Epoxy vinyl ester micro compound resin and preparing method thereof

An epoxy vinyl ester and composite resin technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of difficult zinc stripping, difficult zinc stripping work, etc., saving manpower and time, and achieving significant economic benefits , The effect of improving the hardness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

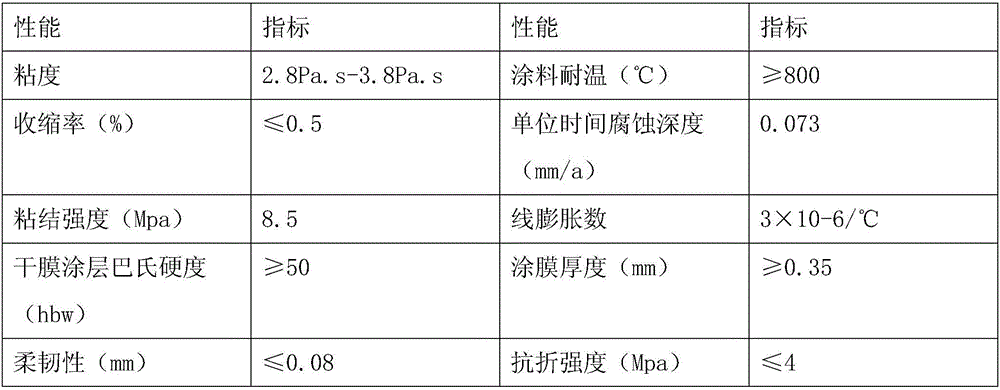

Image

Examples

Embodiment 1

[0027] A kind of preparation method of epoxy vinyl ester microcrystalline composite resin comprises the following steps:

[0028] (1) Weigh 80 parts of epoxy vinyl ester resin, 30 parts of 40 mesh acid-washed quartz sand, 5 parts of zinc stearate, and a defoamer composed of 70% polyoxypropylene glyceryl ether and 30% tetraethyl silicon 3 parts, 3 parts of organopolysiloxane with a molecular weight of 5000;

[0029] (2) Put the raw materials weighed in the step (1) into a mixing tank and mix and stir for 10 minutes;

[0030] (3) Add all the raw materials in step (2) to a high-speed disperser, and disperse for 15 minutes at a speed of 1000 rpm;

[0031] (4) Put all the raw materials in the step (3) into a grinder and grind for 10 minutes;

[0032] (5) Pack all the raw materials in step (4), and store in a cool and dry place for later use.

Embodiment 2

[0034] A kind of preparation method of epoxy vinyl ester microcrystalline composite resin comprises the following steps:

[0035] (1) Weigh 200 parts of epoxy vinyl ester resin, 80 parts of 80 mesh acid-washed quartz sand, 15 parts of zinc stearate, and a defoamer composed of 90% polyoxypropylene glyceryl ether and 10% tetraethyl silicon 10 parts, 10 parts of organopolysiloxane with a molecular weight of 15000;

[0036] (2) Put the raw materials weighed in the step (1) into a mixing tank and mix and stir for 20 minutes;

[0037] (3) Add all the raw materials in step (2) to a high-speed disperser, and disperse for 30 minutes at a speed of 1000 rpm;

[0038] (4) Put all the raw materials in the step (3) into a grinder and grind for 15 minutes;

[0039] (5) Pack all the raw materials in step (4), and store in a cool and dry place for later use.

Embodiment 3

[0041] A kind of preparation method of epoxy vinyl ester microcrystalline composite resin comprises the following steps:

[0042] (1) Weigh 120 parts of epoxy vinyl ester resin, 55 parts of 60-mesh acid-washed quartz sand, 10 parts of zinc stearate, and a defoamer composed of 80% polyoxypropylene glyceryl ether and 20% tetraethyl silicon 6 parts, 6 parts of organopolysiloxane with a molecular weight of 10000;

[0043] (2) Put the raw materials weighed in the step (1) into a mixing tank and mix and stir for 15 minutes;

[0044] (3) Add all the raw materials in step (2) to a high-speed disperser, and disperse for 22 minutes at a speed of 1000 rpm;

[0045] (4) Put all the raw materials in the step (3) into a grinder and grind for 12 minutes;

[0046] (5) Pack all the raw materials in step (4), and store in a cool and dry place for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com