Corrosion-resistant and wear-resistant coating with gradient composite structure and preparation method thereof

A technology of combined structure and wear-resistant coating, applied in the direction of coating, metal material coating process, etc., can solve the problems of difficult operation and high cost, and achieve the effect of improving strength, hardness, and fine grain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Powder Preparation

[0039] The raw material of the wear-resistant and corrosion-resistant alloy coating is metal powder with a particle size of 45-75 μm, and its proportion is: Co:Cr:Ni:Fe:Ti=22.5:22.5:22.5:22.5:10 (atomic ratio).

[0040] Step 2: Substrate surface pretreatment

[0041] The first is to soak the base Q235 steel in the acid solution, the soaking time is determined according to the degree of dirt on the workpiece, and rinse with water after acid leaching. Then soak it in alkaline water to neutralize the residual acid, and finally wash it thoroughly with warm water and dry it. Then use the conventional sandblasting roughening method to roughen the surface of the workpiece.

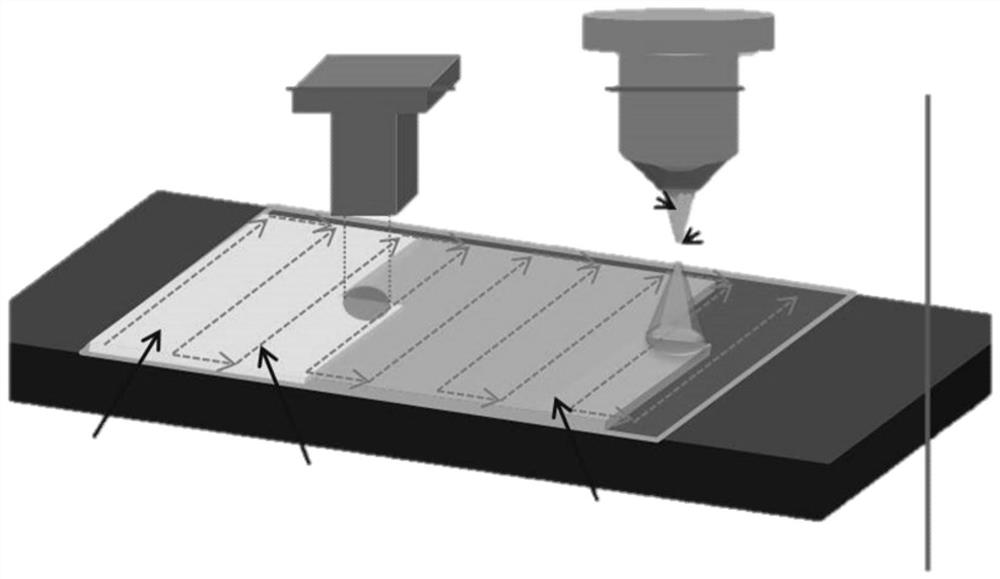

[0042] Step 3: Plasma Cladding

[0043] Such as figure 1 As shown, in the implementation, first place the base Q235 steel on the workbench, adopt the method of plasma cladding, through the method of coaxial powder feeding, cladding the alloy powder prepared in step 1 on the...

Embodiment 2

[0048] Step 1: Powder Preparation

[0049] The raw material of the wear-resistant and corrosion-resistant alloy coating is metal powder with a particle size of 45-75 μm, and its ratio is: Co: Cr: Fe: Ni: Ti: Al: Cu = 20: 20: 20: 20: 10: 5: 5 (atomic ratio).

[0050] Step 2: Substrate surface pretreatment

[0051] The first is to soak the base Q235 steel in the acid solution, the soaking time is determined according to the degree of dirt on the workpiece, and rinse with water after acid leaching. Then soak it in alkaline water to neutralize the residual acid, and finally wash it thoroughly with warm water and dry it. Then use the conventional sandblasting roughening method to roughen the surface of the workpiece.

[0052] Step 3: Plasma Cladding

[0053] The plasma cladding process parameters are: voltage 50V, current 90A, cladding distance 8mm, cladding speed 400mm / min, powder feeding speed 20g / min, average hardness of cladding layer 620HV 0.1 .

[0054] Step 4: Laser Re...

Embodiment 3

[0058] Step 1: Powder Preparation

[0059] The raw material of wear-resistant and corrosion-resistant alloy coating is metal and ceramic powder with a particle size of 45-75 μm, and the ratio is: Co: Cr: Fe: Ni: Ti: Al: Cu: TiC: WC: TiB 2 =20:20:20:20:10:2:2:2:2:2 (atomic ratio).

[0060] Step 2: Substrate surface pretreatment

[0061] The first is to soak the base Q235 steel in the acid solution, the soaking time is determined according to the degree of dirt on the workpiece, and rinse with water after acid leaching. Then soak it in alkaline water to neutralize the residual acid, and finally wash it thoroughly with warm water and dry it. Then use the conventional sandblasting roughening method to roughen the surface of the workpiece.

[0062] Step 3: Plasma Cladding

[0063] The plasma cladding process parameters are: voltage 60V, current 150A, cladding distance 12mm, cladding speed 600mm / min, powder feeding speed 30g / min; average hardness of the cladding layer is 900HV ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com