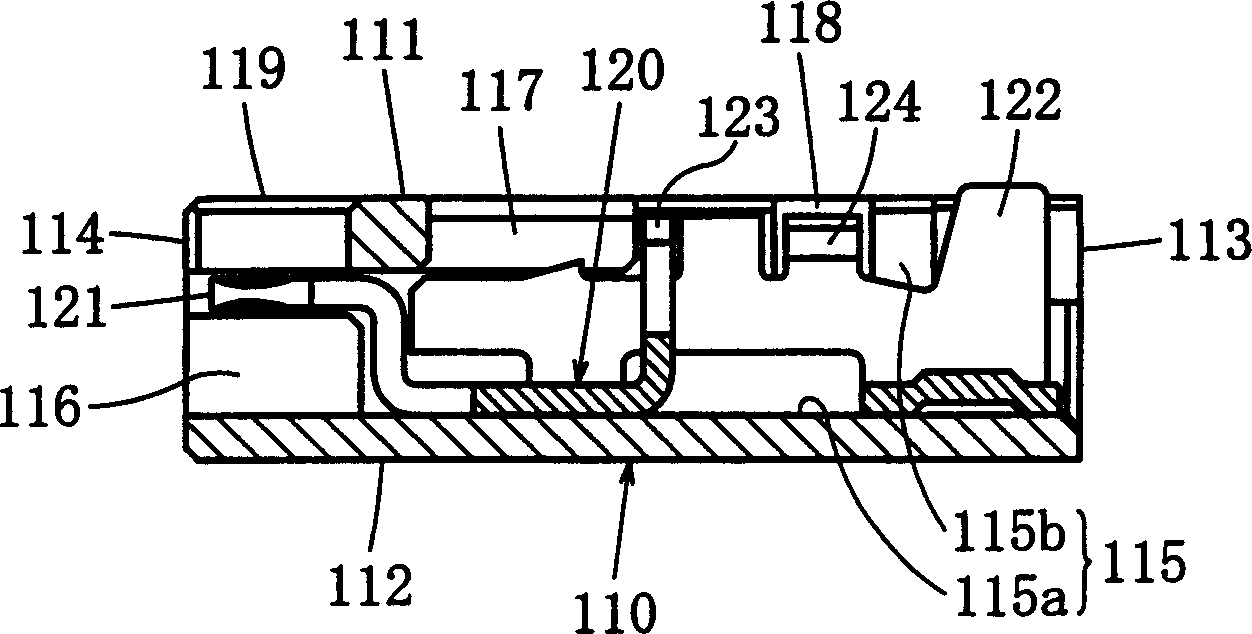

[0034] Hereinafter, examples of the present invention will be described. Figure 1 to Figure 7 Receptacle connector 100 of an embodiment of the present invention is shown. The directions perpendicular to each other are assumed to be the longitudinal direction, the width direction, and the height direction, and the description will be made with reference to these directions. For the case of this example, if combined with figure 2For description, the left-right direction in the figure is the vertical direction, the left side in the figure shows the depth in the vertical direction, and the right side in the figure shows the front in the vertical direction. In addition, a direction perpendicular to the paper surface of the drawing indicates a height direction, and an up-down direction in the drawing indicates a width direction. The receptacle connector 100 has: a receptacle housing 110 formed of an insulating material; and receptacle contacts 120 formed of a conductive material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com