Non-stick coating and preparation method thereof as well as pot and cooking equipment

A non-stick coating and pot technology, applied in coatings, household appliances, kitchen utensils, etc., can solve the problems of high pre-treatment requirements, short service life, low hardness of the film layer, etc., and achieve good durability and service life. The effect of long, low coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0077] (1) 47.6kg of common PFA powder, 0.4kg of polyvinyl alcohol, 2kg of glycerin and 50kg of water are mixed to prepare a slurry;

[0078] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.4MPa, and the atomization air flow rate is 2m 3 / h, the inlet temperature is 320°C, and the outlet temperature is 100°C to obtain modified PFA powder S1.

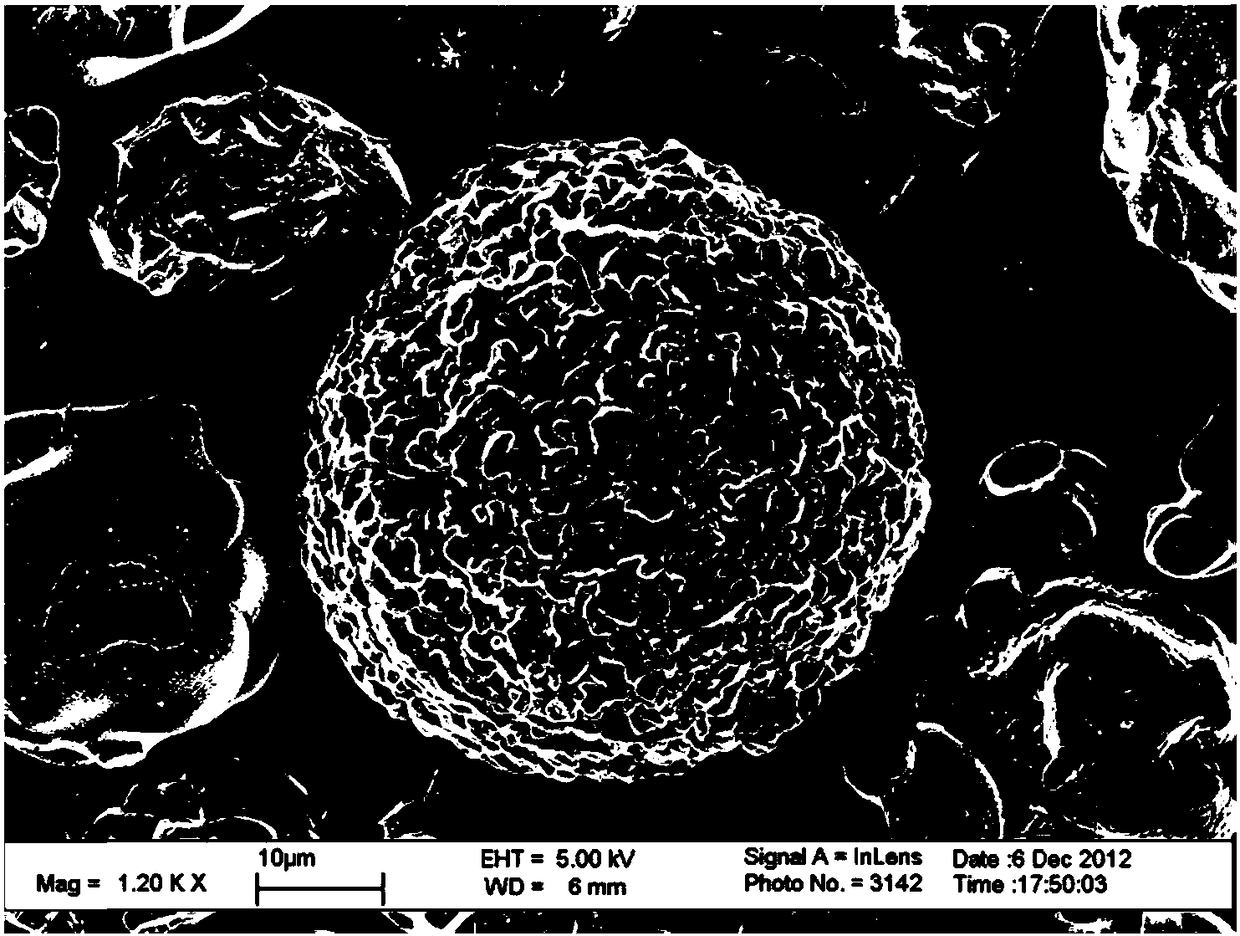

[0079] It is determined that the particle size D50 of the modified PFA powder is 52 μm, the sphericity of 96% of the powder is 95%, the fluidity is 15s / 50g, and the purity is 99.9%. The microscopic morphology of the modified PFA powder is shown in figure 1 shown.

preparation example 2

[0081] (1) 54.8kg common PFA powder, 0.2kg polyvinyl chloride, 3kg paraffin and 42kg water are mixed to prepare slurry;

[0082] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.3MPa, and the atomization air flow rate is 1m 3 / h, the inlet temperature is 300°C, and the outlet temperature is 60°C to obtain modified PFA powder S2.

[0083] It is determined that the particle size D50 of the modified PFA powder is 46 μm, the sphericity of 95% of the powder is 93%, the fluidity is 13s / 50g, and the purity is 99.5%.

preparation example 3

[0085] (1) 38.5kg common PFA powder, 0.5kg polyacrylate, 1kg graphite and 60kg water are mixed to prepare slurry;

[0086] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.5MPa, and the atomization air flow rate is 3m 3 / h, the inlet temperature is 350°C, and the air outlet temperature is 140°C to obtain modified PFA powder S3.

[0087] It is determined that the particle size D50 of the modified PFA powder is 59 μm, the sphericity of 95% of the powder is 98%, the fluidity is 18s / 50g, and the purity is 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com