Treatment method for surface of carbon fiber resin-based composite material

A carbon fiber resin-based, composite material technology, applied in the field of new materials, can solve the problems of time and cost loss, high cost, air pollution, etc., and achieve the effects of less processing time, less resin content, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

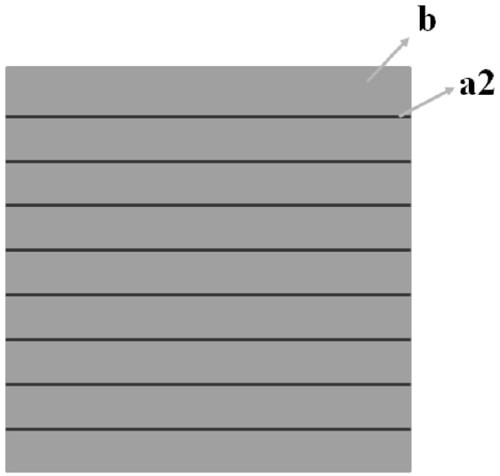

[0038] Use sandpaper with a mesh number of 200 to roughly grind the surface of the carbon fiber resin matrix composite material 1, and the direction of grinding and polishing is as follows: figure 2 As shown, the grease layer on the surface of the carbon fiber resin matrix composite was preliminarily removed.

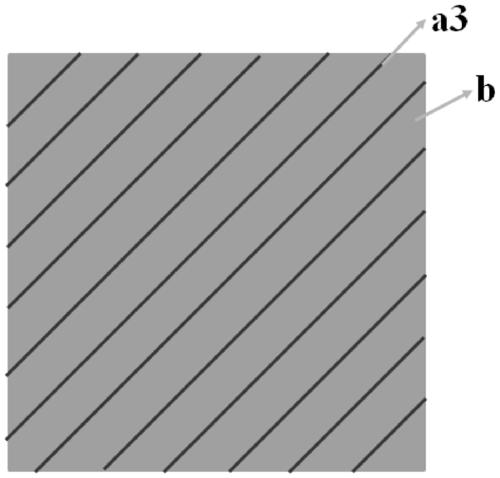

[0039] Use sandpaper with a mesh number of 400 to roughly grind the surface of the carbon fiber resin matrix composite material 2, and the direction of grinding and polishing is as follows: image 3 As shown, rotate 45 degrees counterclockwise to remove traces using mesh 200.

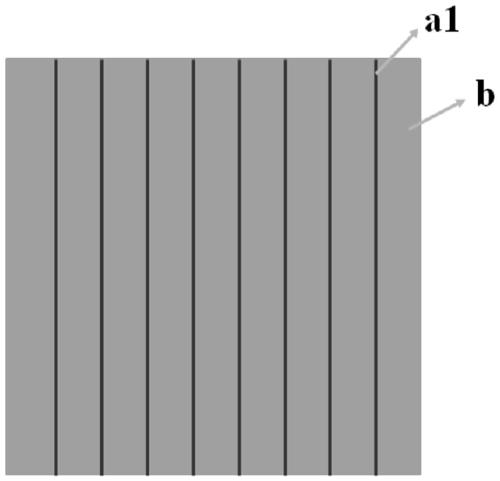

[0040] Use sandpaper with a mesh number of 600 to roughly grind the surface of the carbon fiber resin matrix composite material 3, and the direction of grinding and polishing is as follows: figure 1 As shown, rotate 45 degrees counterclockwise to remove traces using mesh 400.

[0041] Use 800-mesh sandpaper to finely grind the surface of the composite material, and the direction of the fine gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com