Non-stick coating and method for its preparation, as well as pots and cooking equipment

A non-stick coating, pot technology, applied in the direction of coating, metal material coating process, kitchen utensils, etc., can solve the problems of coating life and application limitations, coating peeling, failure, low coating adhesion, etc. , to achieve high bonding strength, good wear resistance, good non-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] (1) 47.6kg of common PFA powder, 0.4kg of polyvinyl alcohol, 2kg of glycerin and 50kg of water are mixed to prepare a slurry;

[0068] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.4MPa, and the atomization air flow rate is 2m 3 / h, the inlet temperature is 320°C, and the outlet temperature is 100°C to obtain modified PFA powder S1.

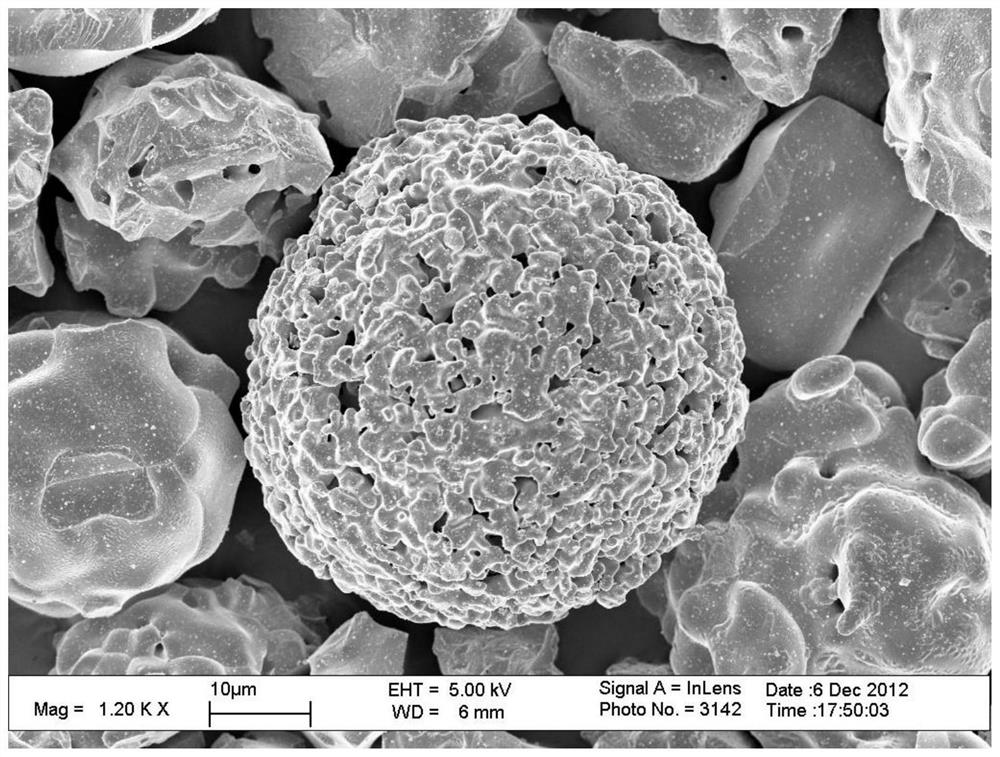

[0069] It is determined that the particle size D50 of the modified PFA powder is 52 μm, the sphericity of 96% of the powder is 95%, the fluidity is 15s / 50g, and the purity is 99.9%. The microscopic morphology of the modified PFA powder is shown in figure 1 shown.

preparation example 2

[0071] (1) 54.8kg common PFA powder, 0.2kg polyvinyl chloride, 3kg paraffin and 42kg water are mixed to prepare slurry;

[0072] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.3MPa, and the atomization air flow rate is 1m 3 / h, the inlet temperature is 300°C, and the outlet temperature is 60°C to obtain modified PFA powder S2.

[0073] It is determined that the particle size D50 of the modified PFA powder is 46 μm, the sphericity of 95% of the powder is 93%, the fluidity is 13s / 50g, and the purity is 99.5%.

preparation example 3

[0075] (1) 38.5kg common PFA powder, 0.5kg polyacrylate, 1kg graphite and 60kg water are mixed to prepare slurry;

[0076] (2) The slurry is subjected to airflow atomization drying treatment, wherein the conditions of airflow atomization drying include: the atomization pressure is 0.5MPa, and the atomization air flow rate is 3m 3 / h, the inlet temperature is 350°C, and the air outlet temperature is 140°C to obtain modified PFA powder S3.

[0077] It is determined that the particle size D50 of the modified PFA powder is 59 μm, the sphericity of 95% of the powder is 98%, the fluidity is 18s / 50g, and the purity is 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com